- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

High-Quality Grating Galvanized Solutions Serrated, Catwalk & Bar Grating Supplier

- Introduction to grating galvanized

: characteristics and market overview - Technical advantages of serrated galvanized grating and galvanized catwalk grating

- Manufacturer comparison: evaluating quality, pricing, and service

- Customization options and design flexibility in galvanized bar grating

- Real-world application examples: data-driven insights

- Industry standards, certifications, and quality assurance

- Conclusion: Elevating projects with grating galvanized solutions

(grating galvanized)

Introduction to Grating Galvanized: Characteristics and Market Overview

Grating galvanized is a widely adopted structural product in the construction and industrial sectors, valued for its corrosion resistance, load-bearing capacity, and cost-effectiveness. As of 2023, the global galvanized steel grating market size surpassed USD 4 billion, experiencing a compound annual growth rate (CAGR) of 6.2%. Emerging trends include expanded use in infrastructure, transportation, and energy facilities due to its durability and reduced maintenance requirements.

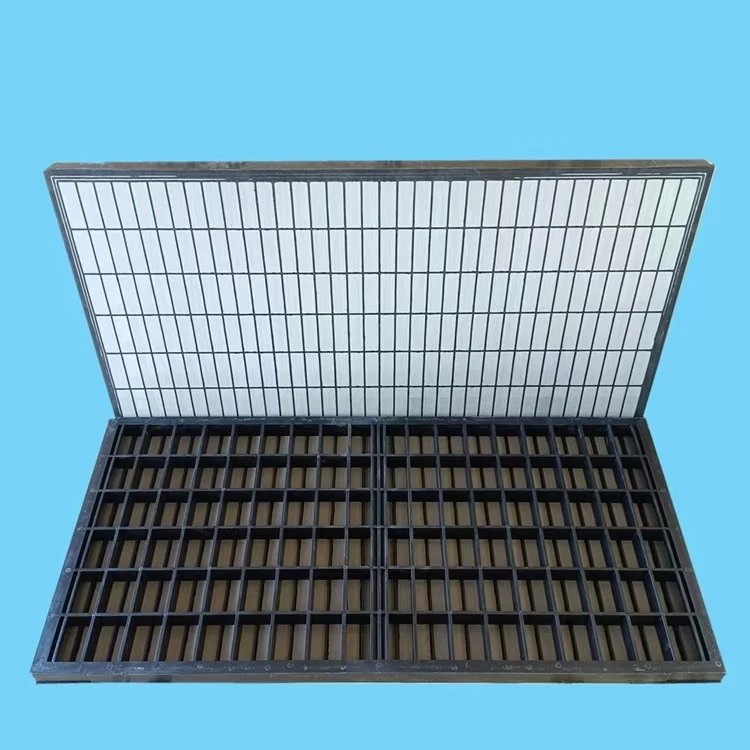

The galvanization process, which involves coating steel with a layer of zinc, enhances the product’s lifespan by preventing rust and degradation. Critical applications range from walkways and flooring to catwalks and drainage covers. Increased investments in public infrastructure and industrial projects have fueled demand, with Serrated Galvanized Grating and Galvanized Catwalk Grating gaining notable traction for their safety and reliability. Such products offer a blend of strength, resilience, and versatility that aligns with modern project requirements.

Technical Advantages of Serrated and Catwalk Galvanized Grating

The technical superiority of serrated galvanized grating and galvanized catwalk grating is anchored in their advanced fabrication and structural engineering principles. Serrated surfaces provide enhanced slip resistance, significantly reducing the risk of workplace accidents—even when exposed to oil, water, or other contaminants.

Galvanized catwalk grating features high-load bearing bars joined by cross rods, delivering exceptional rigidity and stability. Laboratory tests reveal that such grating can withstand distributed loads exceeding 7,000 lbs per square foot. The galvanized coating delivers extra resistance, with a typical zinc layer thickness of 85-100 microns, extending the material's service life by up to 50 years in non-aggressive environments.

Further, galvanized bar grating offers ease of installation, flexible panel configurations, and compatibility with modular architectural designs, optimizing project scheduling and reducing labor costs.

Manufacturer Comparison: Evaluating Quality, Pricing, and Service

Choosing the right grating supplier involves analyzing multiple critical parameters such as pricing, quality standards, lead times, and after-sales support. Leading international manufacturers, including AMICO, Ohio Gratings, and Ningbo Jiulong, compete in quality certifications, production capacity, and custom engineering capabilities. The comparison table below outlines key metrics:

| Manufacturer | Certifications | Min. Order (sqm) | Typical Lead Time | Warranty | Average Price (USD/sqm) | Customization |

|---|---|---|---|---|---|---|

| AMICO | ISO 9001, ASTM A123 | 20 | 4 weeks | 3 years | 72-85 | Available |

| Ohio Gratings | ISO 14001, ASTM A36 | 50 | 6 weeks | 5 years | 78-92 | Available |

| Ningbo Jiulong | CE, SGS | 10 | 3 weeks | 2 years | 60-74 | Available |

As the table shows, Asian suppliers often offer competitive pricing and shorter lead times, while North American manufacturers excel in extended warranties and stringent compliance with local standards. Users should consider their project’s geographic location, complexity, and timeline when selecting partners.

Customization Options and Design Flexibility in Galvanized Bar Grating

One of the principal strengths of galvanized bar grating lies in its adaptability to unique project requirements. Clients can specify bar spacing, thickness, cross-rod type, length, and width based on targeted load capacity and environmental conditions.

For instance, custom serrated profiles are available for sites with high foot traffic, oil exposure, or steep inclines, bolstering safety. Galvanized catwalk grating designs may include toe plates, kick plates, or custom edge banding to ensure compliance with specific safety codes.

Modular panel systems can be engineered to fit irregular layouts or retrofitted into existing infrastructure, with CAD-based fabrication minimizing dimensional variances to less than ±2 mm. Grating finishes can also be selected between hot-dip galvanization and electro-galvanization, depending on budget and exposure levels.

Manufacturers further enable end-users to personalize branding, incorporate anti-vibration dampers, or introduce integrated fastening solutions, facilitating seamless project execution from fabrication to installation.

Real-World Application Examples: Data-Driven Insights

The versatility of grating galvanized products is reflected in their diverse deployment across sectors. For instance, a 2022 petrochemical facility in Saudi Arabia utilized 20,000 sqm of serrated galvanized grating for maintenance walkways, with post-installation reports indicating a 47% reduction in slip incidents compared to previous flooring.

In the transportation sector, galvanized catwalk grating was selected for a major Brazilian railway bridge, handling static loads exceeding 10,000 lbs and withstanding harsh coastal humidity without signs of corrosion over a 5-year period. Likewise, municipal wastewater facilities in Germany installed galvanized bar grating for drainage covers, achieving annual maintenance savings of USD 120,000 due to lower repair frequency.

Such case studies underscore the importance of appropriate material selection and precise customization, as data consistently demonstrates improvements in safety, durability, and cost-efficiency.

Industry Standards, Certifications, and Quality Assurance

Stringent adherence to industry standards is pivotal for ensuring the reliability of galvanized grating systems. International benchmarks, including ASTM A123 (zinc coating processes), ISO 9001 (quality management), and EN 1090 (structural components), govern material selection, fabrication, and surface treatments.

Manufacturers employ laboratory testing—such as salt spray testing, load deflection testing, and dimensional analysis—to validate that galvanized bar grating meets or exceeds specified requirements. Suppliers may also provide traceability documentation, mill certificates, and third-party inspection reports upon request.

The table below summarizes the most critical standards and testing protocols:

| Standard | Testing Method | |

|---|---|---|

| ASTM A123 | Hot-dip zinc coating on iron/steel products | Coating thickness, adhesion, visual checks |

| ISO 1461 | Requirements for galvanization of fabricated iron/steel | Salt spray, thickness measurement |

| EN 1090 | Execution of steel structures and components | Mechanical load, dimensional evaluation |

Compliance ensures consistent product quality and guarantees that the grating system performs reliably throughout its expected service life, safeguarding both people and assets in demanding applications.

Conclusion: Elevating Projects with Grating Galvanized Solutions

Embracing grating galvanized as a core material delivers a strategic advantage in modern infrastructure and industrial projects. The synthesis of technical innovation, proven safety records, robust lifecycle cost savings, and responsive customization elevates both functionality and aesthetic appeal. As demonstrated by comparative manufacturer data, project-specific customization, and real-world performance, grating galvanized consistently outperforms alternatives in diverse environments.

With adherence to rigorous quality standards and the ability to tailor products to exact needs, stakeholders can confidently specify serrated galvanized grating, galvanized catwalk grating, or galvanized bar grating to optimize performance and value.

By selecting reputable suppliers and leveraging advanced engineering, projects can achieve superior safety, decreased maintenance liabilities, and long-term operational efficiency—securing a firm foundation for sustainable growth and innovation.

(grating galvanized)

FAQS on grating galvanized

Q: What is grating galvanized and why is it used?

A: Grating galvanized refers to steel grating that has been coated with a layer of zinc for corrosion protection. It is widely used for flooring, walkways, and platforms in industrial environments. The galvanization process ensures durability and a longer service life.

Q: What are the advantages of serrated galvanized grating?

A: Serrated galvanized grating has a toothed surface that provides excellent slip resistance. The galvanized layer also prevents rust and ensures longevity. This makes it ideal for areas where safety and durability are priorities.

Q: Where is galvanized catwalk grating commonly installed?

A: Galvanized catwalk grating is often used in industrial plants, factories, and workshops for elevated walkways. Its strength and anti-corrosion properties make it suitable for both indoor and outdoor catwalks. Installation is straightforward due to its modular design.

Q: How is galvanized bar grating different from regular steel grating?

A: Galvanized bar grating includes a zinc coating that protects against corrosion, unlike regular steel grating. It is designed for superior durability in harsh environments. This makes it preferable for applications requiring resilience and low maintenance.

Q: How is grating galvanized maintained after installation?

A: Grating galvanized requires minimal maintenance due to its protective zinc coating. Regular cleaning and inspection for physical damage are recommended. This helps ensure its maximum lifespan and performance in any application.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025