- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Benefits of Using Steel Grating Platforms for Industrial Applications and Construction Projects

Steel Grating Platforms An Overview of Their Importance and Applications

Steel grating platforms have become a central element in various industries, offering safety, durability, and versatility. These platforms are constructed from steel bars arranged in a grid pattern, creating a surface that is both functional and robust. As industries strive for efficiency and safety in their operations, understanding the significance and applications of steel grating platforms becomes paramount.

One of the primary advantages of steel grating platforms is their ability to provide a safe working environment. The gap between the bars allows for easy drainage of liquids and debris, minimizing the risk of slips and falls. This is particularly important in industrial settings where spills can occur frequently. The open design ensures that workers are less likely to encounter hazards while moving around the platform, making it a preferred choice in factories, warehouses, and processing plants.

Furthermore, steel grating platforms are designed for heavy load-bearing capacities. The strength of steel allows these platforms to support substantial weights without compromising integrity. This makes them ideal for use in scenarios where machinery, equipment, or large quantities of materials are regularly transported or stored. Industries such as construction, oil and gas, and chemical processing benefit significantly from the durability and load-handling capabilities of steel grating.

Another noteworthy aspect of steel grating platforms is their resistance to environmental factors. Steel grating is often galvanized or coated with protective finishes to enhance its resistance to corrosion and rust. This makes steel grating platforms suitable for outdoor applications or in environments where exposure to moisture and chemicals is a concern. The longevity of these platforms means they require less frequent replacement, thereby reducing costs in the long term.

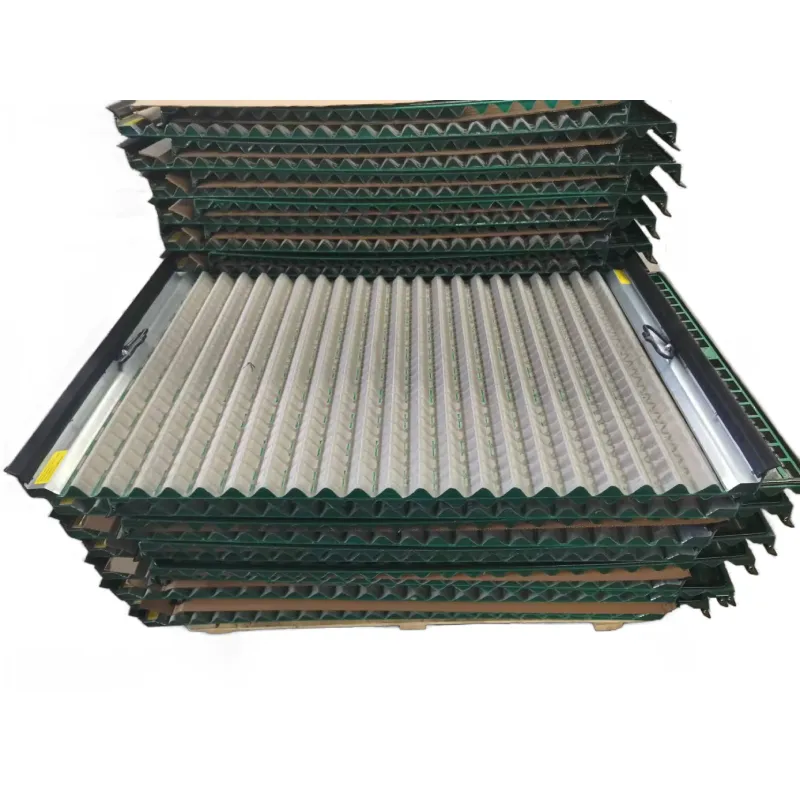

steel grating platform

In terms of design and versatility, steel grating platforms can be customized to meet the specific needs of different applications. Various types of grating, such as welded, riveted, or press-locked options, provide different levels of strength and weight capacities. Additionally, platforms can be made in various thicknesses and mesh sizes to accommodate particular load specifications and safety requirements. This customizability allows for seamless integration into different operational setups, whether for elevated walkways, maintenance platforms, or machinery support.

Moreover, the installation process of steel grating platforms is relatively straightforward. Depending on the application's complexity, grating sections can be easily cut to size and mounted on existing structures or frameworks. This ease of installation can significantly reduce downtime in industrial settings, enabling businesses to maintain productivity levels without extensive interruptions.

Sustainability is another consideration in the modern industrial landscape, and steel grating platforms align well with eco-friendly initiatives. Steel is a recyclable material, and many manufacturers utilize recycled steel in their products. By opting for steel grating platforms, industries not only benefit from the material's robustness but also contribute to sustainability efforts by reducing waste and promoting the recycling of materials.

In summary, steel grating platforms serve as a vital component in numerous industrial applications. Their ability to provide a safe working environment, support heavy loads, resist environmental factors, and offer customization options makes them indispensable across various sectors. As industries continue to evolve and seek effective solutions for operational challenges, steel grating platforms will undoubtedly remain a foundational element in enhancing safety and efficiency. Investing in high-quality steel grating is not merely a matter of compliance; it is a strategic enhancement that can lead to improved productivity, reduced risks, and a better return on investment. As the demand for reliable infrastructure grows, the role of steel grating platforms in shaping these environments will only become more prominent, standing as a testament to engineering excellence and enduring reliability.

-

Upgrade Your Industrial Operations with Durable Steel GratingNewsJul.21,2025

-

Transform Your Flooring Solutions with Quality Floor GratingNewsJul.21,2025

-

Top-Quality Shale Shaker Screens for Your Drilling NeedsNewsJul.21,2025

-

High-Quality Steel Grating for All Your Industrial NeedsNewsJul.21,2025

-

Explore the Durability and Versatility of Galvanized Steel GratingNewsJul.21,2025

-

Ensure Maximum Safety with Premium Safety NetsNewsJul.21,2025