- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

shaker screen mesh

Understanding Shaker Screen Mesh An Essential Component in Drilling Operations

In the world of drilling, especially in the oil and gas industry, efficiency and precision are paramount. One crucial element that significantly contributes to these factors is the shaker screen mesh. This article delves into the importance of shaker screen mesh, its types, applications, and the role it plays in enhancing the drilling process.

What is Shaker Screen Mesh?

Shaker screen mesh refers to the filtering material used in shale shakers, which are integral pieces of equipment in the drilling process. Shale shakers are utilized to separate drilling cuttings from the drilling fluid (or mud). The screen mesh serves as the barrier that allows the fluid to pass while retaining solid particles, thereby ensuring the recycling of the drilling fluid, which is vital for maintaining the efficiency of the drilling operation.

Types of Shaker Screen Mesh

Shaker screen meshes come in various types and specifications, tailored to different drilling needs. The most common types include

1. Wire Mesh Screens These are the traditional type of screens made of woven wire cloth. They are available in different mesh sizes and are known for their durability and ease of maintenance. Wire mesh screens are often used in various drilling applications due to their versatility.

2. Synthetic Screens Made from advanced materials like polyurethane or other polymers, synthetic screens are designed to provide superior performance. They are often more cost-effective in the long run as they tend to have a longer lifespan and require less frequent replacement.

3. Composite Screens These screens combine the benefits of both wire and synthetic materials. They typically consist of a wire mesh frame covered with a synthetic layer, offering both strength and flexibility. Composite screens are preferred in extreme drilling conditions due to their resilience.

Applications of Shaker Screen Mesh

shaker screen mesh

Shaker screen meshes are primarily used in the oil and gas industry, but their applications extend to other fields such as

- Mining In mineral extraction, shaker screens help separate valuable materials from waste. - Waste Management They are employed in wastewater treatment facilities to filter solids from liquids.

- Environmental Protection Shaker screens play a role in managing drilling mud waste, helping to control the environmental impact of drilling operations.

The Importance of Choosing the Right Mesh

Selecting the appropriate shaker screen mesh is crucial for the success of any drilling operation. The choice of mesh size can impact the effectiveness of the drilling fluid, the rate of penetration, and overall drilling efficiency. A finer mesh will retain more solids, which can lead to better fluid quality but may also decrease fluid flow rate. Conversely, a coarser mesh allows for quicker fluid flow but might let too many solids pass through.

Factors to consider when choosing the right screen mesh include

- Particle Size Understanding the size of the drilled cuttings and selecting a mesh that can efficiently separate them from the fluid. - Fluid Property Different fluids may require different mesh specifications to maintain optimal drilling performance.

- Operational Conditions High-temperature and high-pressure environments may necessitate the use of specific screen materials that can withstand such conditions.

Conclusion

In conclusion, shaker screen mesh is a vital component in the drilling industry, ensuring efficient separation of solids from drilling fluids. With advances in technology, the variety of meshes available today allows operators to tailor their choices according to specific needs. By carefully selecting the appropriate shaker screen mesh, drilling companies can enhance their operational efficiency, reduce costs, and mitigate environmental impacts. As the industry continues to evolve, the role of shaker screen mesh will remain indispensable in achieving successful drilling operations.

-

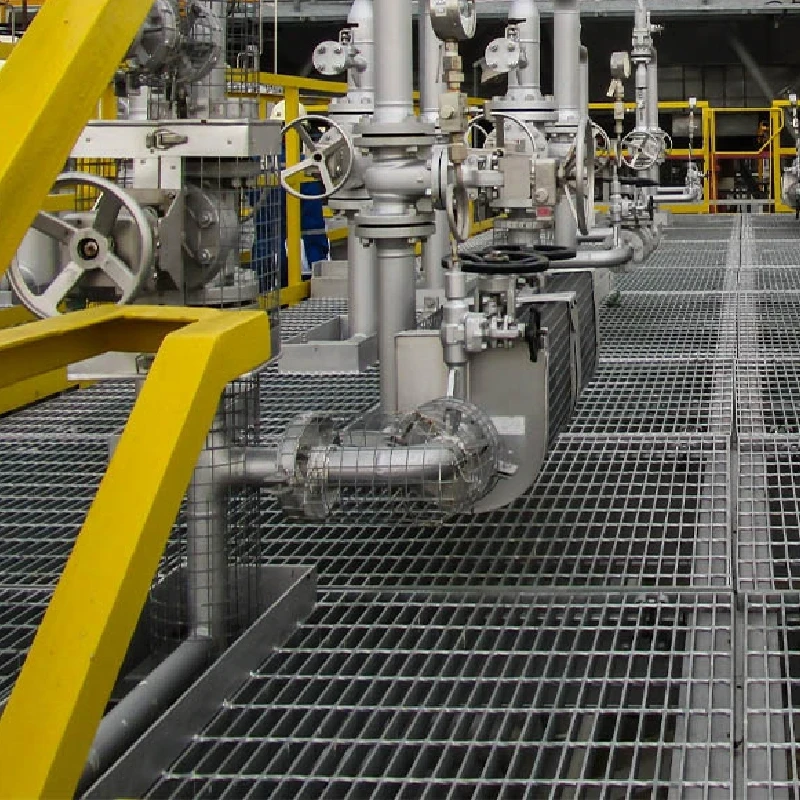

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025