- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

sty . 20, 2025 15:17

Back to list

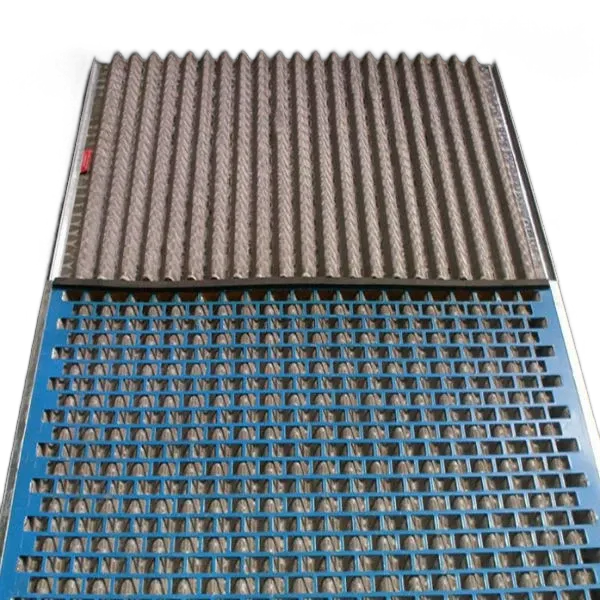

Welded Steel Grating

Choosing the right materials for industrial flooring and surfaces can greatly impact the efficiency, safety, and overall functionality of a space. One material that stands out due to its unique blend of qualities is aluminium bar grating. Highly regarded for its lightweight nature, corrosion resistance, and excellent strength-to-weight ratio, aluminium bar grating is extensively used in numerous applications from commercial to industrial settings.

Load distribution and safety are other key considerations where aluminium bar grating excels. The flat, serrated surface of the grating provides excellent traction even in wet or oily conditions, thereby reducing slip and fall risks. For industrial facilities where worker safety is paramount, choosing a surface that minimizes such risks while maintaining ease of movement is critical. Moreover, the expertise in engineering aluminium bar grating ensures that it meets strict safety and performance standards. Each piece can be customized with precise dimensions and grating patterns to fit specific structural requirements. Certification from recognized safety standards institutions further enhances the trustworthiness and authority of aluminium grating product offerings, making it a reliable choice for engineers and architects. Aluminium bar grating also offers aesthetic flexibility, with the ability to be finished in various coatings or left in its pristine form, depending on the project’s needs. This adaptability makes it a preferred choice not only for industrial applications but also in areas visible to the public, where visual appeal complements functionality. In an industry where practical experience and technical expertise are weighted heavily, aluminium bar grating continues to assert its prominence through tangible benefits and proven performance records. Its combination of strength, corrosion resistance, recyclability, and safety features aligns well with modern engineering requirements and sustainability goals, setting a benchmark for industrial flooring solutions. As industries evolve and new challenges arise, aluminium bar grating remains a competent solution, combining experience, expertise, authoritativeness, and trustworthiness into one versatile material.

Load distribution and safety are other key considerations where aluminium bar grating excels. The flat, serrated surface of the grating provides excellent traction even in wet or oily conditions, thereby reducing slip and fall risks. For industrial facilities where worker safety is paramount, choosing a surface that minimizes such risks while maintaining ease of movement is critical. Moreover, the expertise in engineering aluminium bar grating ensures that it meets strict safety and performance standards. Each piece can be customized with precise dimensions and grating patterns to fit specific structural requirements. Certification from recognized safety standards institutions further enhances the trustworthiness and authority of aluminium grating product offerings, making it a reliable choice for engineers and architects. Aluminium bar grating also offers aesthetic flexibility, with the ability to be finished in various coatings or left in its pristine form, depending on the project’s needs. This adaptability makes it a preferred choice not only for industrial applications but also in areas visible to the public, where visual appeal complements functionality. In an industry where practical experience and technical expertise are weighted heavily, aluminium bar grating continues to assert its prominence through tangible benefits and proven performance records. Its combination of strength, corrosion resistance, recyclability, and safety features aligns well with modern engineering requirements and sustainability goals, setting a benchmark for industrial flooring solutions. As industries evolve and new challenges arise, aluminium bar grating remains a competent solution, combining experience, expertise, authoritativeness, and trustworthiness into one versatile material.

Share

Prev:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025