- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

5 Inch Trench Drain Grates for Effective Water Management Solutions

Understanding 5% Trench Drain Grates Importance, Types, and Installation

In modern landscaping and construction, effective water management is crucial to preserve structural integrity and enhance aesthetic appeal. One essential component used in this framework is the trench drain, often equipped with grates. Among various specifications, the 5% trench drain grates have gained attention for their unique qualities and advantages. In this article, we will explore what trench drain grates are, the significance of the 5% specification, the different types of grates available, and guidelines for their installation.

What Are Trench Drain Grates?

Trench drain grates are covers that sit on top of drainage channels or systems designed to manage surface water runoff. These systems are often found in environments prone to flooding, such as driveways, parking lots, and sports fields. The primary role of these grates is to allow water to enter the drainage system while preventing debris and larger objects from clogging the channel.

The Importance of the 5% Specification

The term 5% often refers to the open area of the drain grate, which can indicate the percentage of the surface area that is open for water to flow through. A 5% trench drain grate allows for efficient water flow without compromising structural integrity. This is especially beneficial in areas where heavy rain or sudden storms can lead to pooling water, which may cause localized flooding or erosion.

A grate with a 5% opening ratio balances durability and functionality. It provides sufficient surface area for water passage while maintaining enough material for strength, ensuring the structure can withstand vehicular traffic or pedestrian use without warping or breaking.

Types of Trench Drain Grates

1. Material Types - Metal Grates Commonly made from cast iron, steel, or aluminum, these grates offer durability and resistance to wear from traffic. However, they may corrode if not treated properly. - Plastic Grates Often made from high-density polyethylene (HDPE), plastic grates are lightweight and resistant to chemicals. They are ideal for areas with less traffic. - Concrete Grates Concrete grates are extremely durable and are used in heavy-duty applications, such as industrial sites or roadways. However, they can be more challenging to install and replace.

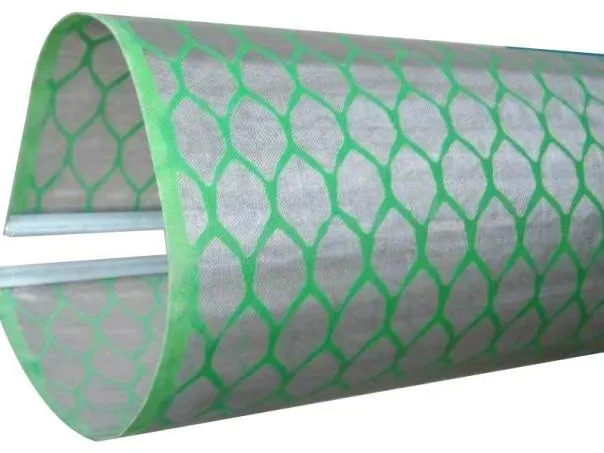

2. Design Configurations - Slotted Grates Featuring a series of long, narrow openings, slotted grates offer high flow rates, making them suitable for regions with heavy rainfall. - Mesh Grates These grates have a more extensive filtering capability, effectively blocking out debris, which is advantageous in areas with significant leaf litter or small debris. - Symmetrical and Asymmetrical Grates These designs are chosen based on the installation area; symmetrical grates provide a balanced look, while asymmetrical grates can enhance drainage efficiency in specific situations.

5 inch trench drain grates

Installation Guidelines

When installing 5% trench drain grates, proper preparation and technique are essential to ensure long-term efficiency and durability. Here are key steps to consider

1. Planning the Drainage Layout Start by assessing the area to determine the necessary drainage paths and the locations where trench drains should be installed. Consider slope and natural water flow to optimize efficiency. 2. Excavation Dig a trench that matches the dimensions of the drain channel and meets local regulations. The trench should have a slight slope (approximately 1-2% grade) to direct water flow toward the drainage outlet.

3. Installing the Drainage Channel Place the trench drain channel in the excavated trench. Ensure it is leveled and aligned correctly to promote efficient water flow.

4. Attaching the Grate Once the channel is securely in place, attach the 5% drain grate according to the manufacturer’s instructions. Use the appropriate fastening method to ensure the grate remains in position, especially in high-traffic areas.

5. Backfilling Fill around the drain with appropriate fill material to stabilize the structure, ensuring that water can still easily enter the channel.

6. Testing the System After installation, it’s essential to test the drain to confirm that water flows correctly, indicating that the system is functioning as intended.

Conclusion

5% trench drain grates play a vital role in effective water management in landscaping and construction. Their unique specifications and flexibility in design make them suitable for various environments. By understanding the types, importance, and installation techniques for these grates, property owners and landscape professionals can ensure that their drainage systems function optimally, protecting infrastructure and enhancing outdoor spaces.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025