- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Feb . 16, 2025 04:48

Back to list

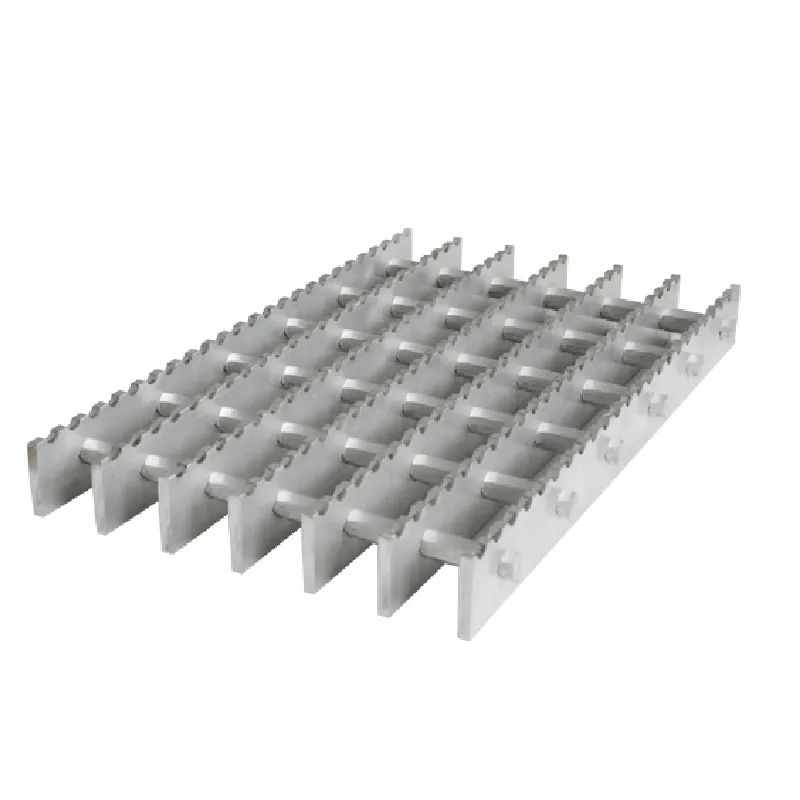

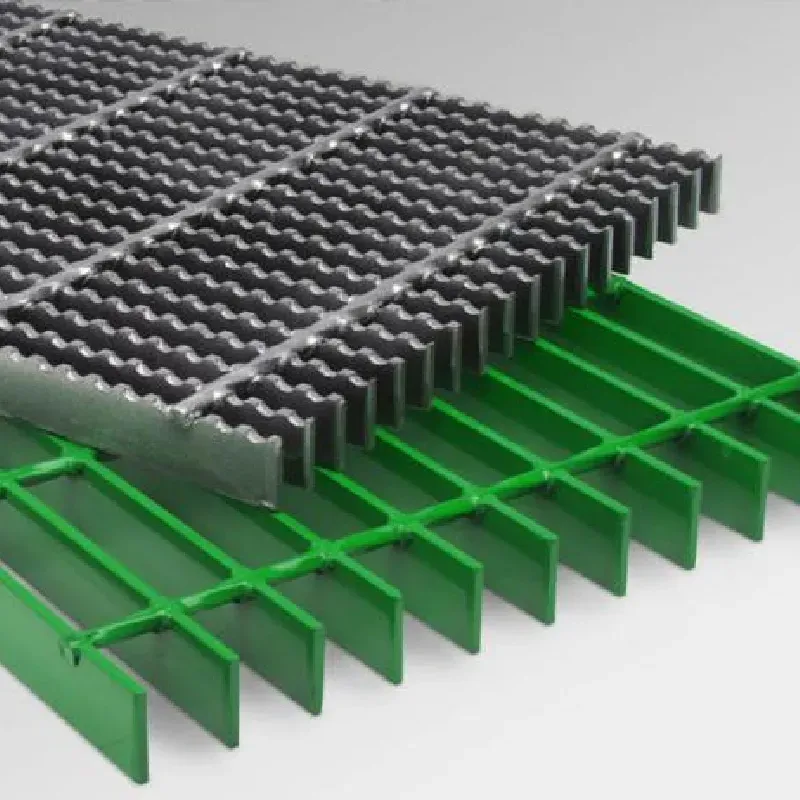

galvanized drainage grates

Galvanized drainage grates are an essential component in the effective management of surface water, particularly in urban and industrial environments. These grates are prized not only for their durability and strength but also for their ability to withstand harsh weather conditions and heavy vehicular loads. Understanding the advantages and applications of galvanized drainage grates will enhance the management of your drainage system and ultimately protect infrastructure investments.

Trustworthiness in the context of galvanized drainage grates is established through numerous case studies and user testimonials that demonstrate their efficacy in real-world applications. For instance, urban planners in coastal cities have successfully utilized these grates to combat the effects of saltwater corrosion, a common challenge in such environments. Additionally, industrial complexes that experience regular heavy vehicular traffic have found these grates to be resilient, maintaining structural integrity without bending or breaking. From a product perspective, galvanized drainage grates are available in a variety of sizes and load ratings to suit different applications, from sidewalks and pedestrian areas to industrial roads and airport runways. Their versatility ensures that they can be integrated seamlessly into virtually any existing drainage system without compromising on performance or aesthetics. The process of choosing the right galvanized drainage grate involves considering factors such as load rating, grate spacing to prevent debris blockage, and the specific environmental conditions they will be exposed to. Consulting with a professional engineer or a drainage system specialist can provide tailored recommendations that match project specifications and local regulatory requirements. In conclusion, galvanized drainage grates offer a combination of durability, cost efficiency, regulatory compliance, and adaptability, making them an ideal choice for modern drainage solutions. Their reliability in diverse settings has made them a preferred product among professionals aiming to implement long-lasting and effective drainage strategies. Leveraging their capabilities can result in safer, more robust infrastructure that not only meets but exceeds standard performance expectations.

Trustworthiness in the context of galvanized drainage grates is established through numerous case studies and user testimonials that demonstrate their efficacy in real-world applications. For instance, urban planners in coastal cities have successfully utilized these grates to combat the effects of saltwater corrosion, a common challenge in such environments. Additionally, industrial complexes that experience regular heavy vehicular traffic have found these grates to be resilient, maintaining structural integrity without bending or breaking. From a product perspective, galvanized drainage grates are available in a variety of sizes and load ratings to suit different applications, from sidewalks and pedestrian areas to industrial roads and airport runways. Their versatility ensures that they can be integrated seamlessly into virtually any existing drainage system without compromising on performance or aesthetics. The process of choosing the right galvanized drainage grate involves considering factors such as load rating, grate spacing to prevent debris blockage, and the specific environmental conditions they will be exposed to. Consulting with a professional engineer or a drainage system specialist can provide tailored recommendations that match project specifications and local regulatory requirements. In conclusion, galvanized drainage grates offer a combination of durability, cost efficiency, regulatory compliance, and adaptability, making them an ideal choice for modern drainage solutions. Their reliability in diverse settings has made them a preferred product among professionals aiming to implement long-lasting and effective drainage strategies. Leveraging their capabilities can result in safer, more robust infrastructure that not only meets but exceeds standard performance expectations.

Share

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025