- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

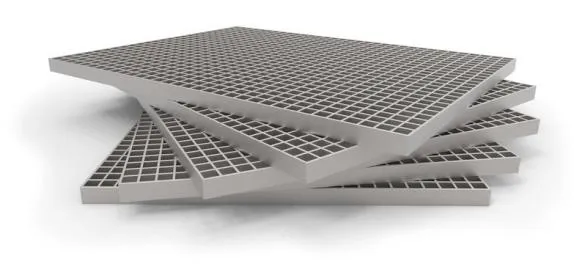

Understanding the Weight Calculation of Steel Gratings for Structural Applications

Understanding Steel Grating Weights A Comprehensive Overview

Steel grating is an integral component in numerous industrial and commercial applications, serving as a reliable platform for pedestrian walkways, access to machinery, and drainage systems. One of the key considerations when selecting steel grating is its weight, which can influence both the installation process and the overall structural integrity of the project. In this article, we will delve into the factors that affect the weight of steel grating, its importance in engineering, and how to calculate it based on various specifications.

Factors Influencing Steel Grating Weight

1. Material Composition The primary material used in the production of steel grating is carbon steel, which can be galvanized for corrosion resistance. The type of steel and any additional coatings will affect the overall weight. Stainless steel grating, for instance, is heavier due to its alloy composition.

2. Grating Type There are several types of steel grating, including welded, pressed, and swaged. Each type has a unique manufacturing process that influences weight. For instance, welded grating typically has a higher weight compared to pressed grating due to the additional materials used during construction.

3. Bar Size and Spacing The dimensions of the load-bearing bars that make up the grating—both their thickness and spacing—greatly impact the weight. Thicker bars or closely spaced bars provide added strength and support, resulting in increased weight.

4. Dimensions The size of the grating panels plays a crucial role in determining weight. Larger panels will naturally weigh more due to the increased amount of material used. Standard panel sizes can range, but larger dimensions will also pose challenges in terms of handling and installation.

Importance of Grating Weight in Engineering

Understanding the weight of steel grating is essential for structural engineers and designers

. The weight affects several aspects of a projectsteel grating weights

- Load Bearing Capacity The weight of the grating has a direct correlation with its ability to support loads. Choosing the right weight class for a specific application ensures that the grating will endure the expected traffic, whether it be foot traffic, vehicular access, or heavy machinery.

- Transport and Installation Heavier grate sections can complicate logistics, requiring additional manpower and equipment for transport and installation. Understanding the weight can help in planning these operations efficiently.

- Cost Generally, heavier grating may cost more due to the volume of materials used. However, the choice of grating must also balance cost with the required strength and durability.

Calculating Steel Grating Weights

To determine the weight of steel grating, one can use the following formula

\[ \text{Weight (lbs)} = \text{Length (in)} \times \text{Width (in)} \times \text{Material Weight per Sq Ft (lbs/ft²)} \]

For most types of steel grating, the material weight will be provided by the manufacturer. By understanding your specific requirements and applying the formula based on the chosen materials and dimensions, you can estimate the total weight for your project.

Conclusion

Steel grating plays a vital role in infrastructure and industrial designs. A thorough understanding of the factors influencing its weight is essential for making informed decisions in design, safety, and cost-efficiency. By considering the type of grating, material composition, dimensions, and load requirements, engineers can select the most suitable steel grating that meets the necessary standards while ensuring the project's success. As industries continue to innovate, staying informed about material properties and their implications will remain key to achieving optimal results in steel grating applications.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025