- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

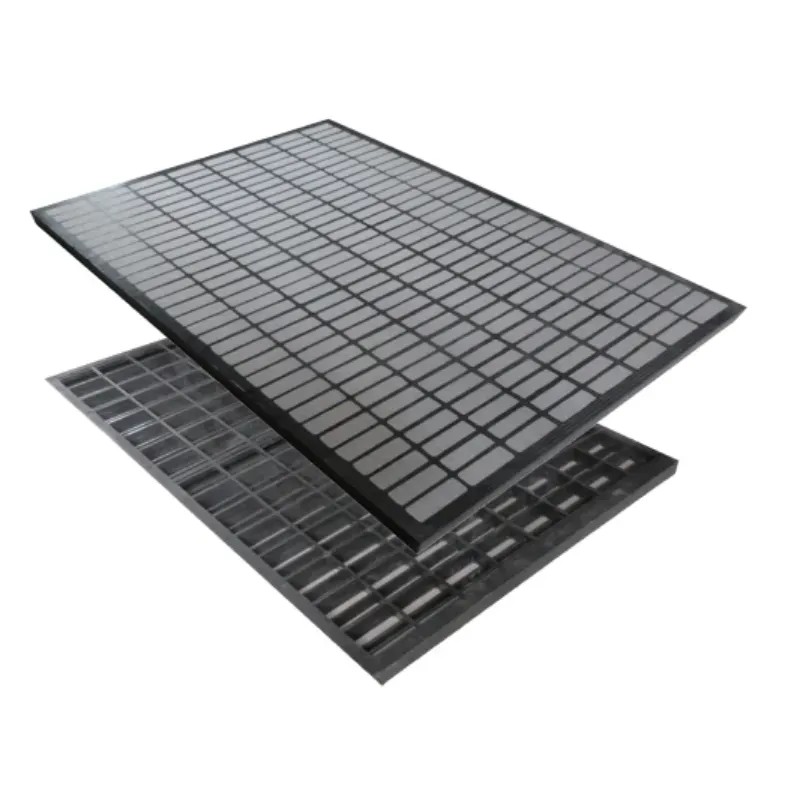

Unlock the Power of Efficient Drilling with Hangshun’s Shale Shaker Screen for Sale

When it comes to optimizing the performance of your drilling operations, the shale shaker screen is one of the most vital components of your solid control system. These essential screens are responsible for separating solids from drilling fluids, ensuring that your drilling operations run smoothly and efficiently. At Hangshun, we provide high-quality shale shaker screen for sale, designed to handle the toughest drilling conditions. Whether you're looking for a replacement part or a customized solution, Hangshun is your trusted shale shaker screen supplier.

How Does a Shale Shaker Screen Work?

A shale shaker screen is a key element in the solids control system of drilling rigs, where it works by separating the cuttings from the drilling fluid. As the drilling fluid (also known as mud) is pumped into the shale shaker, the solid particles are filtered through the mesh screen. The shaker’s motion causes the drilling fluid to pass through the screen, while the solid cuttings are left behind, ensuring that the fluid is cleaned and recirculated back into the drilling process.

Shale shaker screens operate using a combination of mesh size and tension. A properly calibrated screen will provide the right balance between efficient separation and fluid flow, contributing to overall drilling performance. As part of the shaker system, these screens help maximize the longevity of the drilling fluid, reducing waste and maintaining fluid consistency throughout the drilling process.

Types of Shale Shaker Screens: Steel or Composite Frame, Hook Screens, Wavy Screens

Shale shaker screens come in several types, each offering specific benefits depending on the nature of the drilling operation. Understanding the different types will help you choose the best option for your needs.

Steel Frame Screens: These screens are commonly used in harsh environments where durability is critical. The steel frame provides excellent strength and resistance to damage, which makes them ideal for operations involving heavy-duty, high-impact conditions. They are perfect for separating coarse solids from drilling fluids and are widely used in oil and gas exploration.

Composite Frame Screens: As an alternative to steel frame screens, composite frame screens are lighter, more flexible, and offer better resistance to corrosion. These screens are designed for operations where weight and flexibility are important, offering a longer lifespan and greater resistance to wear and tear.

Hook Screens: Known for their simplicity and effectiveness, hook screens are designed to be used with various shale shaker models. They are characterized by their hook-like structure, which provides secure attachment and easy replacement. Their efficient design allows for better fluid flow, while the mesh's tension remains stable under pressure.

Wavy Screens: These screens feature a wavy design, which helps to improve the fluid flow and solid separation during the drilling process. The wavy surface increases the screen’s ability to handle higher volumes of drilling fluids while maintaining solid control. These screens are highly effective in dealing with fine solids and offer excellent performance in finer mesh applications.

How Pore Size and Porosity of Shale Shaker Screens Affect Performance

The performance of a shale shaker screen is significantly influenced by its pore size and porosity. These two factors directly determine the screen's ability to filter solids from the drilling fluid effectively.

Pore Size: The pore size refers to the openings in the screen mesh through which the drilling fluid flows. A smaller pore size means the screen can filter out finer solids, ensuring a higher degree of fluid cleanliness. However, the smaller the pores, the less fluid the screen can process in a given amount of time. On the other hand, a larger pore size allows for higher fluid flow but may not be as effective at filtering fine particles.

Porosity: The porosity of a shale shaker screen refers to the ratio of open space to the total area of the screen mesh. A higher porosity means that there is more open space for fluid to pass through, which improves the screen’s throughput capacity. However, higher porosity can also mean a reduction in filtration efficiency for finer particles. The key is to balance both pore size and porosity to meet the specific needs of the drilling operation.

At Hangshun, we offer a variety of shale shaker screens with different pore sizes and porosities, allowing you to choose the optimal configuration for your drilling conditions.

Why Choose Hangshun as Your Shale Shaker Screen Supplier?

When you choose Hangshun as your shale shaker screen supplier, you are investing in quality, reliability, and superior performance. We understand that the success of your drilling operations depends on the efficiency and durability of your equipment. That’s why we offer only the best shale shaker screens for sale, designed to withstand the most demanding drilling environments.

Our shale shaker screen products are crafted using the latest technology and highest-quality materials, ensuring optimal performance and longevity. Whether you need a steel frame, composite frame, or wavy screen, Hangshun provides tailored solutions that meet your specific requirements.

The Advantages of Investing in High-Quality Shale Shaker Screens

Investing in top-quality shale shaker screens can greatly enhance your drilling efficiency and overall performance. High-quality screens are designed to provide excellent solid separation, which directly impacts the consistency of the drilling fluid. By maintaining optimal fluid conditions, you can reduce downtime, improve drilling efficiency, and extend the lifespan of your equipment.

Hangshun’s shale shaker screens not only offer superior filtration capabilities but also feature long-lasting durability, reducing the need for frequent replacements. This leads to lower operational costs, higher productivity, and improved results in every drilling operation.

With Hangshun’s shale shaker screens for sale, you can take your drilling operations to the next level. Whether you need a shale shaker screen for a specific type of drilling environment or you require a customized solution, we have the expertise and resources to meet your needs. Choose Hangshun as your trusted shale shaker screen supplier and experience the difference that high-quality, durable screens can make in your drilling efficiency.

Our team is committed to delivering the highest level of customer satisfaction, offering expert advice and guidance to ensure that you choose the right shale shaker screen for your operations. Visit Hangshun today and let us help you optimize your drilling performance with the best shale shaker screens on the market!

-

The Versatility of Steel Walkway GratingNewsAug.07,2025

-

The Benefits of Galvanized Steel Grating for Your ProjectsNewsAug.07,2025

-

Shaker Screens: The Ultimate Solution for Your Drilling NeedsNewsAug.07,2025

-

Perimeter Safety Net: An Essential Solution for Helipad SafetyNewsAug.07,2025

-

Enhance Safety and Efficiency with Steel Walkway GratingNewsAug.07,2025

-

Discover Exceptional Steel Grating for SaleNewsAug.07,2025