- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

lut . 06, 2025 05:49

Back to list

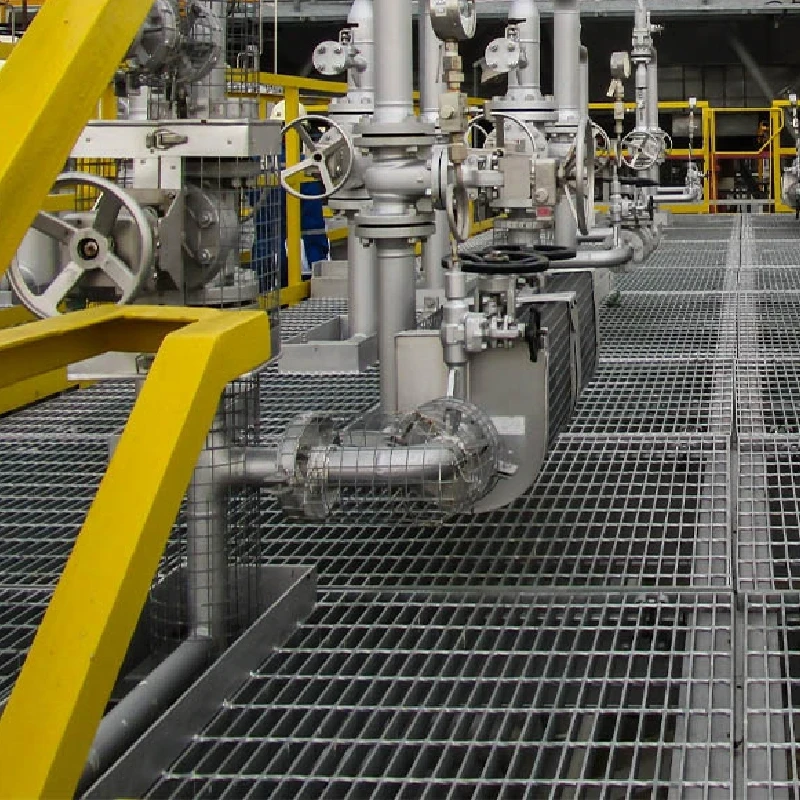

Riveted Grating

Understanding the intricacies of floor grating prices is pivotal for architects, builders, and purchasing departments aiming to optimize both budget and functional efficiency. After years of experience analyzing market trends and consulting with manufacturers, obtaining a comprehensive understanding of what influences floor grating prices can significantly impact the choice of materials and suppliers.

The geographic location of raw materials and manufacturing facilities critically impacts freight costs, affecting the final price even before the grating reaches the consumer. Proximity to major production hubs can lead to significant savings on logistics, making it essential for procurement teams to consider local suppliers when price-sensitivity is paramount. Regulatory standards and certifications are imperative in specific industries, ensuring that floor grating adheres to safety and performance regulations. Complying with stringent standards, such as ASTM or OSHA, often necessitates additional testing and certification processes, reflecting in higher prices but offering invaluable reliability and safety assurance. Advancements in technology and sustainable practices in manufacturing provide avenues for cost reductions and efficiency enhancements. Innovative production techniques and economies of scale influence pricing dynamics, enabling suppliers to offer competitive rates while maintaining quality standards. Trust in a supplier's expertise and authoritative standing in the market is essential, underscoring the importance of selecting partners with a proven track of reliability and adherence to best practices. Reading through customer testimonials, reviewing past project case studies, and validating industry experience can offer assurance in pricing's fairness relative to the value received. Purchasers need to balance between price and quality, ensuring that floor grating meets both budgetary constraints and functional requirements. Understanding the complexity of pricing factors ensures informed decision-making and aligns procurement strategies with organizational objectives, guaranteeing optimal performance and longevity for the applications served by the chosen floor grating solution.

The geographic location of raw materials and manufacturing facilities critically impacts freight costs, affecting the final price even before the grating reaches the consumer. Proximity to major production hubs can lead to significant savings on logistics, making it essential for procurement teams to consider local suppliers when price-sensitivity is paramount. Regulatory standards and certifications are imperative in specific industries, ensuring that floor grating adheres to safety and performance regulations. Complying with stringent standards, such as ASTM or OSHA, often necessitates additional testing and certification processes, reflecting in higher prices but offering invaluable reliability and safety assurance. Advancements in technology and sustainable practices in manufacturing provide avenues for cost reductions and efficiency enhancements. Innovative production techniques and economies of scale influence pricing dynamics, enabling suppliers to offer competitive rates while maintaining quality standards. Trust in a supplier's expertise and authoritative standing in the market is essential, underscoring the importance of selecting partners with a proven track of reliability and adherence to best practices. Reading through customer testimonials, reviewing past project case studies, and validating industry experience can offer assurance in pricing's fairness relative to the value received. Purchasers need to balance between price and quality, ensuring that floor grating meets both budgetary constraints and functional requirements. Understanding the complexity of pricing factors ensures informed decision-making and aligns procurement strategies with organizational objectives, guaranteeing optimal performance and longevity for the applications served by the chosen floor grating solution.

Share

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

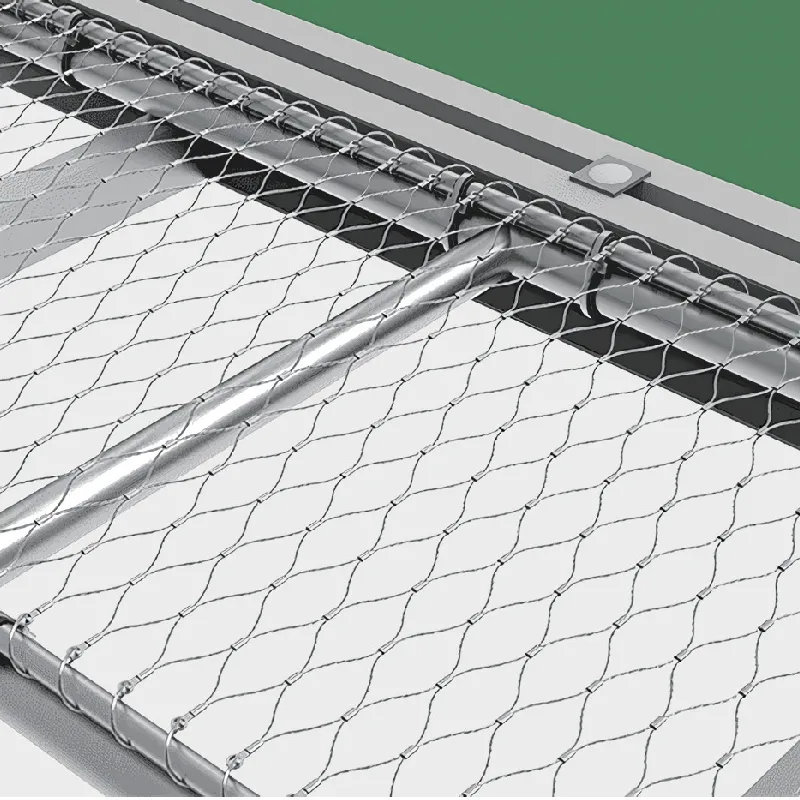

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025