- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Choosing the Right Thickness for Steel Grating Applications in Construction and Industry

Understanding Steel Grating Thickness A Comprehensive Guide

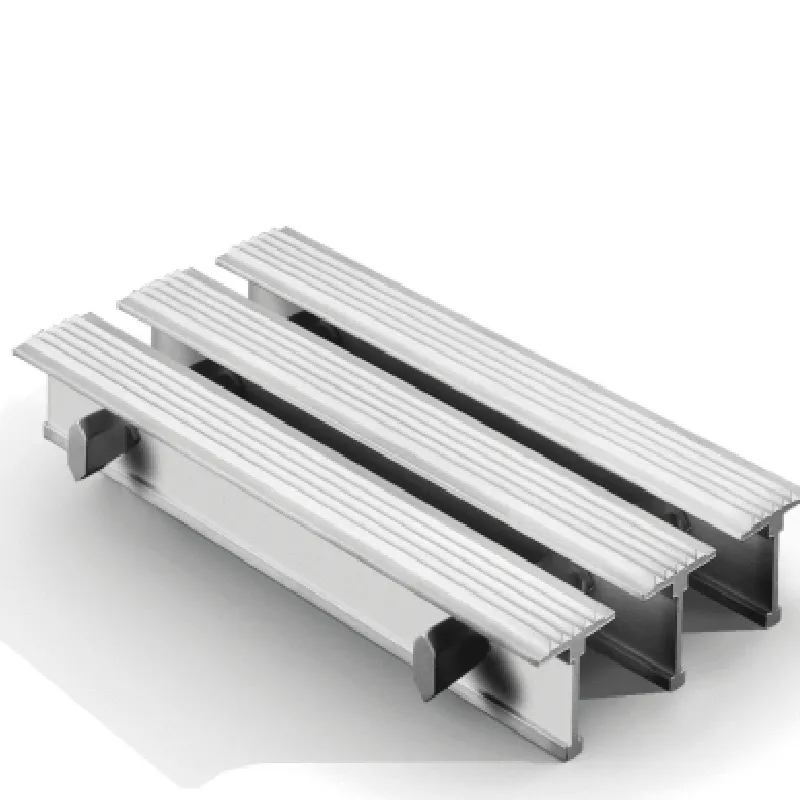

Steel grating is an essential component in various industrial applications, providing support and safety in environments where heavy loads and high traffic occur. Its structure allows for efficient drainage and aeration, making it a versatile choice for walkways, drainage covers, and platforms. One key aspect of steel grating that must be carefully considered during the design and installation process is its thickness.

What is Steel Grating?

Before delving into thickness, it’s important to understand what steel grating is. Steel grating consists of a series of parallel bars that are joined together by perpendicular bars. The bars are usually spaced apart to allow light, air, and water to pass through while providing a sturdy surface for pedestrians and vehicles. Common types of steel grating include welded, lock-shaped, and riveted designs, each catering to specific needs and applications.

Importance of Grating Thickness

The thickness of steel grating is a critical factor in determining its load-bearing capacity, longevity, and overall performance. Thicker grating offers increased strength and durability, making it suitable for heavy-duty applications, such as industrial facilities, warehouses, and off-shore platforms. In contrast, thinner grating is generally used for lighter loads and can be advantageous for applications where weight savings are essential.

1. Load-Bearing Capacity The primary concern when selecting the thickness of steel grating is its ability to support expected loads. Grating that is too thin may deform or fail under heavy loads, posing safety risks. Manufacturers provide load ratings based on specific thicknesses and spacing, allowing engineers to choose the appropriate thickness for a given application.

2. Durability and Longevity Thicker grating tends to have a longer lifespan due to its ability to withstand wear and tear from foot traffic, vehicular movement, and environmental factors. In corrosive environments, higher thickness can also give added protection against rust and degradation, extending the product's usability.

steel grating thickness

3. Safety Considerations Safety is paramount in any industrial application. Thicker grates provide a more stable surface, reducing the risk of accidents caused by bending or breaking under weight. Additionally, the choice of thickness can influence the grating's resistance to impact and dynamic loads, which are particularly relevant in areas near heavy machinery.

Choosing the Right Thickness

Selecting the appropriate thickness for steel grating involves several considerations

- Load Requirements Evaluate the maximum load the grating will need to support. Refer to manufacturer specifications to choose a thickness that meets or exceeds this requirement. - Environment Consider the environmental factors that may affect grating performance, such as exposure to corrosive substances, moisture, and temperature variations. Heavy-duty jobs in hostile environments may necessitate thicker grating.

- Type of Use Understand the specific use cases for the grating. Areas subject to frequent and heavy traffic must prioritize thicker grating, while light pedestrian paths may use thinner alternatives.

- Code Compliance Adhere to local building codes and safety regulations, which may stipulate minimum thickness requirements for certain applications.

Conclusion

In conclusion, the thickness of steel grating is a fundamental aspect that influences its overall performance, safety, and longevity. By carefully considering load requirements, environmental conditions, and intended use, decision-makers can select the appropriate thickness to ensure optimal functionality. This attention to detail not only enhances safety but also contributes to the cost-effectiveness of the installation over time. With proper specifications, steel grating can serve as a durable and reliable solution in a variety of industrial settings.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025