- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

lut . 18, 2025 11:28

Back to list

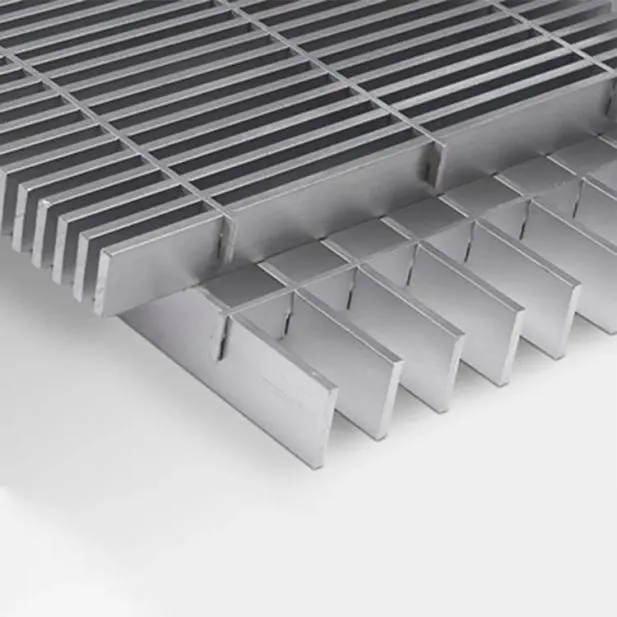

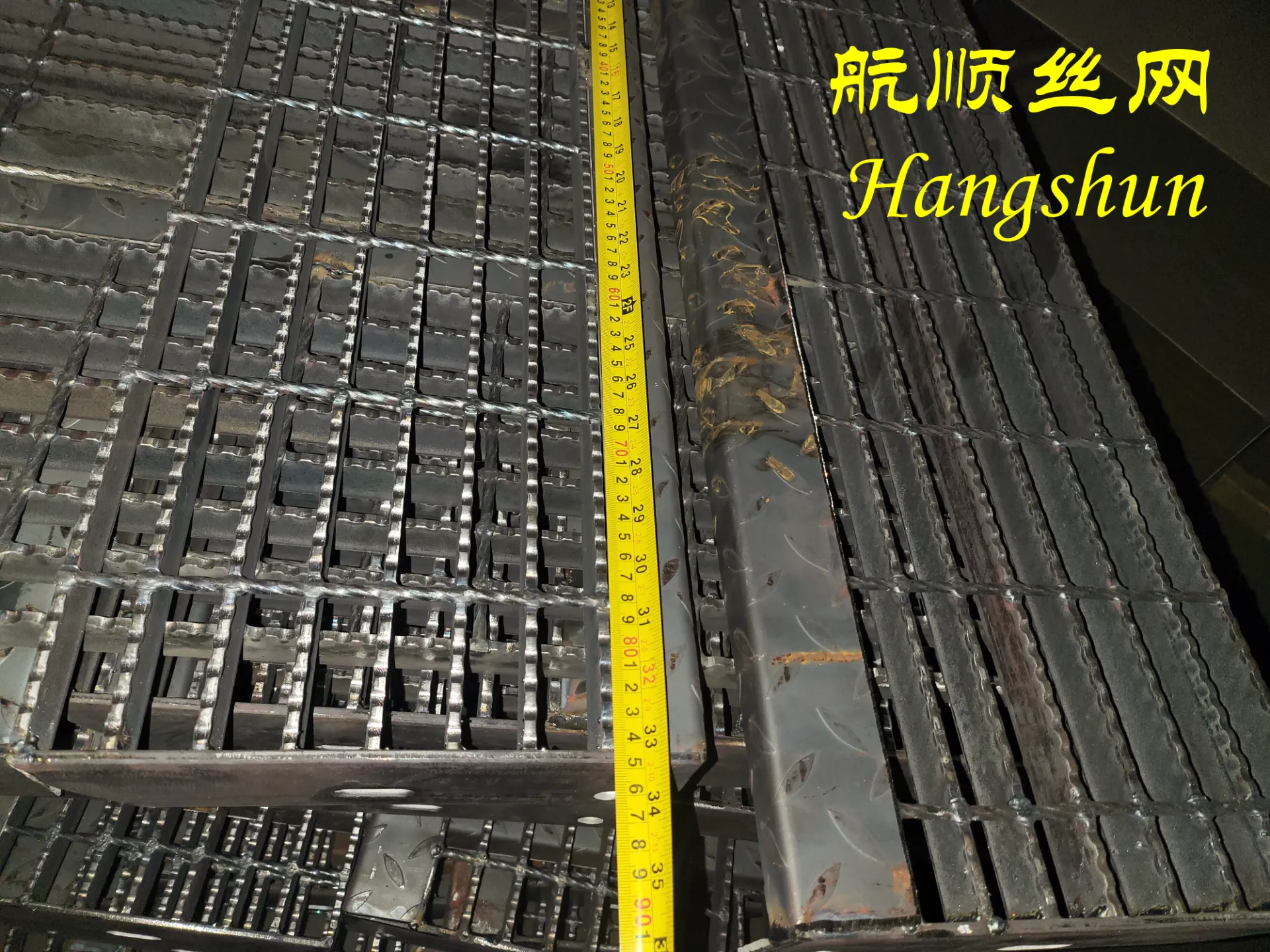

Press-Locked Steel Grating

Navigating the landscape of galvanised grating prices can be a complex affair, with various factors influencing costs and impacting purchasing decisions. For businesses and individuals looking to make informed decisions, understanding the nuances of this industry requires not just price comparison but a deeper dive into quality, application, and market trends.

Incorporating third-party quality inspections and lifespan assessments into the purchasing process can enhance trustworthiness. These independent evaluations provide unbiased insights into the grating's performance, helping buyers avoid substandard products that could fail under pressure. This not only secures infrastructure investments but also aids in maintaining functional and safe industrial environments. As environmental sustainability gains prominence, the eco-footprint of galvanised gratings is becoming an influential factor for consumers. Seeking products made from recycled materials or those produced using sustainable practices can be cost-effective in the long run, aligning with socially responsible business strategies. Moreover, selecting suppliers who prioritize environmentally friendly production emphasizes an organization’s commitment to sustainability, potentially expanding opportunities with clients who value green initiatives. To maximize returns on investment, buyers should consider the longevity and lifecycle cost analysis of galvanised grating. Instead of focusing solely on the initial purchase price, evaluating the maintenance costs, potential downtimes due to corrosion, and replacement frequencies provides a more comprehensive understanding of the grating's financial impact over time. Lastly, leveraging digital tools and platforms for sourcing galvanised grating pricing information can be beneficial. Online databases, supplier directories, and e-commerce platforms offer extensive resources for comparing options, reading reviews, and accessing all-inclusive bids, granting businesses the power to negotiate better deals. In summary, while the price of galvanised grating is pivotal, an emphasis on quality, adherence to standards, and environmental considerations should form the foundation of a well-informed purchasing strategy. Through a balanced approach integrating expert insights, authoritative sourcing, and trustworthy evaluations, stakeholders can ensure that their investment not only meets immediate needs but also aligns with broader organizational goals.

Incorporating third-party quality inspections and lifespan assessments into the purchasing process can enhance trustworthiness. These independent evaluations provide unbiased insights into the grating's performance, helping buyers avoid substandard products that could fail under pressure. This not only secures infrastructure investments but also aids in maintaining functional and safe industrial environments. As environmental sustainability gains prominence, the eco-footprint of galvanised gratings is becoming an influential factor for consumers. Seeking products made from recycled materials or those produced using sustainable practices can be cost-effective in the long run, aligning with socially responsible business strategies. Moreover, selecting suppliers who prioritize environmentally friendly production emphasizes an organization’s commitment to sustainability, potentially expanding opportunities with clients who value green initiatives. To maximize returns on investment, buyers should consider the longevity and lifecycle cost analysis of galvanised grating. Instead of focusing solely on the initial purchase price, evaluating the maintenance costs, potential downtimes due to corrosion, and replacement frequencies provides a more comprehensive understanding of the grating's financial impact over time. Lastly, leveraging digital tools and platforms for sourcing galvanised grating pricing information can be beneficial. Online databases, supplier directories, and e-commerce platforms offer extensive resources for comparing options, reading reviews, and accessing all-inclusive bids, granting businesses the power to negotiate better deals. In summary, while the price of galvanised grating is pivotal, an emphasis on quality, adherence to standards, and environmental considerations should form the foundation of a well-informed purchasing strategy. Through a balanced approach integrating expert insights, authoritative sourcing, and trustworthy evaluations, stakeholders can ensure that their investment not only meets immediate needs but also aligns with broader organizational goals.

Share

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025