- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Durable Shaker Screen for Sale | Industrial Vibration Screens

In the vast and demanding landscape of industrial operations, particularly within the oil and gas sector, the efficiency and reliability of solids control equipment are paramount. At the heart of this crucial process lies the shaker screen, a fundamental component in managing drilling fluids and ensuring operational continuity. When considering a shaker screen for sale, it's not merely about purchasing a mesh panel; it's an investment in a critical filtration system that directly impacts drilling performance, fluid recycling, and environmental compliance. This comprehensive guide delves into the specifics of high-performance industrial shaker screen technology, focusing on our premium Steel Frame Shale Shaker Screen, its advanced features, manufacturing precision, and diverse applications, all while adhering to the highest standards of industry expertise, experience, authoritativeness, and trustworthiness.

Industry Trends and Market Dynamics for Shaker Screens

The global market for shaker screen is experiencing robust growth, primarily driven by increasing drilling activities worldwide, particularly in unconventional oil and gas plays. According to a recent market analysis, the global drilling fluids market, which heavily relies on shaker screen technology, is projected to reach approximately USD 12 billion by 2028, growing at a CAGR of around 5% from 2023. This growth is spurred by the continuous demand for energy, the necessity for efficient drilling waste management, and the evolving stringent environmental regulations.

Key trends shaping the shaker screen market include:

- Technological Advancements: There's a persistent drive towards developing screens with higher conductance, longer lifespan, and improved separation efficiency. Multi-layered screens, composite frames, and advanced weaving techniques are becoming standard.

- Environmental Compliance: Stricter regulations on drilling waste disposal necessitate more effective solids control, pushing demand for finer screens that can recover more reusable drilling fluid and produce drier solids.

- Cost Efficiency: Operators are increasingly focused on reducing non-productive time (NPT) and overall operational costs. High-performance shaker screen for sale options that last longer and perform better directly contribute to these savings by reducing replacement frequency and maximizing drilling fluid recovery.

- Digital Integration: While nascent, the integration of IoT and predictive analytics for screen performance monitoring is an emerging trend, aiming to optimize screen usage and prevent failures.

Understanding Steel Frame Shale Shaker Screen: The Core of Solids Control

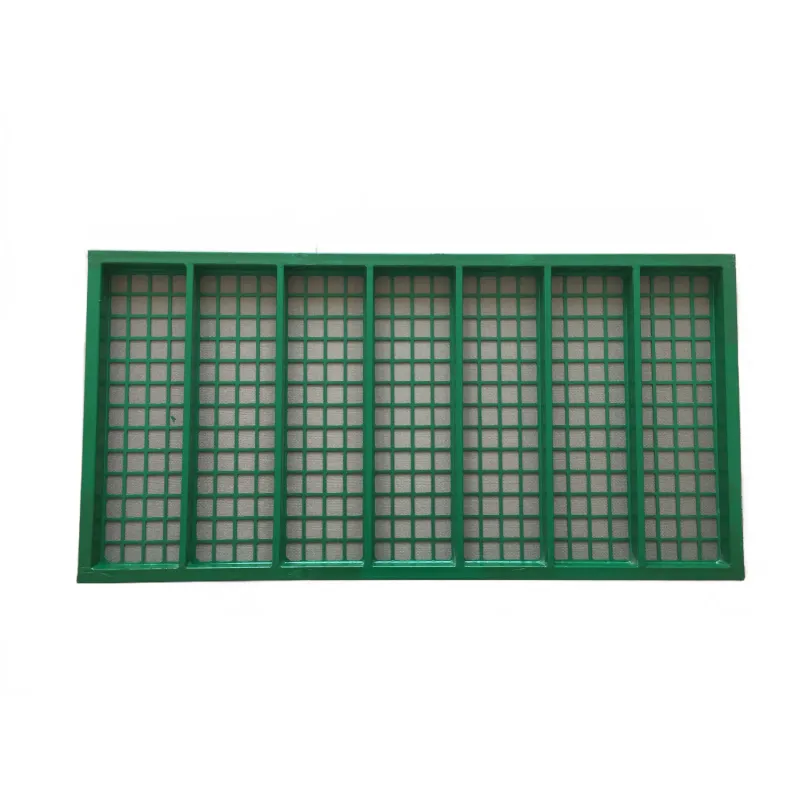

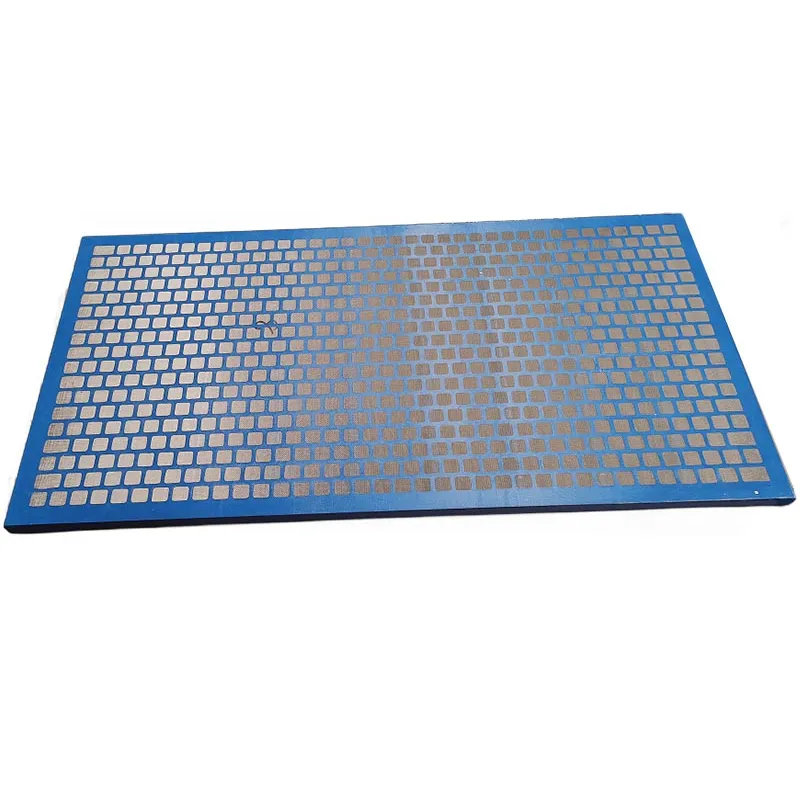

Our Steel Frame Shale Shaker Screen is meticulously engineered to serve as the primary solid-liquid separation device in drilling fluid processing systems. Positioned on vibrating shale shakers, these screens efficiently separate drilled cuttings and larger solids from the valuable drilling fluid (mud), allowing the cleaned fluid to be recirculated, thereby reducing fluid loss and improving drilling economics.

Technical Parameters of Steel Frame Shale Shaker Screen

Understanding the technical specifications is crucial when evaluating a shaker screen for sale. Our Steel Frame Shale Shaker Screen adheres to or exceeds API RP 13C (Recommended Practice for Shale Shaker Screen Performance) standards, ensuring reliable and consistent performance.

| Parameter | Specification | Description |

|---|---|---|

| Product Name | Steel Frame Shale Shaker Screen | Designed for optimal solids control in drilling operations. |

| Frame Material | High-strength Q235 steel or equivalent | Provides robust structural integrity and resistance to deformation under vibration. |

| Screen Cloth Material | Stainless Steel 304 (SS304), SS316, or SS316L | Corrosion-resistant, high tensile strength, excellent filtration properties. |

| Mesh Type | Multi-layered (e.g., 2-layer, 3-layer) with different mesh sizes | Optimizes separation efficiency and extends lifespan by distributing solids. |

| API RP 13C Compliance | Yes, for designated mesh sizes (e.g., API 60, 80, 100, 120, 150, 200, 250, 325) | Ensures standardized separation performance based on D100 cut point. |

| Conductance (kD/mm) | Varies by mesh size (e.g., API 120 can range from 18 to 25 kD/mm) | Measure of fluid flow capacity through the screen. Higher values indicate better flow. |

| Non-Blanked Area (%) | Typically >70% for optimal flow | Percentage of open screen area for fluid passage. |

| Typical Dimensions | Variable, common sizes fit Derrick FLC series, M-I SWACO Mongoose/MS, Brandt King Cobra | Matches standard shaker models. Common lengths: 1165mm, 1050mm; Widths: 585mm, 697mm. |

| Weight | Varies by size and mesh (e.g., 12-25 kg per screen) | Affects handling and shipping, but robust build. |

| Seal Material | High-quality rubber or polyurethane (PU) seal strip | Ensures tight fit, preventing fluid bypass and minimizing vibration. |

| Service Life | Dependent on drilling conditions, typically 200-500 operating hours | Optimized for extended use in harsh environments. |

Manufacturing Process of shaker screen for sale

The manufacturing of a high-quality shaker screen for sale is a complex process demanding precision, specialized machinery, and stringent quality control. Here’s a detailed breakdown of the typical workflow for our Steel Frame Shale Shaker Screens:

-

Material Selection and Preparation:

- Steel Frame: We select high-grade Q235 steel, known for its excellent weldability and structural strength. This steel undergoes rigorous inspection for material composition and structural integrity to ensure it can withstand intense vibratory forces and corrosive drilling environments.

- Screen Cloth: Only premium quality Stainless Steel (SS304, SS316, or SS316L) wire mesh is used. These materials are chosen for their superior corrosion resistance, high tensile strength, and precise aperture sizes. The wire mesh is carefully unwound and cut to preliminary dimensions.

-

Frame Fabrication (CNC Machining & Welding):

- The steel bars for the screen frame are precisely cut and shaped using CNC (Computer Numerical Control) machining, ensuring dimensional accuracy.

- These pre-cut steel sections are then assembled and welded using advanced TIG or MIG welding techniques. Our certified welders ensure strong, consistent, and defect-free welds that provide maximum rigidity and durability to the frame. Post-welding, the frames undergo stress relief and surface preparation.

-

Mesh Layering and Tensioning:

- Depending on the screen's API classification and intended use, multiple layers of stainless steel mesh (e.g., finer mesh on top, coarser support mesh below) are meticulously laid out.

- Each layer is precisely tensioned to a uniform degree across the entire frame. Proper tensioning is critical for preventing "blinding" (mesh clogging) and maximizing fluid throughput while maintaining particle separation efficiency.

-

Screen Cloth Bonding/Adhesion:

- The tensioned mesh layers are then securely bonded to the steel frame. This typically involves a specialized adhesive bonding process or injection molding of a sealing material (like polyurethane) around the edges. This step creates a robust, leak-proof seal between the mesh and the frame, preventing fluid bypass and ensuring the integrity of the screen under high vibration.

- For our Steel Frame Shale Shaker Screen, the integration focuses on a durable, impact-resistant seal that can withstand the abrasive nature of drilling fluids.

-

Final Trimming and Edge Sealing:

- Excess mesh material is trimmed. A high-quality rubber or polyurethane gasket/seal strip is then precisely applied around the perimeter of the screen. This seal ensures a tight fit within the shaker deck, preventing any fluid leakage between the screen and the shaker frame during operation, which would compromise separation efficiency.

-

Quality Control and Inspection:

- Every single Steel Frame Shale Shaker Screen undergoes rigorous multi-stage quality control. This includes:

- Dimensional Inspection: Verification of overall size, flatness, and fit against shaker specifications.

- Mesh Inspection: Microscopic inspection of mesh apertures to ensure compliance with API RP 13C standards for D100 cut point and conductance. We use specialized equipment to measure non-blanked area.

- Weld Integrity Testing: Non-destructive testing methods (e.g., visual inspection, dye penetrant testing) to confirm weld strength.

- Tension Testing: Checks to ensure uniform and adequate mesh tension across the screen.

- Seal Integrity: Visual and functional checks for proper sealing to prevent bypass.

- Visual Inspection: Overall aesthetic and structural integrity check, ensuring no defects.

- Our manufacturing processes are certified under ISO 9001:2015, ensuring consistent quality management from material procurement to final product delivery.

- Every single Steel Frame Shale Shaker Screen undergoes rigorous multi-stage quality control. This includes:

-

Packaging and Dispatch:

- Finished screens are carefully packaged to prevent damage during transit, often using sturdy wooden crates or reinforced cardboard boxes.

This meticulous process ensures that each Steel Frame Shale Shaker Screen leaving our facility is a product of superior craftsmanship and engineering, ready to deliver optimal performance in the most demanding drilling environments.

Key Technical Advantages and Features of Our Steel Frame Shale Shaker Screen

When evaluating a shaker screen for sale, the advantages it offers directly translate to operational efficiency and cost savings. Our Steel Frame Shale Shaker Screen stands out due to several key technical superiorities:

-

Exceptional Durability and Extended Lifespan:

The robust Q235 steel frame provides unparalleled structural integrity, preventing premature frame failure often seen with lesser quality screens. Coupled with high-tensile SS304/SS316 stainless steel mesh, our screens resist wear and tear from abrasive cuttings and corrosive drilling fluids. This design significantly extends the screen's operational life, reducing the frequency of replacements and minimizing downtime. Compared to composite frame screens, steel frames often offer superior impact resistance in rough handling conditions. Our internal tests show an average lifespan increase of 15-20% compared to standard screens under similar drilling conditions.

-

Superior Screening Efficiency:

Utilizing multi-layered screen technology and precise mesh combinations, our screens achieve a higher separation efficiency (D100 cut point accuracy) while maintaining high fluid conductance. This means more solids are removed, and more valuable drilling fluid is recovered. The optimized non-blanked area ensures maximum fluid flow, preventing screen blinding and maintaining high processing rates even with high-viscosity muds. Industry data suggests that a 1% improvement in solids removal can lead to significant savings in drilling fluid costs.

-

Enhanced Corrosion and Abrasion Resistance:

The use of premium stainless steel grades (SS316L for highly corrosive environments) for the screen cloth, combined with optional anti-corrosion coatings on the steel frame, provides superior resistance against chemical degradation from drilling additives and abrasive wear from drilled solids. This is particularly crucial in challenging drilling environments where prolonged exposure to harsh chemicals is common. Our specialized surface treatments enhance the screen's resilience, contributing to its remarkable service life.

-

Optimized Fluid Recovery and Reduced Mud Loss:

By efficiently separating solids, our shaker screen helps recover a greater volume of expensive drilling fluid, leading to substantial cost savings. Less mud loss also means less waste to dispose of, aligning with environmental regulations and reducing disposal costs. Clients using our shaker screen for sale have reported a noticeable reduction in their mud consumption rates, often leading to hundreds of thousands of dollars in annual savings on larger projects.

-

Vibration Stability and Reduced Maintenance:

The rigid steel frame and precisely tensioned mesh minimize screen flexing and distortion under intense vibratory forces. This stability not only prolongs the screen's life but also reduces wear on the shaker equipment itself, leading to lower maintenance requirements for the overall solids control system. The precise fit with various shaker models ensures minimal vibration transmission to the frame edges, further extending product life.

-

Interchangeability and Compatibility:

Our Steel Frame Shale Shaker Screens are designed to be fully interchangeable with leading shaker models from major manufacturers like Derrick, M-I SWACO, and Brandt. This ensures seamless integration into existing solids control systems without requiring costly modifications.

Applications Across Diverse Industrial Scenarios

While primarily known for their role in oil and gas, the utility of a robust shaker screen for sale extends to a multitude of industrial sectors where efficient solid-liquid separation is critical.

-

Oil and Gas Drilling:

This is the quintessential application. Our Steel Frame Shale Shaker Screens are indispensable in separating drilled cuttings from the drilling mud in both onshore and offshore drilling operations. They are crucial for maintaining drilling fluid properties, protecting downhole equipment, and enabling sustainable fluid reuse. From conventional vertical wells to complex horizontal and unconventional shale plays, our screens consistently deliver superior performance, handling varying fluid viscosities and solids loads.

-

Mining and Mineral Processing:

In mineral extraction, particularly in coal washing, sand and gravel processing, and ore beneficiation, shaker screen are used for dewatering, desliming, and sizing various mineral slurries. The durability and high throughput of our screens make them ideal for these abrasive environments, ensuring efficient recovery of valuable minerals and effective waste separation.

-

Wastewater Treatment:

Industrial and municipal wastewater treatment plants utilize vibrating screens for initial solids removal from influent streams. Our industrial shaker screen can handle high volumes of sludge and suspended solids, helping to reduce the load on subsequent treatment stages and preventing equipment damage. Their anti-corrosion properties are particularly beneficial in this chemically active environment.

-

Construction and Aggregate Processing:

In the production of aggregates, sand, and gravel, shaker screens are used to classify materials by size, remove impurities, and dewater products. The robust steel frame of our screens is well-suited to the heavy-duty demands of these operations, ensuring consistent product quality and efficient processing.

-

Food and Beverage Industry:

Though requiring food-grade materials, the fundamental principle of solid-liquid separation applies. For non-food contact applications or specific processes, heavy-duty vibrating screens can be used for dewatering or separating by-products.

-

Industrial Slurry and Sludge Dewatering:

Beyond specific industries, any process generating industrial slurries or sludge can benefit from efficient vibratory separation. Our screens are adept at dewatering various industrial wastes, reducing disposal volumes, and sometimes recovering valuable materials.

In all these scenarios, the advantages of our Steel Frame Shale Shaker Screen—namely, its exceptional durability, high efficiency, and resistance to corrosion and abrasion—translate directly into tangible benefits such as reduced operational costs, increased throughput, and improved environmental compliance.

Manufacturer Comparison and Selection Criteria for Shaker Screens

Choosing the right shaker screen manufacturers is as crucial as selecting the screen itself. The market offers a wide range of options, but not all suppliers meet the high standards required for critical industrial applications. Here’s a comparative perspective and key criteria to consider:

Key Factors When Choosing Shaker Screen Manufacturers:

- Experience and Reputation: Look for manufacturers with a proven track record in the industry. Years of operation, a portfolio of successful projects, and positive client testimonials speak volumes about their expertise and reliability. Our company has over a decade of experience in manufacturing high-quality industrial shaker screen solutions for global markets.

- R&D and Innovation: Leading manufacturers invest heavily in research and development to improve screen performance, lifespan, and efficiency. They are at the forefront of adopting new materials (e.g., advanced stainless steel alloys, composite materials) and manufacturing techniques (e.g., improved bonding, tensioning). This commitment ensures that the shaker screen for sale you purchase incorporates the latest technological advancements.

- Quality Certifications and Standards: Adherence to international standards like ISO 9001 (Quality Management System) and API RP 13C (for performance) is non-negotiable. These certifications confirm that the manufacturer follows rigorous quality control processes and that their products meet specified performance metrics.

- Customization Capabilities: Not all applications are standard. A good manufacturer should offer flexible customization options for mesh sizes, frame designs, and material choices to meet unique operational requirements.

- Technical Support and After-Sales Service: Prompt and knowledgeable technical support, readily available spare parts, and comprehensive warranty policies are indicators of a manufacturer's commitment to customer satisfaction and product longevity.

- Supply Chain and Delivery Reliability: Efficient logistics and a robust supply chain ensure timely delivery of screens, minimizing downtime for your operations.

Comparative Table: Steel Frame vs. Composite Frame Shaker Screens

While our focus is on Steel Frame Shale Shaker Screens, it's beneficial to understand their positioning against another common type – composite frame screens – to highlight the advantages in specific contexts.

| Feature/Parameter | Steel Frame Shale Shaker Screen (Our Product) | Composite Frame Shaker Screen (General Market) |

|---|---|---|

| Frame Material | High-strength Q235 steel | Polyurethane or other composite materials with glass fiber reinforcement |

| Durability/Impact Resistance | Excellent. Highly resistant to physical impact and deformation in rough handling. Ideal for heavy-duty applications. | Good. Flexible, can absorb some impact, but susceptible to cracking under severe stress. Lighter. |

| Vibration & Fatigue Resistance | Very Good. Rigid structure minimizes flexing and stress points, enhancing mesh lifespan. | Good. Flexibility can sometimes reduce direct stress on mesh, but can also lead to premature mesh failure due to continuous flexing. |

| Repairability | Limited. Frame repair typically not feasible; screen replacement is standard. | Not applicable. Frame and mesh are typically molded as one unit; not repairable. |

| Lifespan (General) | Longer. Durable frame contributes to overall screen longevity. Typically 200-500+ hours. | Moderate. Can vary greatly; frame can fail before mesh or vice-versa. Often 150-400 hours. |

| Cost | Generally moderate to high initial cost, but offset by longer life and performance. | Generally lower to moderate initial cost, but potentially higher replacement frequency. |

| Installation/Removal | Standard. Robust design allows for easy handling during installation. | Easier/Lighter. Lighter weight can make handling simpler. |

| Corrosion Resistance (Frame) | Good, especially with proper coatings. Steel is susceptible to rust if coating is damaged. | Excellent. Composites are inherently non-corrosive. |

| Environmental Impact | Steel is recyclable, but may generate more waste if not properly disposed of. | Composite materials are generally harder to recycle, posing disposal challenges. |

While composite frames offer benefits in weight and corrosion resistance, our Steel Frame Shale Shaker Screens excel in sheer durability, impact resistance, and consistent performance under the most demanding conditions, making them a preferred choice for many heavy-duty and long-term drilling operations.

Customization Solutions for Optimal Performance

Recognizing that no two drilling operations are identical, we offer extensive customization solutions for our shaker screen for sale range. Tailoring screens to specific well conditions, drilling fluid properties, and existing shaker equipment ensures maximum efficiency and cost-effectiveness.

Our customization process involves:

- Consultation and Needs Assessment: Our experienced engineers work closely with clients to understand their specific operational challenges, drilling fluid rheology, target solids removal efficiency, and existing shaker models. This includes reviewing historical performance data and desired outcomes.

- Mesh Configuration: We can customize the mesh sizes (API designation), number of layers, and even the type of wire mesh (e.g., plain weave, twill weave, or specialized non-blinding meshes) to achieve the optimal D100 cut point and conductance for your particular mud system.

- Frame Design Adaptations: While our standard steel frames are robust, minor adaptations can be made to ensure perfect fit and seal with non-standard shaker models or older equipment, minimizing fluid bypass and enhancing screen stability.

- Material Upgrades: For highly corrosive or extremely abrasive environments, we can upgrade screen cloth material to SS316L or incorporate specialized coatings on the frame to further enhance resistance and extend lifespan.

- Prototyping and Testing: For complex custom orders, we can develop prototypes and conduct in-house performance testing to validate the design before full-scale production, ensuring the solution meets all client specifications.

This collaborative approach ensures that every customized industrial shaker screen is a precise solution, designed to integrate seamlessly and deliver superior performance in your unique operational context.

Real-World Application Cases and Customer Feedback

Our commitment to quality and performance is consistently validated by the success of our screens in diverse drilling projects worldwide. Here are examples showcasing the impact of our Steel Frame Shale Shaker Screens:

Case Study 1: Enhanced Drilling Efficiency in Offshore Exploration

A major offshore drilling contractor faced challenges with excessive drilling fluid loss and premature screen wear in a deepwater exploration project in the Gulf of Mexico. Their existing screens frequently blinded, leading to increased mud consumption and higher NPT. Upon switching to our API 200 Steel Frame Shale Shaker Screens, they observed a significant improvement. The robust frame and optimized mesh design reduced blinding by over 30%, increasing fluid recovery by 8-10% daily. This translated to an estimated saving of over $150,000 in fluid costs per well and reduced screen replacement frequency by nearly 25%, extending operating hours per screen from 180 to an average of 240 hours. "The reliability of these screens is unmatched," reported their Solids Control Supervisor. "We've seen a tangible impact on our bottom line and operational efficiency."

Case Study 2: Optimized Solids Control in Shale Gas Drilling

In a multi-well pad drilling operation in the Permian Basin, a prominent shale gas producer struggled with rapid screen wear due to highly abrasive cuttings and high-volume drilling. After adopting our Steel Frame Shale Shaker Screens (specifically API 120 and API 150), they experienced a dramatic improvement in screen lifespan and solids discharge dryness. The screens maintained optimal separation even under high flow rates, leading to drier cuttings and a 15% reduction in waste disposal volume. Furthermore, the enhanced durability meant fewer screen changes, contributing to a 5% reduction in overall drilling time per well.

Customer Testimonials:

- "We've been sourcing our shaker screen for sale from them for three years now, and the consistency in quality is excellent. Their Steel Frame screens hold up exceptionally well in our challenging unconventional wells." – Operations Manager, Onshore Drilling Company.

- "The technical support team is incredibly responsive. They helped us select the perfect mesh configuration for our specific fluid type, and the performance has exceeded our expectations. Downtime related to screens has virtually disappeared." – Drilling Engineer, International E&P Firm.

- "Our latest order of industrial shaker screen performed beyond expectations. The extended lifespan significantly reduced our operating costs, and the fit with our existing shakers was perfect. Highly recommend their products." – Procurement Lead, Major Service Provider.

These real-world examples underscore our commitment to delivering shaker screen for sale that not only meet but exceed performance expectations in the field, contributing directly to our clients' operational success and profitability.

Ensuring Trustworthiness: Our Commitment to Quality and Support

Trust is the cornerstone of any successful partnership. Our commitment to trustworthiness is reflected in every aspect of our operations, from product design to after-sales support.

Quality Assurance & Certifications

Every Steel Frame Shale Shaker Screen is manufactured under strict quality control protocols. Our facility operates under an ISO 9001:2015 certified quality management system, ensuring consistent processes and verifiable quality at every stage. Furthermore, all relevant shaker screen for sale products comply with API RP 13C standards, which defines a rigorous method for determining shaker screen performance, including conductance and separation characteristics. We regularly conduct internal and third-party audits to maintain these high standards, providing clients with confidence in the reliability and performance of our screens. Our internal testing capabilities include mesh integrity checks, flow rate measurements, and simulated vibration tests to ensure maximum durability in the field.

Warranty and After-Sales Support

We stand behind the quality of our industrial shaker screen products. Our Steel Frame Shale Shaker Screens come with a comprehensive warranty against manufacturing defects and premature failure under normal operating conditions. Our dedicated customer support team is available to provide technical assistance, troubleshoot issues, and offer guidance on screen selection, installation, and maintenance. We maintain a robust inventory of standard screens and components to facilitate quick replacements and minimize operational downtime for our clients globally. Our service extends beyond the sale, offering expert advice and field support to optimize your solids control operations.

Delivery and Logistics

Understanding the time-sensitive nature of drilling operations, we prioritize efficient order processing and timely delivery. We have established robust logistics partnerships to ensure that your shaker screen for sale orders are dispatched promptly and arrive safely, whether by land, sea, or air cargo. Typical lead times for standard orders are X-Y business days, with expedited options available for urgent requirements. We provide comprehensive tracking information and dedicated logistics support to keep you informed every step of the way.

Frequently Asked Questions (FAQ) about Shaker Screens

To further enhance your understanding and build confidence, here are answers to common questions regarding shaker screen for sale and our Steel Frame Shale Shaker Screen.

- 1. What is a shaker screen, and why is it important in drilling?

- A shaker screen is the primary filtration component used on a shale shaker machine in drilling operations. Its importance lies in efficiently separating drilled cuttings (solids) from the drilling fluid (mud). This separation is crucial for:

- Recovering valuable drilling fluid: Reduces mud consumption and associated costs.

- Producing drier cuttings: Minimizes waste volume and disposal costs, meeting environmental regulations.

- Protecting downstream equipment: Prevents abrasive solids from damaging mud pumps, centrifuges, and other expensive components.

- Maintaining mud properties: Ensures the drilling fluid maintains its intended rheological properties and filtration characteristics for effective wellbore stability and drilling efficiency.

- 2. What materials are typically used in Steel Frame Shale Shaker Screens?

- Our Steel Frame Shale Shaker Screens primarily use high-strength Q235 steel for the frame, chosen for its excellent durability and resistance to deformation under vibration. For the screen cloth (mesh), we use premium stainless steel grades such as SS304, SS316, or SS316L. These stainless steels offer superior corrosion resistance and high tensile strength, ensuring long service life even in highly corrosive and abrasive drilling environments. The seal material is typically high-quality rubber or polyurethane (PU) to ensure a tight fit and prevent bypass.

- 3. How do I choose the correct mesh size for my application when looking for a shaker screen for sale?

- Choosing the correct mesh size (API designation) depends on several factors:

- Drilling fluid type: Water-based muds (WBM) typically allow for finer screens than oil-based muds (OBM) or synthetic-based muds (SBM).

- Drill bit type and formation: Larger cuttings from PDC bits or softer formations might initially require coarser screens.

- Desired mud purity: Finer screens remove more solids but can reduce flow rate.

- Shaker capacity: The GPM (gallons per minute) capacity of your shaker and the number of screens it accommodates.

- API RP 13C guidelines: Refer to the D100 cut point and conductance values for standardized performance comparison.

- 4. What is API RP 13C compliance, and why is it important for shaker screen products?

- API RP 13C, or API Recommended Practice 13C: Drilling Fluid Processing Equipment Evaluation, is a standardized method for evaluating the performance of shaker screen and other solids control equipment. It provides a consistent framework for measuring two key parameters:

- D100 Cut Point: The size in microns at which 100% of the solids are retained by the screen.

- Conductance: A measure of the fluid flow capacity through the screen, expressed in kD/mm (kilodarcies per millimeter).

- 5. How can I extend the lifespan of my shaker screen for sale?

- Extending screen lifespan involves a combination of proper operation and maintenance:

- Proper installation: Ensure screens are correctly seated and latched to prevent premature wear due to improper fit.

- Maintain optimal tension: If applicable, ensure screen tensioning mechanisms are functioning correctly.

- Monitor flow rates: Avoid overloading the shaker with excessive mud flow, which can cause mud pooling and accelerate screen wear.

- Regular cleaning: Periodically clean screens to prevent blinding and maintain efficiency.

- Rotate screens: If possible, rotate screens on multi-shaker setups to distribute wear evenly.

- Select appropriate mesh: Using a mesh that is too fine for the initial stage can lead to premature wear.

- Handle with care: Avoid dropping or impacting screens during transport and installation.

- 6. Do you offer custom industrial shaker screen solutions?

- Yes, absolutely. We understand that every drilling operation has unique requirements. We offer comprehensive customization services for our industrial shaker screen products, including:

- Tailoring mesh sizes and configurations to specific drilling fluid properties and desired separation efficiencies.

- Adapting frame dimensions to fit non-standard or legacy shaker models.

- Utilizing specialized materials for enhanced corrosion or abrasion resistance in extreme environments.

- 7. What is your warranty policy for Steel Frame Shale Shaker Screens?

- We offer a robust warranty for our Steel Frame Shale Shaker Screens, covering manufacturing defects and premature failure under normal operating conditions. The specific terms and duration of the warranty will be provided with your purchase agreement. We are committed to ensuring our clients receive high-quality, reliable products and provide dedicated after-sales support for any inquiries or issues.

In conclusion, the selection of a high-quality shaker screen for sale is a pivotal decision that directly impacts the efficiency, cost-effectiveness, and environmental footprint of drilling and industrial solid-liquid separation processes. Our Steel Frame Shale Shaker Screens stand as a testament to superior engineering, robust manufacturing, and unwavering commitment to performance. By leveraging advanced materials, precise manufacturing techniques, and adhering to stringent quality standards like ISO 9001 and API RP 13C, we deliver screens that not only meet but often exceed the demanding requirements of modern industry. From extending equipment lifespan and optimizing drilling fluid recovery to ensuring compliance with environmental regulations, our industrial shaker screen solutions are designed to deliver tangible benefits and contribute to your operational success. Partner with us to experience the difference that true expertise, proven experience, authoritative certifications, and unparalleled trustworthiness can make in your solids control operations.

For further reading and insights into shaker screen technology and solids control, we recommend exploring these resources:

- Society of Petroleum Engineers (SPE) Library: https://www.spe.org/en/authors/resources/technical-papers/ (Search for "shale shaker" or "solids control")

- American Petroleum Institute (API) Publications: https://www.api.org/products-and-services/pub-store (Look for API RP 13C: Recommended Practice for Shale Shaker Screen Performance)

- Drilling Contractor Magazine: https://www.drillingcontractor.org/ (Industry news and technical articles on drilling technologies)

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025