- ਉਦਯੋਗਿਕ ਜ਼ੋਨ, ਐਨਪਿੰਗ ਟਾਊਨ ਦੇ ਦੱਖਣ, ਹੇਂਗਸ਼ੂਈ, ਹੇਬੇਈ, ਚੀਨ।

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  ਅੰਗਰੇਜ਼ੀ

ਅੰਗਰੇਜ਼ੀ  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- ਅੰਗਰੇਜ਼ੀ

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Does Safety Net Mean in the Modern Construction World

In today’s dynamic industrial and construction landscape, the term safety net goes far beyond its literal meaning. So, what does safety net mean in this context? A safety net refers to a critical protective system installed at construction sites, factories, stadiums, or any elevated work zone to prevent falls and minimize injuries from dropped tools or materials. It acts as a security barrier between dangerous work heights and ground-level operations, shielding workers and bystanders alike.

The evolution of the safety net has mirrored advancements in building heights and worksite complexity. In the past, rudimentary rope nets provided some protection, but modern safety nets are constructed from high-strength synthetic fibers like nylon or polyethylene. They are UV-resistant, impact-absorbing, and designed to meet stringent international safety regulations. When deployed correctly, these nets can reduce fall-related fatalities and property damage dramatically.

The broader definition of a safety net also encompasses the concept of a contingency mechanism. Just as in social policy a safety net catches people in times of crisis, in construction a safety net ensures that accidents do not spiral into disasters. Whether it is installed below scaffolding or at the edges of multi-story buildings, it gives workers the confidence to focus and perform without fear. Understanding what does safety net mean is the first step toward appreciating its life-saving role in modern infrastructure.

The Vital Role of Perimeter Safety Net in Construction and Industry

A perimeter safety net is a specific type of safety net designed for horizontal and vertical installation along the edges of high-rise buildings, scaffolding, bridges, and towers. Unlike central nets or individual fall-arrest systems, a perimeter safety net functions to secure the entire boundary of a work platform or open structure, offering collective fall protection. This makes it one of the most efficient and scalable safety solutions for large projects.

These nets are typically made of high-tenacity polypropylene or polyethylene, featuring reinforced borders and UV-stabilized mesh patterns. A high-quality perimeter safety net will conform to international safety norms like EN 1263-1 and OSHA guidelines, ensuring resistance to tearing, degradation, and excessive deflection upon impact. Their bright colors, such as green or blue, improve visibility for site supervisors and safety auditors.

What makes a perimeter safety net especially vital is its dual function: it not only prevents workers from falling, but also catches tools, debris, or materials that could harm workers or pedestrians below. It promotes a cleaner and safer site by limiting object falls, which are one of the top five causes of jobsite injuries.

Additionally, the installation of a perimeter safety net is cost-effective and time-saving. It requires minimal maintenance and can be repositioned or reused for different job phases. When used alongside guardrails and personal protective equipment, it becomes a powerful component of an integrated safety system. Its presence on a construction site also improves compliance with regulatory audits and can lead to insurance savings for contractors and developers.

Understanding the Design and Performance of Perimeter Safety Netting

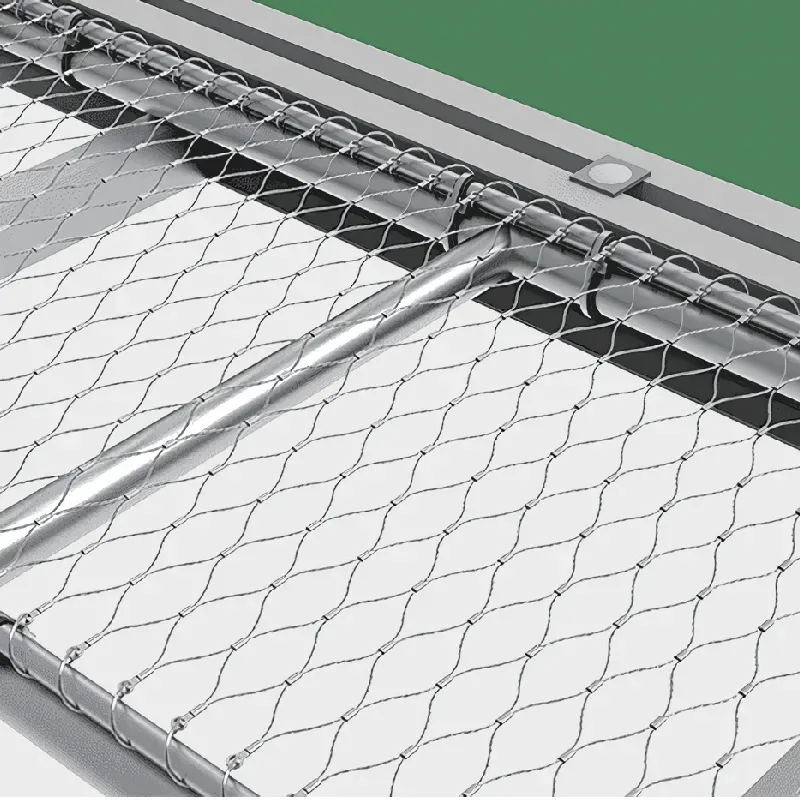

ਘੇਰੇ ਸੁਰੱਖਿਆ ਜਾਲ is not just any mesh. It is the result of years of engineering, materials science, and field testing. The performance of perimeter safety netting is defined by its mesh structure, material strength, and anchoring configuration. The netting can be knotted or knotless; the latter offering better shock absorption and reduced wear over time.

The load capacity of perimeter safety netting is a crucial metric. Quality netting can withstand impacts of up to 100 kg dropped from several meters without tearing or detaching. The mesh opening size is also regulated to prevent small tools and materials from slipping through. Nets are typically available in 60mm or 100mm meshes depending on the safety requirements of the site.

Installation systems vary: some nets are attached to rigid steel frames, others use rope lacing or snap hooks for flexibility. Proper tensioning and anchor placement are critical, and trained professionals should carry out both the setup and periodic inspections. Many perimeter safety netting products come with built-in fall indicators—visible strips that break when the net has been impacted, showing whether it’s safe to reuse or needs replacement.

Modern innovations in perimeter safety netting include flame-retardant coatings, anti-abrasion treatments, and modular net systems that can be deployed quickly on site. Manufacturers now offer customizable netting sizes to suit unique architectural shapes and industrial scaffolding setups. When selected wisely, perimeter safety netting becomes more than a legal requirement—it becomes a cornerstone of operational safety culture.

How Safety Net Systems Transform Worksite Productivity and Protection

Implementing a well-structured safety net system doesn’t just prevent injuries; it fundamentally transforms how projects operate. Teams can work more efficiently when they know that a safety net is in place to protect against falls or falling objects. This mental assurance leads to higher productivity, especially in tasks conducted at height, such as steel erection, roofing, or window installation.

Furthermore, a visible safety net system demonstrates a company’s commitment to worker welfare, which can improve morale and retention. Workers are more likely to perform carefully and confidently in environments that prioritize their wellbeing. This has a knock-on effect on project quality, timelines, and cost efficiency.

Legal compliance is another area where safety nets play a vital role. Occupational safety regulators across the globe mandate the use of fall protection systems for work conducted above certain heights. By investing in perimeter safety net systems, companies avoid penalties, litigation, and shutdowns due to non-compliance. They also reduce their workers’ compensation liabilities and insurance premiums.

Technological integration has further improved the usability of safety nets. Today, some systems come with IoT sensors to monitor tension, impact load, and net wear in real-time. These innovations enable predictive maintenance and minimize the risk of net failure. A smart safety net system offers peace of mind to project managers and safety officers alike.

Choosing the Right Partner for Perimeter Safety Netting Solutions

Selecting a reliable vendor for your perimeter safety net and perimeter safety netting needs is as crucial as the product itself. The best suppliers offer not only high-quality nets but also design consultation, on-site installation training, and compliance documentation. They work with you to assess load calculations, fall zones, and anchoring strategies based on your building or site layout.

Reputation and certifications matter. Look for companies whose safety net products are certified to EN or ASTM standards and whose manufacturing processes follow ISO guidelines. Experience in handling large, complex projects is also a significant advantage. Reliable vendors provide post-sale support, offer maintenance services, and can dispatch replacement nets quickly if needed.

Another key aspect is customization. A good perimeter safety netting provider should be able to tailor mesh size, net dimensions, and color coding to your unique requirements. Some also offer branding options so your safety net becomes part of your site identity, helping to promote your company’s image as one that prioritizes safety and quality.

In summary, the right partner will not only deliver strong, durable, and compliant nets—they’ll support you throughout the life cycle of your project, from planning and installation to inspection and beyond. In the business of safety, long-term relationships built on trust and performance are invaluable.

perimeter safety netting FAQs

What does safety net mean in construction?

In construction, a safety net is a protective system installed at height to catch falling workers or materials. It provides collective protection across large areas, helping to reduce fall-related accidents and promote a safer work environment.

How is perimeter safety net different from regular safety netting?

A perimeter safety net is specifically designed to be installed around the edges of buildings, scaffolds, or elevated platforms. It offers horizontal protection at the site perimeter, whereas general safety netting may cover broader or more customized zones.

Is perimeter safety netting reusable?

Yes, high-quality perimeter safety netting can be reused if it hasn’t sustained damage. However, after any significant impact, the net should be inspected by qualified personnel. Many nets come with fall indicators to visually signal whether they’ve been compromised.

What materials are commonly used in safety nets?

Modern safety nets are typically made from high-tenacity polypropylene or polyethylene, offering strong tensile resistance, weather durability, and UV protection. These materials are lightweight yet robust, making them ideal for demanding outdoor environments.

Are safety nets legally required on construction sites?

Yes, in most regions, occupational safety laws mandate the use of safety nets or equivalent fall protection systems when working at height. Regulations vary, but compliance is essential to avoid penalties, ensure worker safety, and maintain insurance coverage.

-

Unlocking Efficiency with Premium Shaker Screensਖ਼ਬਰਾਂAug.05,2025

-

Safety and Style with Metal Grate Walkwayਖ਼ਬਰਾਂAug.05,2025

-

Optimize Operations with Shaker Screen Solutionsਖ਼ਬਰਾਂAug.05,2025

-

Enhance Your Space with Steel Gratingਖ਼ਬਰਾਂAug.05,2025

-

Durability with Concrete Weight Coating Meshਖ਼ਬਰਾਂAug.05,2025

-

Discover the Power of Perimeter Safety Netਖ਼ਬਰਾਂAug.05,2025