- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

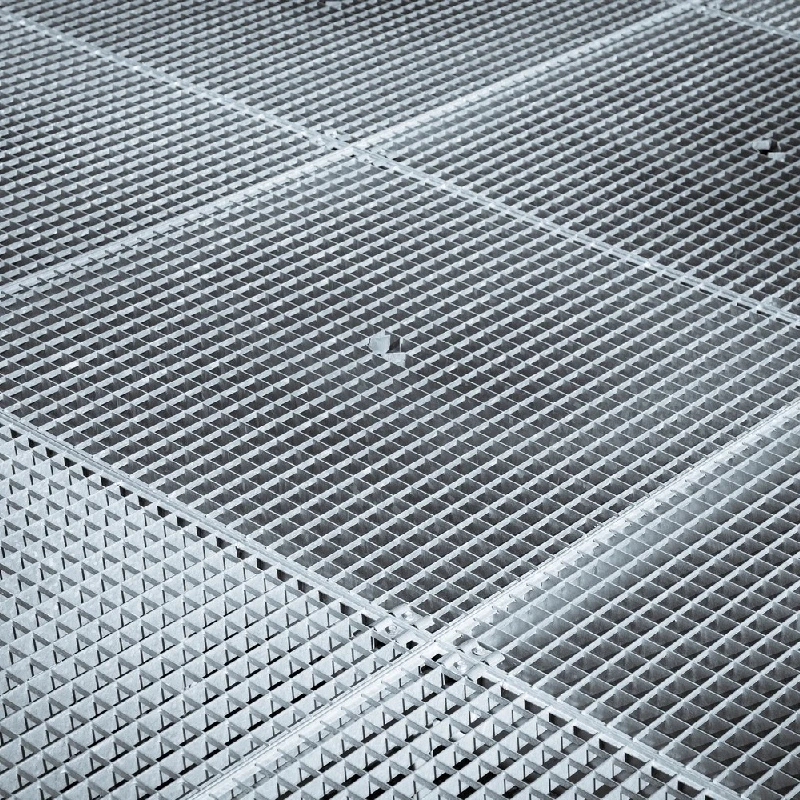

Understanding the Factors Influencing the Cost of Steel Grating and Its Applications in Industry

The Cost of Steel Grating Factors and Implications

Steel grating is a popular choice in various industries due to its robust nature, durability, and versatile application. Commonly used in walkways, platforms, and drainage covers, steel grating can significantly improve safety and efficiency in industrial environments. However, one key aspect that potential buyers must consider before making a purchase is the cost associated with steel grating. Understanding the factors that contribute to the overall price can help businesses make informed decisions.

Factors Influencing the Cost of Steel Grating

1. Material Type The cost of steel grating largely depends on the type of steel used. Common materials include carbon steel, stainless steel, and galvanized steel. Carbon steel is typically the most cost-effective option, but it may not be suitable for environments prone to corrosion. Stainless steel, while more expensive, offers superior resistance to rust and corrosion, making it ideal for marine or chemical applications. Galvanized steel provides a middle ground, combining affordability with enhanced durability due to its protective zinc coating.

2. Grating Design The design of the grating—whether it is welded or presses-locked—affects its cost. Welded grating is constructed by welding the bearing bars to the crossbars, resulting in a strong and durable product suitable for heavy loads. Press-locked grating, on the other hand, uses a press-fitting technique that may be less labor-intensive and thus, generally more affordable. The choice of design should align with the intended use and load requirements of the project.

3. Dimensions and Customization The size of the grating also plays a significant role in pricing. Standard size gratings are typically less expensive than custom-made options. Custom grating can be designed to meet specific dimensions or load-bearing criteria, which can substantially raise the cost due to the additional manufacturing processes involved. Buyers should weigh the necessity of customization against their budget.

cost of steel grating

4. Surface Treatment The surface treatment of steel grating can affect its cost. Options such as powder coating, painting, or galvanizing add additional layers of protection against environmental factors but also increase the overall price. While these treatments can enhance the longevity of the grating, entities must evaluate whether the additional expenditure is justified based on the expected lifespan and usage conditions.

5. Quantity Like many industrial products, the quantity ordered can greatly impact the cost per unit. Bulk purchases often lead to discounts, while small quantities may not benefit from the same economies of scale. Businesses should assess their needs carefully to determine whether buying in bulk can lead to savings.

Implications of Steel Grating Costs

The cost of steel grating is a critical consideration for businesses, as it directly affects project budgets and operational expenses. While it is essential to find cost-effective solutions, sacrificing quality for a lower price can lead to increased maintenance costs and safety hazards down the line. Therefore, organizations should assess their specific requirements and the conditions under which the grating will be used.

Furthermore, understanding the relationship between cost and quality can lead to better investment decisions, ultimately resulting in enhanced safety and productivity. By considering the various factors that influence the cost of steel grating—material type, design, dimensions, surface treatment, and order quantity—businesses can ensure they select the right product for their specific applications without exceeding their budget.

In conclusion, the cost of steel grating is influenced by a variety of factors that businesses must carefully evaluate. By making informed decisions, companies can achieve a balance between cost and quality, ensuring both safety and durability in their operations.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025