- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Jan . 14, 2025 10:48

Back to list

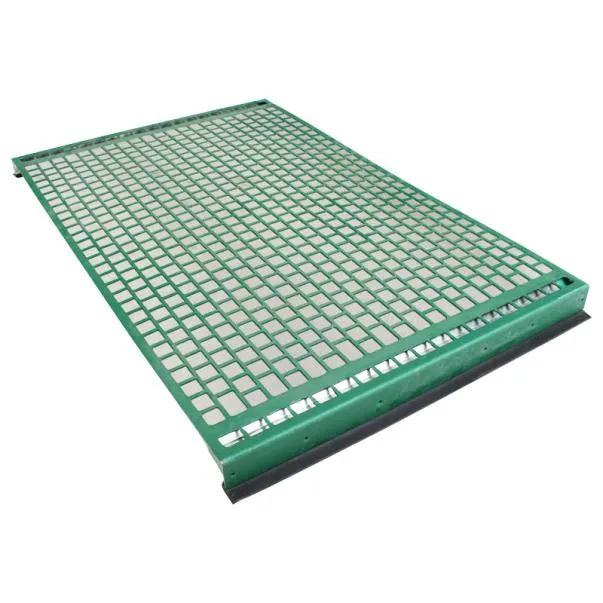

steel walkway grating

Navigating industrial environments requires a keen understanding of the materials and constructions that ensure both safety and efficiency. Floor forge walkway steel grating is an indispensable component in many industrial settings, offering an unparalleled combination of strength, durability, and customizability. As an expert in industrial material solutions, I am excited to share insights into why this product is pivotal for numerous applications.

Furthermore, integrated safety features, such as serrated surfaces, enhance the non-slip properties of the grating, proving critical in environments prone to grease, water, or chemical spills. This level of detail demonstrates the depth of commitment manufacturers have towards creating trustworthy products that meet stringent safety regulations globally. The trust is further underlined by the industry standards these products align with, such as ASTM and OSHA, ensuring worldwide compliance and reliability. Durability is another area where steel grating proves authoritative. It's not uncommon for this material to withstand harsh environments, including extreme temperatures and corrosive elements, for decades without significant degradation. This longevity reduces the need for frequent replacements, bringing down long-term maintenance costs and improving facility uptime. Recyclability of steel adds an environmental dimension often appreciated in sustainability-focused industries. Since steel can be recycled multiple times without compromising its integrity, floor forging walkways not only contribute to immediate operational benefits but also position users as responsible stewards of the environment — a critical factor in modern corporate ethics. Acknowledging these unequivocal advantages, organizations globally are rapidly adopting floor forge walkway steel grating as their premium choice for flooring and platform solutions. The combination of practical experience, expert engineering oversight, and adherence to authoritative safety standards creates a reliable framework that businesses can trust wholeheartedly. Investing in these gratings isn't just a purchase; it's a strategic decision to enhance operational safety and efficiency while committing to sustainable practices in industrial design.

Furthermore, integrated safety features, such as serrated surfaces, enhance the non-slip properties of the grating, proving critical in environments prone to grease, water, or chemical spills. This level of detail demonstrates the depth of commitment manufacturers have towards creating trustworthy products that meet stringent safety regulations globally. The trust is further underlined by the industry standards these products align with, such as ASTM and OSHA, ensuring worldwide compliance and reliability. Durability is another area where steel grating proves authoritative. It's not uncommon for this material to withstand harsh environments, including extreme temperatures and corrosive elements, for decades without significant degradation. This longevity reduces the need for frequent replacements, bringing down long-term maintenance costs and improving facility uptime. Recyclability of steel adds an environmental dimension often appreciated in sustainability-focused industries. Since steel can be recycled multiple times without compromising its integrity, floor forging walkways not only contribute to immediate operational benefits but also position users as responsible stewards of the environment — a critical factor in modern corporate ethics. Acknowledging these unequivocal advantages, organizations globally are rapidly adopting floor forge walkway steel grating as their premium choice for flooring and platform solutions. The combination of practical experience, expert engineering oversight, and adherence to authoritative safety standards creates a reliable framework that businesses can trust wholeheartedly. Investing in these gratings isn't just a purchase; it's a strategic decision to enhance operational safety and efficiency while committing to sustainable practices in industrial design.

Share

Prev:

Latest news

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025