- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

The Brief Introduction of Perimeter Safety Net

Perimeter safety nets are crucial components in construction and industrial settings, providing a vital line of defense against falls and other hazards. These nets are strategically installed around the perimeter of work areas, particularly at heights, to catch falling workers, tools, or debris. The importance of perimeter safety nets in maintaining a safe work environment cannot be overstated, as they serve as a safeguard that prevents injuries and fatalities. Understanding the role, benefits, and key considerations of perimeter safety nets is essential for any industry where worker safety is a priority.

Role and Functionality of Perimeter Safety Net

The primary function of a perimeter safety net is to catch and contain falling objects, whether they are workers or materials. These nets are designed to absorb the impact of a fall, reducing the risk of serious injury or death. In construction, where workers often operate at significant heights, the use of perimeter safety nets can mean the difference between life and death. The nets act as a passive safety system, meaning they are always in place and ready to catch anything that falls, providing continuous protection.

In addition to preventing falls, perimeter safety nets also protect workers and the public from falling debris. Tools, equipment, and materials can accidentally fall from elevated work areas, posing a serious risk to those below. By containing these hazards within the net, the likelihood of injury to workers on the ground or bystanders is significantly reduced. This dual role of protecting both workers at height and those on the ground makes perimeter safety nets an indispensable part of any comprehensive safety plan.

Benefits of Perimeter Safety Nets About Perimeter Safety Net

The use of perimeter safety netting offers numerous benefits beyond just preventing falls. One of the most significant advantages is the added sense of security they provide to workers operating at heights. Knowing that there is a safety net in place can boost worker confidence, allowing them to focus more on their tasks and less on the potential danger of falling. This increased confidence can lead to greater productivity and efficiency on the job site.

Another benefit of perimeter net is their ability to reduce downtime due to accidents. When a worker falls or when debris drops from a height, it can lead to serious delays as the incident is investigated and addressed. By preventing these accidents from occurring in the first place, perimeter safety nets help keep projects on schedule and within budget. The nets also help to mitigate the potential costs associated with workplace injuries, including medical expenses, legal fees, and increased insurance premiums.

Perimeter safety nets are also relatively easy to install and maintain, making them a cost-effective safety solution. They can be quickly deployed around the perimeter of a work area, and once in place, they require minimal maintenance. This ease of use, combined with their effectiveness, makes perimeter safety nets a practical choice for a wide range of industries, from construction to shipbuilding and beyond.

Key Considerations for Effective Use About Perimeter Safety Net

To ensure that perimeter safety nets provide maximum protection, several key considerations must be taken into account. First and foremost is the quality of the netting material. The nets must be made from high-strength materials that can withstand the impact of a fall without tearing or breaking. Common materials used in the construction of perimeter safety nets include polypropylene, nylon, and polyester, each chosen for their durability and ability to absorb impact forces.

The installation of the nets is another critical factor. Perimeter safety nets must be properly anchored to the structure to ensure they can bear the load of a fall. This requires careful planning and the use of appropriate anchoring systems. The nets should also be installed with the correct amount of sag or deflection, which allows them to absorb the energy of a falling object gradually rather than abruptly stopping it, which could cause additional injury.

Regular inspection and maintenance of perimeter safety nets are also essential. Over time, exposure to the elements, such as UV rays, wind, and rain, can degrade the materials, reducing their effectiveness. Routine inspections should be conducted to check for signs of wear and tear, such as fraying, cuts, or weakened areas. Any damaged nets should be repaired or replaced immediately to ensure continued safety.

Applications Across Industries of Perimeter Safety Net

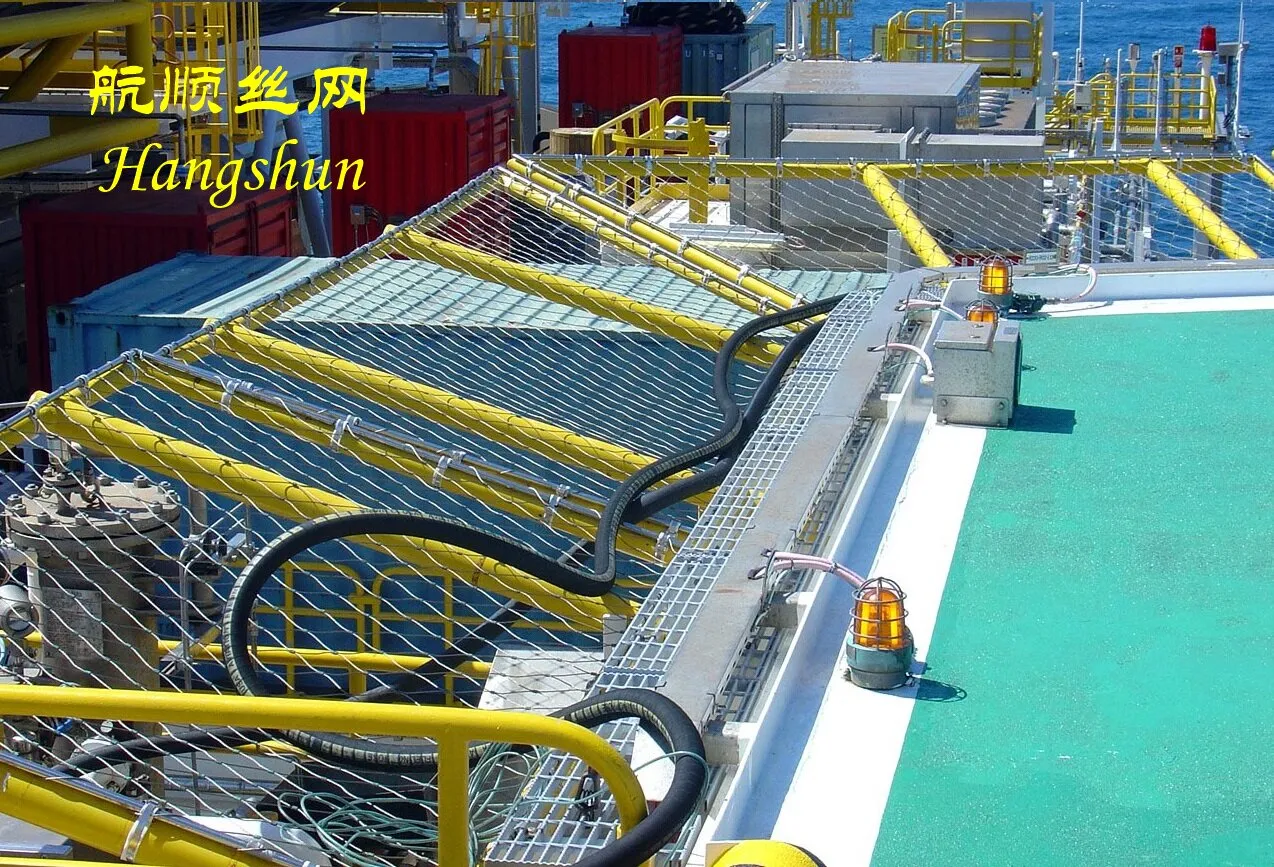

While perimeter safety nets are most commonly associated with construction, their applications extend to a variety of industries. In shipbuilding, for example, perimeter nets are used to protect workers as they perform tasks on the sides of ships or in dry docks. In the oil and gas industry, where workers often operate on offshore platforms or high scaffolding, perimeter safety nets provide crucial protection against falls into the sea or onto hard surfaces below.

Even in entertainment venues, such as theaters or arenas, perimeter safety nets can be used to protect performers and crew members working at heights. The versatility of perimeter safety nets makes them a valuable safety solution across multiple sectors, ensuring the well-being of workers and minimizing the risk of accidents.

H2: Hangshun Wire Mesh-Your Reliable Welded Wire Mesh Manufacturer

Welded wire mesh is widely used in industrial fields. Only by purchasing from trustworthy manufacturers can quality and precision be guaranteed. Hangshun Wire Mesh is a leading manufacturer of Welded wire mesh in China, With many years of industry experience and excellent reputation, is able to be your reliable supplier. Contact us now to get more information.

-

The Versatility of Steel Walkway GratingNewsAug.07,2025

-

The Benefits of Galvanized Steel Grating for Your ProjectsNewsAug.07,2025

-

Shaker Screens: The Ultimate Solution for Your Drilling NeedsNewsAug.07,2025

-

Perimeter Safety Net: An Essential Solution for Helipad SafetyNewsAug.07,2025

-

Enhance Safety and Efficiency with Steel Walkway GratingNewsAug.07,2025

-

Discover Exceptional Steel Grating for SaleNewsAug.07,2025