- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Feb . 18, 2025 02:07

Back to list

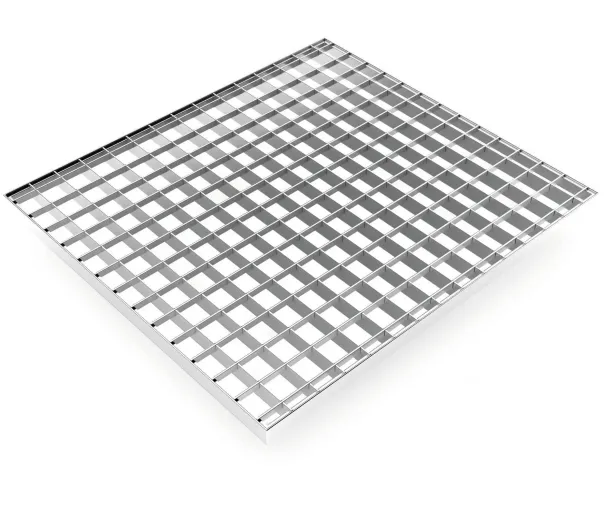

Steel Grating

Galvanized steel grating stands as a quintessential choice in the realm of industrial flooring and structural applications, blending durability with practicality. This material, revered for its anti-corrosive properties and robustness, is manufactured through a meticulous process of hot-dip galvanizing. This ensures a zinc coating that provides a barrier against harsh environmental elements, ultimately extending the lifespan of the steel beneath.

Trustworthiness is at the heart of why galvanized steel grating continues to be a preferred choice. Its anti-slip properties, essential for preventing workplace accidents, make it a staple in safety-first environments. Furthermore, the predictability of its performance over extended periods minimizes the need for frequent replacements, yielding long-term cost benefits. Project success stories repeatedly highlight the advantages of using galvanized steel grating. One notable instance involves a coastal manufacturing facility where constant exposure to salty air posed a substantial risk to unprotected metal structures. The transition to galvanized steel grating resulted in a dramatic reduction in maintenance costs and downtime associated with corrosion-related issues. In conclusion, galvanized steel grating remains an exemplary product in industrial and structural applications due to its exceptional blend of durability, safety features, and compliance with industry standards. Its widespread adoption across various sectors is a testament to its quality and reliability. As industries evolve and the demand for high-performing materials increases, galvanized steel grating continues to hold its place as a trusted, authoritative solution that meets and exceeds the expectations of engineers and industry professionals alike.

Trustworthiness is at the heart of why galvanized steel grating continues to be a preferred choice. Its anti-slip properties, essential for preventing workplace accidents, make it a staple in safety-first environments. Furthermore, the predictability of its performance over extended periods minimizes the need for frequent replacements, yielding long-term cost benefits. Project success stories repeatedly highlight the advantages of using galvanized steel grating. One notable instance involves a coastal manufacturing facility where constant exposure to salty air posed a substantial risk to unprotected metal structures. The transition to galvanized steel grating resulted in a dramatic reduction in maintenance costs and downtime associated with corrosion-related issues. In conclusion, galvanized steel grating remains an exemplary product in industrial and structural applications due to its exceptional blend of durability, safety features, and compliance with industry standards. Its widespread adoption across various sectors is a testament to its quality and reliability. As industries evolve and the demand for high-performing materials increases, galvanized steel grating continues to hold its place as a trusted, authoritative solution that meets and exceeds the expectations of engineers and industry professionals alike.

Share

Prev:

Next:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025