- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

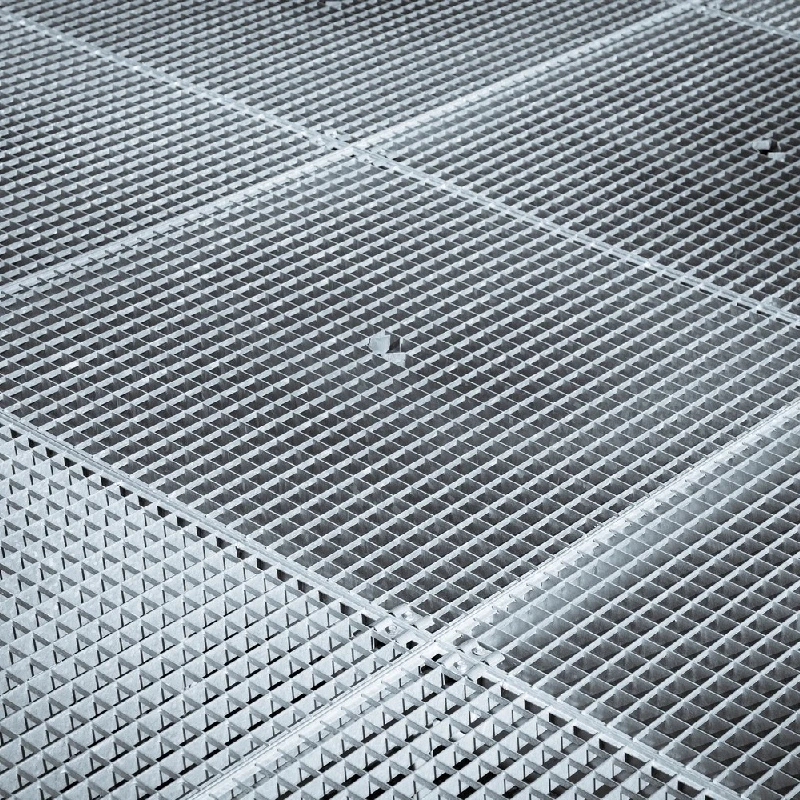

steel platform grating

The Versatility and Importance of Steel Platform Grating

Steel platform grating is a critical component in various industrial and commercial applications, providing both structural support and safety features in environments where durability and corrosion resistance are paramount. This article explores the diverse uses, benefits, manufacturing processes, and future prospects of steel platform grating.

Understanding Steel Platform Grating

Steel platform grating is a type of flooring system made from steel bars that are welded together to form a grid-like structure. This design allows for maximum open space, providing drainage and ventilation while maintaining strength and stability. The spaces between the bars also minimize the accumulation of debris and reduce the slip hazard, making it an optimal choice for industrial settings, walkways, and platforms.

Variety of Applications

Steel grating is used extensively in numerous sectors. In industrial environments, it serves as a walkway in factories, chemical plants, and refineries where heavy equipment and machinery operate. It allows workers to navigate safely above potentially hazardous areas while providing unobstructed access to critical equipment.

In the construction industry, steel platform grating is prevalent in the creation of mezzanines and platforms that require lightweight yet durable structural components. Additionally, it is widely utilized in wastewater treatment facilities to create grates for clarifiers and channels, ensuring that water flow remains unobstructed while supporting workers and maintenance vehicles.

Furthermore, steel grating finds its place in commercial settings such as shopping malls and stadiums, where it provides a safe, slip-resistant surface for large crowds. It’s also used in the energy sector for oil rigs and renewable energy facilities, playing a crucial role in safety and functionality.

Advantages of Steel Platform Grating

One of the primary benefits of steel platform grating is its strength-to-weight ratio, which allows for considerable load-bearing capacity without the need for excessive material. This characteristic is particularly beneficial in applications where weight must be kept to a minimum while still requiring significant structural support.

steel platform grating

Durability and corrosion resistance are additional advantages. Steel grating can be coated with protective materials to enhance resistance against harsh environmental conditions, including chemicals and extreme weather. This coatings extend the life of the grating, ensuring the safety and integrity of the structures using it.

Moreover, steel grating is generally easy to install and maintain. Its modular nature allows for quick assembly and disassembly, facilitating straightforward replacement or repair as needed. This efficiency not only saves time but also reduces labor costs associated with installation and upkeep.

Manufacturing Process

The fabrication of steel platform grating typically involves several steps, including material selection, cutting, welding, and finishing. High-quality steel is chosen for its exceptional strength and durableness. The manufacturing process begins with precision cutting of the steel bars, followed by automated or manual welding to create the desired grid pattern.

Post-welding, the grating is subjected to finishing processes such as galvanization, powder coating, or painting to enhance its aesthetic and protective properties. These finishes are essential for preventing rust and corrosion, making the grating suitable for both indoor and outdoor applications.

Future Prospects

As industries increasingly prioritize safety and sustainability, the demand for advanced steel platform grating solutions is expected to grow. Innovations in material science may lead to the development of composite grating options that incorporate lightweight materials without compromising strength. These advancements could further enhance the applicability of steel grating in more diverse and demanding environments.

Additionally, the growing emphasis on eco-friendly construction practices could lead to an uptick in the use of recycled steel in manufacturing grating products. This shift not only aids in reducing the environmental impact of construction but also promotes the circular economy.

Conclusion

In conclusion, steel platform grating plays a vital role in a multitude of industries, providing essential safety, durability, and versatility in various applications. As technology advances, and with increased focus on sustainability, it is likely that steel grating will evolve to meet new challenges and standards. Its importance in construction, maintenance, and industrial safety will ensure that it remains a fundamental element in the infrastructure of the future, supporting both personnel and equipment in an ever-changing world.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025