- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

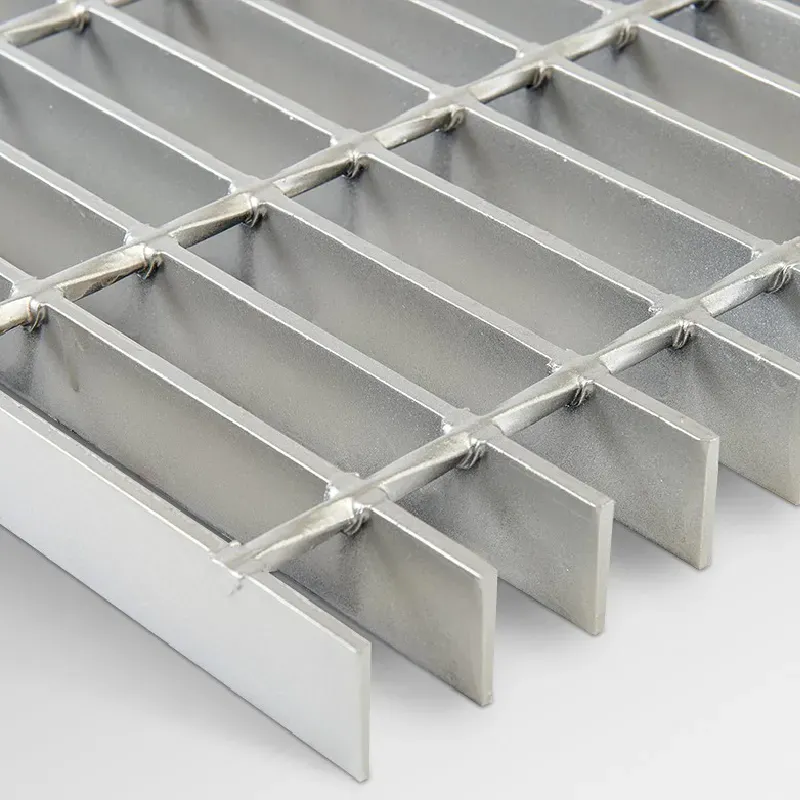

The Advantages of Steel Grating in Industrial Flooring Applications

Steel grating has become a staple in industrial flooring due to its strength, durability, and adaptability across various environments. Industries such as manufacturing, petrochemicals, mining, and transportation benefit from using steel grating for flooring, walkways, mezzanines, and platforms. With exceptional load-bearing capacity and a design that ensures both functionality and safety, steel grating is ideal for industrial settings. This article explores the key advantages of steel grating in industrial flooring applications and highlights why it’s the material of choice for heavy-duty environments.

Strength and Durability About Steel Grating

One of the foremost reasons for choosing galvanized steel grating in industrial settings is its remarkable strength and durability. Designed to withstand high loads and continuous use, steel grating can handle the heavy machinery, high foot traffic, and moving equipment typical in industrial environments. The strength of steel ensures that grating will not deform or wear down easily, maintaining its structural integrity over time. When exposed to demanding conditions, including heat, moisture, and corrosive substances, steel grating, especially galvanized or stainless steel, resists degradation better than many alternative flooring materials.

Slip Resistance for Enhanced Safety About Steel Grating

Safety is paramount in industrial environments, and expanded steel grating provides a level of slip resistance that minimizes the risk of accidents. Its open-grid design offers natural drainage for liquids, reducing the likelihood of pooling and creating a slip-free surface in wet or oily conditions. Certain types of steel grating, such as serrated or traction-tread surfaces, are specifically designed for increased grip, enhancing safety for workers who need to traverse platforms or walkways frequently. This slip-resistant feature of steel grating supports compliance with occupational safety standards, making it easier for businesses to create a safe working environment.

Efficient Ventilation and Lighting of Steel Grating

Steel grating’s open design also contributes to better ventilation and lighting, which is especially advantageous in enclosed industrial facilities. The gaps between the grating allow for the free flow of air, making it easier to ventilate areas that would otherwise trap heat or gases. In factories or refineries where ventilation is essential, steel grating helps maintain a safer and more comfortable environment for workers. Additionally, the open structure allows light to penetrate multiple levels, reducing the need for artificial lighting and contributing to energy savings. For multi-tiered floors and mezzanines, this transparency also improves visibility, which can further enhance safety.

Cost-Effectiveness and Low Maintenance About Steel Grating

Steel grating offers long-term cost savings, as its durability and minimal maintenance requirements mean less frequent repairs and replacements. Unlike other types of flooring that may crack, warp, or require frequent upkeep, steel grating is relatively low-maintenance, needing only occasional cleaning and inspections. Most steel grating products are corrosion-resistant, particularly those treated with galvanization or other protective coatings, which means that they do not require regular applications of paint or sealants. The material’s longevity and resistance to damage make it an economically sound choice, reducing overall maintenance and replacement costs over the lifespan of the structure.

Easy Customization for Various Applications About Steel Grating

Industrial facilities require flexible flooring solutions that can adapt to different layouts and needs, and steel grating’s modular nature allows for easy customization. Available in various sizes, thicknesses, and finishes, steel grating can be tailored to meet specific load requirements and environmental conditions. Custom-sized grates can be created to fit non-standard spaces, and different grating types, such as welded, press-locked, or swage-locked, provide unique benefits depending on the application. This adaptability is particularly valuable for industries with specialized equipment setups or space constraints, allowing for efficient use of floor space and seamless integration with existing infrastructure.

Environmental Benefits of Using Steel Grating

The environmental benefits of steel grating are an added advantage, as steel is a recyclable material that can be repurposed or melted down for reuse. In the face of growing environmental concerns, industries are increasingly seeking sustainable building materials, and steel grating aligns with green building practices. Many steel grates contain recycled materials, which contributes to a reduced carbon footprint. Furthermore, at the end of its useful life, steel grating can be recycled, reducing waste and supporting circular economy initiatives.

Applications Across Various Industrial Settings With Steel Grating

Steel grating’s versatility makes it a valuable choice across diverse industrial applications. In manufacturing plants, it is commonly used for walkways and access platforms, providing a durable surface that can handle the wear and tear of continuous foot traffic and heavy machinery. Mining operations, which often face harsh, abrasive environments, benefit from steel grating’s resistance to dirt, debris, and corrosive substances. In chemical processing facilities, steel grating is ideal for platforms and catwalks due to its corrosion resistance and ability to handle spills without pooling. Additionally, in warehouses and distribution centers, steel grating can support efficient drainage, ensuring that areas prone to liquid exposure remain dry and safe.

-

Unlocking Efficiency with Premium Shaker ScreensNewsAug.05,2025

-

Safety and Style with Metal Grate WalkwayNewsAug.05,2025

-

Optimize Operations with Shaker Screen SolutionsNewsAug.05,2025

-

Enhance Your Space with Steel GratingNewsAug.05,2025

-

Durability with Concrete Weight Coating MeshNewsAug.05,2025

-

Discover the Power of Perimeter Safety NetNewsAug.05,2025