- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

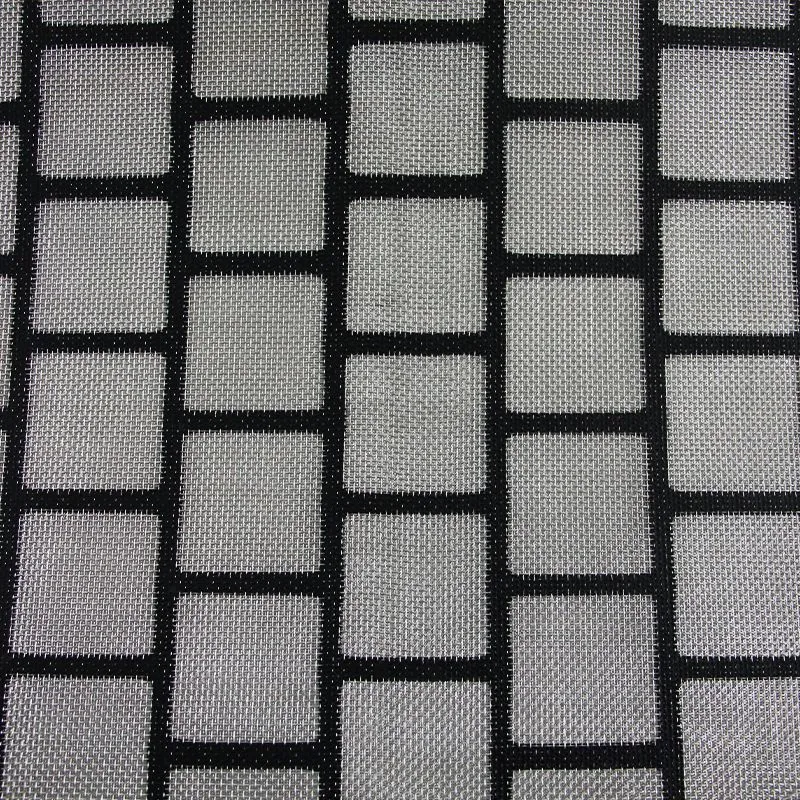

steel metal grating

Understanding Steel Metal Grating Applications, Benefits, and Maintenance

Steel metal grating is a versatile and durable solution widely used in various industries, from construction and infrastructure to manufacturing and transportation. This article delves into the properties, applications, benefits, and maintenance considerations of steel metal grating.

What is Steel Metal Grating?

Steel metal grating is a type of flooring or walkway system made from a series of parallel bars, rods, or strips welded together to create a grid-like structure. The most common types of steel grating include welded steel grating, molded grating, and pressure-locked grating. These gratings are typically made from carbon steel, stainless steel, or aluminum, with steel providing exceptional strength and durability.

Applications of Steel Metal Grating

Steel metal grating is extensively used in various applications

1. Industrial Flooring One of the primary applications is as flooring in industrial settings, such as factories, warehouses, and power plants. Its anti-slip surface offers safety while allowing for drainage, reducing the risk of puddles that can cause accidents.

2. Walkways and Platforms Steel grating is an excellent choice for elevated walkways and platforms in outdoor and indoor environments. Its open design ensures visibility and ventilation while allowing water and debris to pass through.

4. Stair Treads Grating can be customized for stair treads, offering slip resistance in high-traffic areas. It can be painted or coated to enhance visibility and safety.

5. Safety Barriers Steel grating can also be utilized as safety barriers or guardrails in various settings, protecting against falls and enhancing the security of elevated structures.

steel metal grating

Benefits of Steel Metal Grating

1. Strength and Durability One of the primary advantages of steel metal grating is its exceptional strength, which can support heavy loads while resisting deformation. This durability ensures a long lifespan, making it a cost-effective solution over time.

2. Slip Resistance Most steel gratings feature a surface treated to enhance slip resistance, which is crucial in high-traffic areas where liquids might be present.

3. Easy Installation and Maintenance Steel grating is relatively easy to install and can be cut to size or modified to meet specific project requirements. Regular maintenance primarily involves cleaning, which can be done using a pressure washer or regular sweeping to remove debris.

4. Versatility The versatility of steel metal grating allows it to be used in a wide range of applications, providing functional solutions in numerous environments. It can be customized in terms of thickness, spacing, and finish to meet specific needs.

5. Eco-friendly Option Steel is a recyclable material, and using steel grating contributes to sustainability. At the end of its service life, the material can be repurposed, reducing waste and promoting eco-friendliness.

Maintenance Considerations

While steel metal grating is robust, certain maintenance practices can help prolong its lifespan. Regularly inspecting the grating for signs of wear, corrosion, or rust is essential, especially in outdoor or corrosive environments. If using carbon steel, applying a protective coating or paint can help prevent rusting. Cleaning the grating periodically also keeps it free from debris that could pose safety hazards.

Conclusion

Steel metal grating is a practical and efficient solution for various industrial applications, offering strength, safety, and durability. Its versatility and ease of maintenance make it an excellent choice for architects, engineers, and contractors across multiple sectors. By understanding its properties and applications, businesses can make informed decisions when incorporating this material into their projects, ensuring safety and efficacy in their operations.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025