- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

High-Performance Shaker Screens for Efficient Solids Control Solutions

Understanding SWACO Shaker Screens A Comprehensive Guide

In the oil and gas industry, the efficient separation of drilling fluid is crucial for maintaining the integrity of operations while maximizing productivity. One of the key components in this process is the shaker screen, specifically SWACO shaker screens, widely recognized for their quality and performance.

What are SWACO Shaker Screens?

SWACO shaker screens are specialized filtration devices used in drilling operations, particularly in the shale shaker—a vital piece of equipment that separates solids from the drilling fluid. These screens work by allowing the drilling fluid to pass through while capturing larger solid particles, thereby ensuring that the fluid used in the drilling process remains effective and efficient.

The Importance of Shaker Screens in Drilling Operations

In the drilling industry, maintaining the properties of drilling fluid is essential. The presence of solids can significantly affect the fluid's viscosity, density, and overall performance. This is where shaker screens play a pivotal role. By removing unwanted solids, SWACO shaker screens help to

1. Reduce Fluid Loss Contaminants in drilling fluid can lead to significant losses, increasing costs and reducing operational efficiency. By effectively filtering out solids, these screens help maintain optimal fluid conditions. 2. Improve Drilling Performance Cleaner drilling fluid can enhance the rate of penetration, leading to more efficient drilling operations. This boost in performance can result in time and cost savings—critical factors in the competitive oil and gas market.

3. Protect Downhole Equipment Excessive solids can cause wear and tear on drilling equipment. By utilizing SWACO shaker screens to maintain fluid cleanliness, operators can prolong the lifespan of crucial components and reduce downtime caused by repairs or replacements.

Design and Features of SWACO Shaker Screens

SWACO shaker screens come in various designs and configurations to cater to different drilling needs. They are typically constructed with durable materials that can withstand the harsh conditions of drilling environments. Some key features include

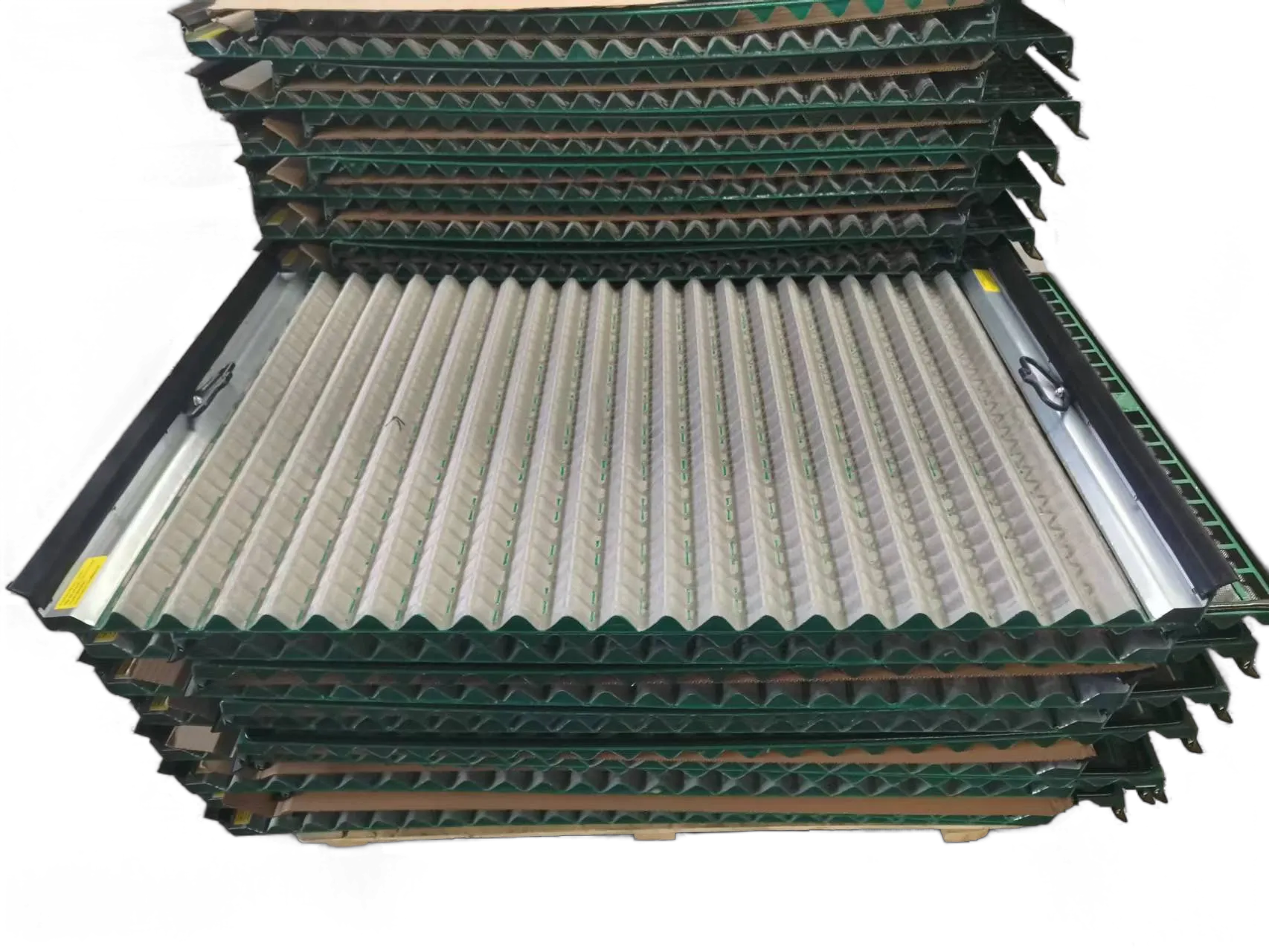

swaco shaker screens

- Mesh Size Variety SWACO offers screens with different mesh sizes, allowing operators to select the appropriate filtration level based on the specific requirements of their drilling operations. Smaller mesh sizes can capture finer particles, while larger sizes are suited for coarser solids.

- Structural Integrity The screens are designed to maintain their shape and performance even under high-pressure and high-flow conditions. This structural integrity is essential for providing consistent results throughout the drilling process.

- Easy Installation and Maintenance SWACO shaker screens are engineered for quick installation and maintenance, minimizing downtime during operations. This feature is particularly valuable for crews working in fast-paced environments where time efficiency is critical.

Selecting the Right SWACO Shaker Screen

Choosing the right shaker screen is crucial for maximizing efficiency and effectiveness in drilling operations. Factors to consider include

1. Type of Drilling Fluid The characteristics of the drilling fluid, including its viscosity and density, should guide the selection of mesh size and screen type.

2. Type of Solids Encountered Understanding the kinds of solids likely to be encountered during drilling can help determine the most suitable screen configuration.

3. Operational Goals Different drilling projects may have unique goals regarding efficiency, cost, and performance. Operators should align their choice of screens with these objectives for optimal results.

Conclusion

SWACO shaker screens are integral to the drilling process within the oil and gas industry, providing essential filtration solutions that enhance efficiency, performance, and equipment longevity. By understanding the importance of these screens and selecting the right type for specific drilling needs, operators can significantly improve the quality of their drilling fluid management and overall operational success. As technology continues to evolve, the role of such equipment will only become more pronounced in the quest for efficient and sustainable drilling practices.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025