- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Fev . 18, 2025 05:27

Back to list

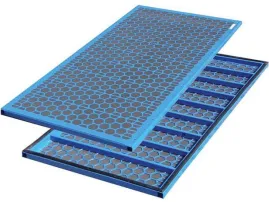

cost of steel grating

Understanding the cost of steel grating is crucial for anyone involved in construction or industrial projects. Steel grating is a versatile and essential component used across various sectors, from urban infrastructure to commercial buildings. It offers unique advantages like high strength, durability, and an exceptional cost-to-performance ratio, but understanding the comprehensive costs involved is key to effective budgeting and project planning.

Once manufactured, steel grating must be transported from the production facility to the site. It involves logistical considerations like packaging, loading, and shipping costs, which vary based on the distance, weight, and geographical challenges. Bulk ordering can sometimes reduce the per-unit cost, but adequate storage facilities are critical to avoid additional storage expenses. It's crucial to work with logistics partners who understand the unique requirements of transporting heavy materials to ensure efficiency and safety. 4. Installation Costs Installation is another significant cost factor. It includes labor for placement and securing of the grating, which varies depending on project complexity and the environment in which the grating will be installed. Projects in high or confined areas may require specialized equipment and skills, leading to increased labor costs. Employing skilled professionals ensures proper installation, crucial for the grating's performance and longevity. 5. Maintenance and Lifecycle Costs While steel grating is durable, it requires periodic maintenance to prolong its lifespan. Factors like the environment, load stress, and whether the grating is indoors or outdoors affect maintenance needs. Regular inspections and cleaning are necessary to prevent corrosion and wear. Investing in high-quality materials initially may incur higher costs, but it reduces the need for frequent replacements or repairs, offering cost-efficiency in the long run. Understanding these cost metrics from various perspectives – experience from real-world projects, expertise in material science, authority in sourcing, and trust in transparent transaction processes – builds a strong foundation for making cost-effective decisions. Starting with a clear assessment of project requirements and aligning them with a strategic selection of materials and partners enhances both the economic and operational success of projects using steel grating. Balancing upfront costs with long-term benefits ensures that financial resources are efficiently utilized, achieving the desired outcomes within budget constraints.

Once manufactured, steel grating must be transported from the production facility to the site. It involves logistical considerations like packaging, loading, and shipping costs, which vary based on the distance, weight, and geographical challenges. Bulk ordering can sometimes reduce the per-unit cost, but adequate storage facilities are critical to avoid additional storage expenses. It's crucial to work with logistics partners who understand the unique requirements of transporting heavy materials to ensure efficiency and safety. 4. Installation Costs Installation is another significant cost factor. It includes labor for placement and securing of the grating, which varies depending on project complexity and the environment in which the grating will be installed. Projects in high or confined areas may require specialized equipment and skills, leading to increased labor costs. Employing skilled professionals ensures proper installation, crucial for the grating's performance and longevity. 5. Maintenance and Lifecycle Costs While steel grating is durable, it requires periodic maintenance to prolong its lifespan. Factors like the environment, load stress, and whether the grating is indoors or outdoors affect maintenance needs. Regular inspections and cleaning are necessary to prevent corrosion and wear. Investing in high-quality materials initially may incur higher costs, but it reduces the need for frequent replacements or repairs, offering cost-efficiency in the long run. Understanding these cost metrics from various perspectives – experience from real-world projects, expertise in material science, authority in sourcing, and trust in transparent transaction processes – builds a strong foundation for making cost-effective decisions. Starting with a clear assessment of project requirements and aligning them with a strategic selection of materials and partners enhances both the economic and operational success of projects using steel grating. Balancing upfront costs with long-term benefits ensures that financial resources are efficiently utilized, achieving the desired outcomes within budget constraints.

Share

Next:

Latest news

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025