- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Fev . 15, 2025 04:25

Back to list

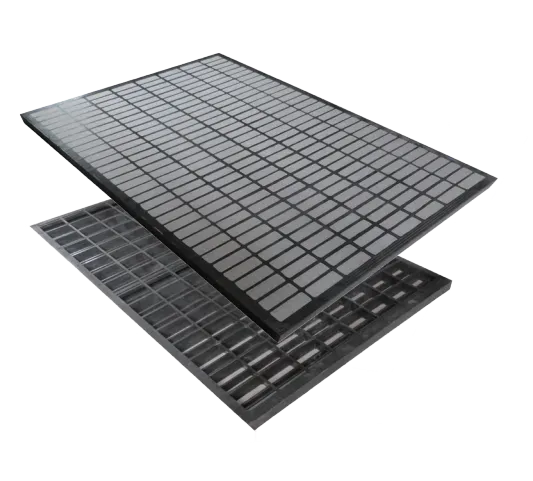

heavy-duty welded bar grating

When embarking on a project that requires durable and efficient platforms, bar grating platforms often emerge as the unrivaled choice. The reasons lie in their strength, versatility, and wide-ranging applications across various industries. From industrial settings to transportation hubs, bar grating platforms provide a critical solution for environments that demand robust and reliable structures.

In terms of expertise, understanding the specific types of bar grating available can enhance the selection process. Press-locked, weld-locked, and swage-locked gratings each have attributes suited to particular environments. Weld-locked gratings, for instance, offer additional strength through a series of welded connections, making them suitable for heavy industrial applications where higher loads are commonplace. As an authoritative voice in material selection, consider the longevity of various coatings, such as galvanized or powder-coated finishes, which significantly extend the service life of the grating platforms. Galvanization, in particular, provides an additional layer of protection against rust and corrosion, thereby extending the lifespan of these platforms in outdoor or exposed environments. Credibility and trust in these platforms are established not only through their widespread industrial use but also through rigorous testing and standards compliance. Many bar grating platforms adhere to strict guidelines, such as those set by the Occupational Safety and Health Administration (OSHA) or the American Institute of Steel Construction (AISC), ensuring they meet the safety and performance standards expected of them in demanding applications. Ultimately, the decision to implement bar grating platforms should involve a thorough consultation with industry professionals who can provide insights based on years of experience. This approach ensures that the platform not only meets the immediate needs but also aligns with long-term strategic goals, whether for safety enhancement, operational efficiency, or environmental considerations. In summary, bar grating platforms stand as a testament to advancements in engineering and material science, tailored by decades of expert application and quality assurance. They represent an investment in structural dependability and safety—one that undeniably meets the rigorous demands of the modern industrial world. Whether in manufacturing floors, vehicle test tracks, or staircases in public infrastructure, these platforms continue to prove their merit, providing peace of mind in both their performance and reliability.

In terms of expertise, understanding the specific types of bar grating available can enhance the selection process. Press-locked, weld-locked, and swage-locked gratings each have attributes suited to particular environments. Weld-locked gratings, for instance, offer additional strength through a series of welded connections, making them suitable for heavy industrial applications where higher loads are commonplace. As an authoritative voice in material selection, consider the longevity of various coatings, such as galvanized or powder-coated finishes, which significantly extend the service life of the grating platforms. Galvanization, in particular, provides an additional layer of protection against rust and corrosion, thereby extending the lifespan of these platforms in outdoor or exposed environments. Credibility and trust in these platforms are established not only through their widespread industrial use but also through rigorous testing and standards compliance. Many bar grating platforms adhere to strict guidelines, such as those set by the Occupational Safety and Health Administration (OSHA) or the American Institute of Steel Construction (AISC), ensuring they meet the safety and performance standards expected of them in demanding applications. Ultimately, the decision to implement bar grating platforms should involve a thorough consultation with industry professionals who can provide insights based on years of experience. This approach ensures that the platform not only meets the immediate needs but also aligns with long-term strategic goals, whether for safety enhancement, operational efficiency, or environmental considerations. In summary, bar grating platforms stand as a testament to advancements in engineering and material science, tailored by decades of expert application and quality assurance. They represent an investment in structural dependability and safety—one that undeniably meets the rigorous demands of the modern industrial world. Whether in manufacturing floors, vehicle test tracks, or staircases in public infrastructure, these platforms continue to prove their merit, providing peace of mind in both their performance and reliability.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025