- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

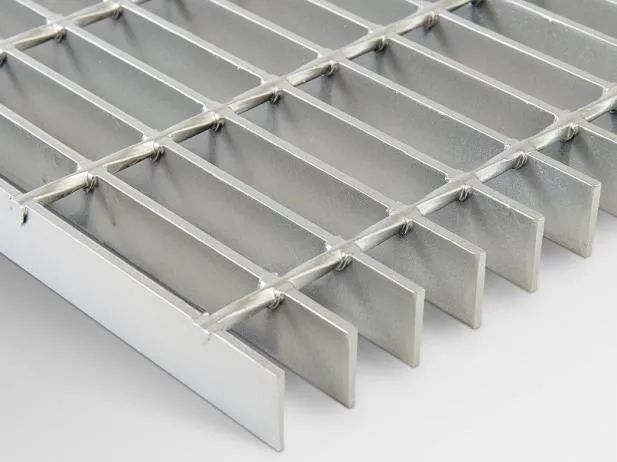

Understanding the Characteristics of 1% 201% 4 Bar Grating in Structural Applications

Understanding 1% 201% 4% Bar Grating An Overview

Bar grating, an essential component in various engineering and architectural applications, offers numerous benefits in terms of strength, durability, and aesthetics. The term 1% 201% 4% bar grating indicates specifications related to the design and function of bar grating systems. By breaking down these specifications, we can gain a clearer understanding of what this type of bar grating entails and its applications.

What is Bar Grating?

Bar grating refers to a framework of parallel bars that are designed to provide a surface that is both sturdy and open. It can be made from various materials, including steel, aluminum, and fiberglass, and is commonly used in walkways, platforms, stair treads, and as protective barriers. The physical properties of bar grating can be tailored to meet specific load requirements, making it highly versatile in construction and industrial settings.

Analyzing the Specifications 1%, 201%, and 4%

1. 1% This term could refer to the load-bearing percentage that the grating can support in a specific application. Typically, bar gratings are designed to handle varying degrees of load based upon their configuration and spacing. A 1% loading capability indicates that the grating may be suitable for lightweight applications, such as pedestrian walkways or platforms where minimal weight is expected.

2. 201% This likely denotes the material specification and the percentage of a component used in the grating's composition. A 201-grade stainless steel, for example, is often used due to its good corrosion resistance and strength, making it ideal for outdoor applications where exposure to moisture is a concern. The mention of 201% could signify an emphasis on quality control or material consistency necessary to ensure the grating meets specific industrial standards.

1 1 4 bar grating

3. 4% The final percentage may indicate the spacing between the bars or the percentage of open area within the grating. A greater open area is beneficial for drainage, ensuring that water and debris do not accumulate, which can be vital in environments exposed to elements such as construction sites or industrial areas. A spacing that allows for a 4% open area is usually ideal for both safety and functionality, especially in grating around machinery or areas requiring frequent cleaning.

Applications of Bar Grating

Bar grating has widespread applications across multiple industries. In manufacturing and processing plants, it is crucial for flooring and platforming as it allows for effective drainage while providing a stable surface for foot traffic and equipment. In municipal settings, bar grating is often used in drainage systems to cover channels and prevent debris while allowing water flow.

Another significant application of bar grating is in the construction of bridges and pedestrian walkways. The lightweight yet robust design of bar grating offers safety for pedestrians while minimizing structural load on the supporting beams.

Conclusion

1% 201% 4% bar grating exemplifies the adaptability and relevance of bar grating systems within various sectors. Understanding the specific percentages in relation to load capacity, material quality, and open area enhances the ability to select the appropriate bar grating for specific needs. With its substantial load-bearing capabilities, corrosion resistance, and functional design, bar grating continues to be a preferred choice for engineers and architects alike. The integration of such materials speaks volumes about the advancements in construction technology, ensuring durability and safety in numerous applications.

-

Why Our Shaker Screen for Sale Stands Out in Every ApplicationNewsAug.08,2025

-

Unmatched Efficiency with Premium Shale Shaker Screen TechnologyNewsAug.08,2025

-

Reliable, Durable, and Cost-Effective: Press Locked Steel Grating SolutionsNewsAug.08,2025

-

Precision Strength with Welded Steel Bar GratingNewsAug.08,2025

-

Perimeter Safety Netting: The High-Strength Shield for Elevated Safety SolutionsNewsAug.08,2025

-

Maximize Performance with Steel Walkway GratingNewsAug.08,2025