- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Cost Analysis for Galvanized Grating Key Factors and Considerations

Understanding the Cost of Galvanized Grating

Galvanized grating is an essential component in various industries, providing a durable and reliable solution for flooring, walkways, and other applications where strength and longevity are paramount. However, when planning a project, one crucial aspect to consider is the cost associated with galvanized grating. This article delves into the factors influencing the cost, methods of installation, and the advantages of choosing galvanized grating for your next project.

What is Galvanized Grating?

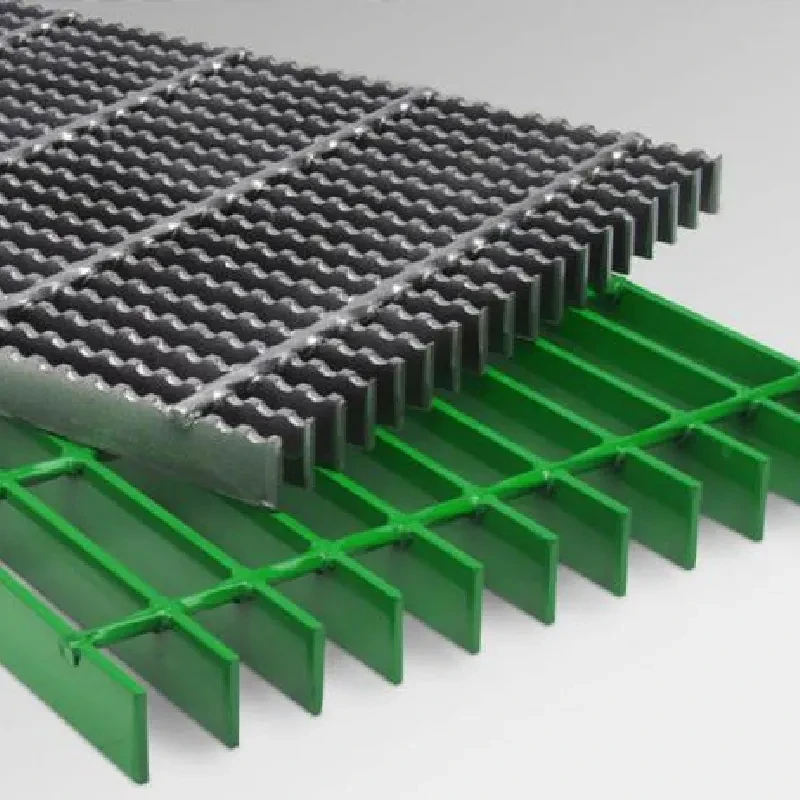

Before discussing costs, it’s crucial to understand what galvanized grating is. Galvanized grating is made from steel that has undergone a galvanization process, where it is coated with a layer of zinc to protect it from corrosion. This treatment enhances the lifespan of the grating, making it suitable for harsh environments, such as chemical processing plants, wastewater treatment facilities, and outdoor applications exposed to moisture and chemicals.

Factors Influencing Cost

1. Material Type The primary factor affecting the cost of galvanized grating is the type of steel used. While steel is generally more affordable, higher-grade steel increases the material cost but enhances durability and performance.

2. Grating Size and Thickness The dimensions of the grating—width, length, and thickness—directly impact the price. Custom sizes or thicker bars typically increase costs, as they require more material and potentially more complex manufacturing processes.

3. Welded vs. Press-locked Grating There are different manufacturing methods for galvanized grating, notably welded and press-locked. Welded grating tends to be more robust and durable, but it can also be more expensive, while press-locked options are generally lighter and may be more cost-effective for certain uses.

4. Surface Treatment Besides galvanization, additional surface treatments like powder coating or painting can increase costs further. However, these treatments can provide extra protection and aesthetic appeal, which might be worth the investment in specific projects.

5. Quantity and Project Scale Larger orders often qualify for bulk pricing discounts, which can significantly lower the per-unit cost of galvanized grating. Conversely, small orders may incur higher costs per unit due to setup fees and lower economies of scale.

6. Shipping and Delivery Since galvanized grating can be heavy and bulky, shipping expenses can also impact the overall cost. Depending on the distance and logistics, transportation fees can add to the final price.

galvanized grating cost

7. Installation Costs Lastly, installation must be factored into the total project cost. While some projects allow for DIY installation, others may require professional assistance, which can drive up costs depending on labor rates in your region.

Cost Comparison

Typically, the cost of galvanized grating can range anywhere from $10 to $30 per square foot, though this can vary widely based on the previously mentioned factors. It is advisable to obtain quotes from multiple suppliers to ensure competitive pricing and consider both initial purchase costs and long-term value due to the durability and low maintenance needs of galvanized products.

Advantages of Galvanized Grating

Despite the potentially higher costs, galvanized grating offers numerous benefits that make it a worthwhile investment

- Durability The galvanization process significantly extends the life of the grating, making it suitable for high-traffic areas and harsh conditions.

- Low Maintenance Unlike untreated steel, galvanized grating requires minimal upkeep, ultimately saving money and time in the long run.

- Safety The open grid design allows for excellent drainage and reduces the risk of slips and falls, making it ideal for wet or hazardous environments.

- Versatility Galvanized grating is versatile, used in various applications from industrial to municipal settings, adding value across different industries.

Conclusion

In conclusion, while the cost of galvanized grating may initially seem high compared to other materials, its strength, longevity, and low maintenance requirements often justify the investment. When planning your project, it's essential to consider all costing elements and seek quotes to find the best option for your needs. By doing so, you can ensure that your choice not only meets your project requirements but also stays within your budget, ultimately contributing to a successful outcome.

-

Upgrade Your Industrial Operations with Durable Steel GratingNewsJul.21,2025

-

Transform Your Flooring Solutions with Quality Floor GratingNewsJul.21,2025

-

Top-Quality Shale Shaker Screens for Your Drilling NeedsNewsJul.21,2025

-

High-Quality Steel Grating for All Your Industrial NeedsNewsJul.21,2025

-

Explore the Durability and Versatility of Galvanized Steel GratingNewsJul.21,2025

-

Ensure Maximum Safety with Premium Safety NetsNewsJul.21,2025