- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

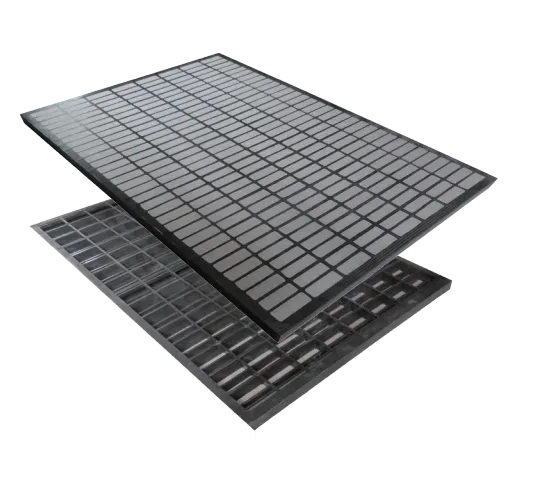

Welded Steel Bar Grating for Enhanced Durability and Safety in Industrial Applications

Understanding Welded Bar Grating A Comprehensive Overview

Welded bar grating is a highly versatile and durable material used extensively in various industrial and commercial applications. It is created by welding together flat bearing bars and cross bars at their intersections, creating a robust grid-like structure. This manufacturing technique gives welded bar grating its unique strength and stability, making it an ideal choice for flooring, walkways, and platforms in environments where safety and durability are paramount.

Construction and Materials

The primary components of welded bar grating are the bearing bars and cross bars. The bearing bars run parallel to the load direction, while the cross bars are positioned perpendicular to provide stability. The spacing between the bearing bars can be adjusted to accommodate different load requirements. Common materials used for welded bar grating include carbon steel, stainless steel, and aluminum, each chosen based on specific environmental conditions and load capacities.

Steel is the most widely used material due to its high strength-to-weight ratio and affordability. Stainless steel offers excellent corrosion resistance, making it suitable for use in harsh environments, such as food processing plants or chemical facilities. Aluminum, while lighter and more corrosion-resistant, is often chosen for lighter-duty applications.

Applications

Welded bar grating is utilized across a broad spectrum of industries. In industrial settings, it is frequently used for flooring in manufacturing plants, walkways, and mezzanines, where heavy machinery or large foot traffic is commonplace. Its open design allows for excellent drainage and ventilation, making it ideal for applications where liquids or debris may accumulate.

In the commercial sector, welded bar grating plays a crucial role in creating safe access paths, such as pedestrian bridges, stair treads, and platform flooring. Its ability to withstand substantial loads while providing safety underfoot makes it a preferred choice among architects and engineers.

Additionally, welded bar grating is often used in wastewater treatment facilities. The open design helps to facilitate water flow and drainage, while its robust construction ensures longevity despite exposure to harsh chemicals and constant use.

welded bar grating

Safety Features

Safety is a primary concern when designing any industrial or commercial facility. Welded bar grating incorporates several safety features to mitigate risks. The slip-resistant surfaces of the bars help prevent accidents, particularly in wet or oily conditions. Furthermore, the open design minimizes the likelihood of objects or debris accumulating, reducing trip hazards.

In some instances, grating can be customized with additional safety features, such as painted colors for visibility or specific coatings to enhance traction. These modifications can provide further assurance in high-risk environments.

Installation and Maintenance

The installation of welded bar grating is relatively straightforward, primarily due to its modular design. Grating panels can be easily cut and adjusted on-site to fit specific dimensions, making it a flexible solution for various projects. The panels are typically secured using clips, bolts, or welds, depending on the requirements of the application.

Maintenance requirements are generally minimal. Regular inspections should be conducted to check for signs of wear or damage, particularly in environments subject to harsh conditions. Cleaning is typically as simple as hosing down the surface to remove debris. For stainless steel and aluminum grating, occasional polishing or treatment may be required to maintain appearance and resistance to corrosion.

Conclusion

Welded bar grating is an essential solution for many industries, owing to its strength, versatility, and safety features. Whether used in heavy industrial settings, commercial buildings, or specialized applications, its benefits are clear. By understanding its construction, applications, and maintenance needs, businesses can make informed decisions that enhance safety and efficiency in their operations. As industries evolve, welded bar grating remains a critical component in promoting structural integrity and ensuring safe environments for workers and visitors alike.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025