- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

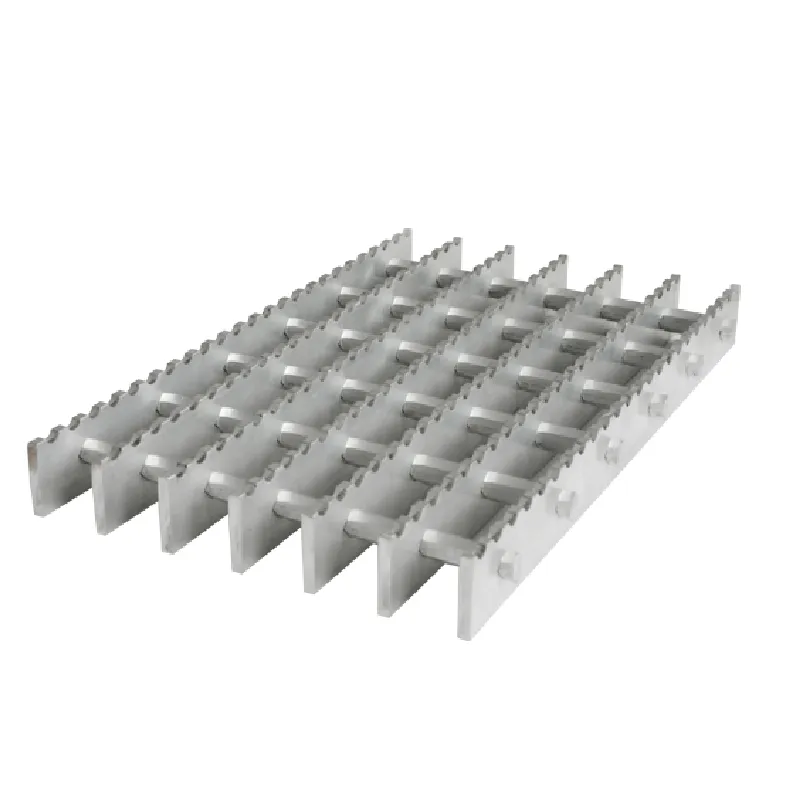

grating galv iron

Understanding Grating Galvanized Iron Properties, Uses, and Benefits

Grating galvanized iron is a crucial material widely used in various industries due to its strength, durability, and resistance to corrosion. Galvanization, a process where a protective zinc coating is applied to iron or steel, greatly enhances the lifespan and performance of metal products, making them ideal for both indoor and outdoor applications.

What is Grating Galvanized Iron?

Grating galvanized iron refers to a form of metal grating that has undergone galvanization. This grating typically consists of a series of parallel bars created from galvanized iron or steel, allowing for the effective passage of light, air, and water while providing a sturdy surface that can withstand heavy loads. The combination of grating and galvanization results in a product that can handle harsh environments while maintaining structural integrity.

Properties of Grating Galvanized Iron

1. Corrosion Resistance One of the most significant benefits of galvanized iron is its resistance to corrosion. The zinc layer acts as a sacrificial anode, protecting the underlying iron or steel from rusting, which is particularly crucial in areas exposed to moisture.

2. Strength and Durability Grating galvanized iron boasts high tensile strength and load-bearing capacity, making it suitable for a variety of applications, including flooring, walkways, and platforms.

3. Lightweight Despite its strength, galvanized iron grating is relatively lightweight compared to solid panels, making it easier to handle, install, and maintain.

grating galv iron

Applications of Grating Galvanized Iron

1. Industrial Flooring In manufacturing and processing plants, grating galvanized iron is commonly used for flooring due to its slip-resistant surface and ability to allow for drainage. It is particularly effective in areas where spills are common.

2. Walkways and Platforms Grating galvanized iron is an excellent choice for walkways, providing safe and stable passage in both industrial and commercial settings.

3. Drainage Systems The open design of grating allows for efficient drainage, making it suitable for grates over pits and drainage channels.

4. Security Fencing In some contexts, grating galvanized iron can be utilized in constructing secure fencing that allows visibility while providing a barrier against intruders.

Conclusion

Grating galvanized iron stands out as a versatile and durable option for various applications across multiple industries. Its corrosion resistance, strength, and low maintenance requirements make it an ideal choice for environments that demand resilience and reliability. Whether used in industrial operations or as part of architectural design, the benefits of grating galvanized iron are clear. By choosing this material, companies can ensure both longevity and satisfactory performance, contributing to the overall safety and functionality of their projects. As advancements continue in material science, the applications for grating galvanized iron are likely to expand even further, reinforcing its place as a staple in construction and manufacturing.

-

Welded Steel Bar Grating: The Strongest Choice for Industrial FlooringNewsMay.21,2025

-

Steel Grating for Sale: The Ultimate Anti-Slip SolutionNewsMay.21,2025

-

Steel Frame Shaker Screens: Unmatched Durability for Demanding OperationsNewsMay.21,2025

-

Shaker Screens: Your Ultimate Solution for Oil & Gas FiltrationNewsMay.21,2025

-

Press Locked Steel Grating: The Smarter Choice for Heavy-Duty FlooringNewsMay.21,2025

-

Helicopter Deck Safety Nets: Protect Your Crew and EquipmentNewsMay.21,2025