- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

steel grating standard sizes

Understanding Steel Grating Standard Sizes

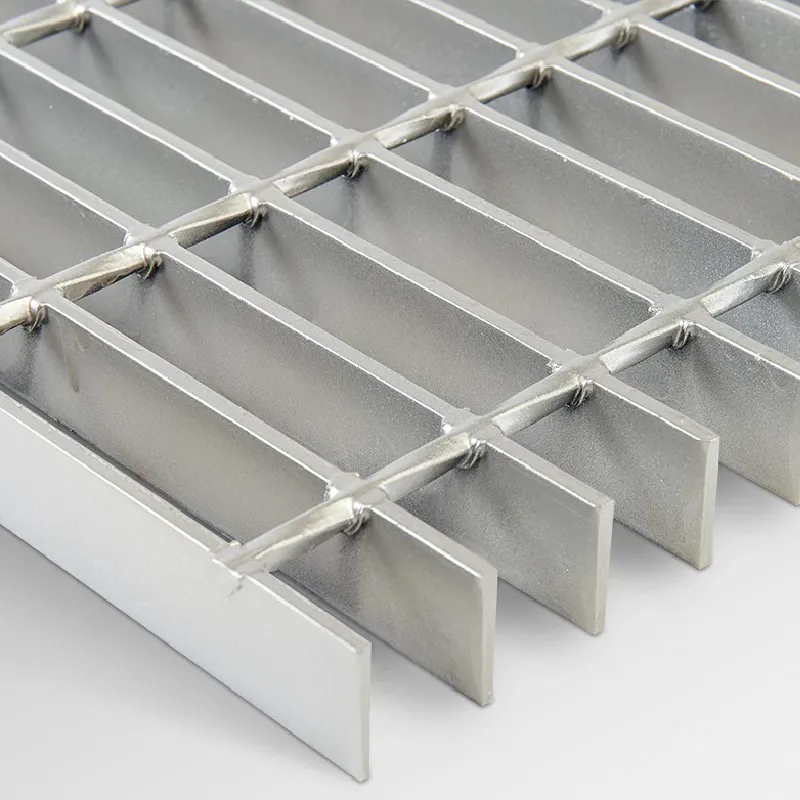

Steel grating is a versatile material that plays an essential role in various industries, from construction to manufacturing. It is designed to support heavy loads while allowing for easy drainage and ventilation. Understanding the standard sizes of steel grating is crucial for selecting the right type for specific applications, ensuring safety and efficiency.

What is Steel Grating?

Steel grating consists of flat bars, known as bearing bars, that are parallel to each other and supported by cross bars welded at regular intervals. This grid-like structure provides strength and durability, making it suitable for numerous applications, including walkways, platforms, stair treads, and drainage covers. Steel grating is favored for its lightweight yet robust characteristics, allowing it to endure significant stress while maintaining structural integrity.

Standard Sizes of Steel Grating

1. Bearing Bar Sizes The bearing bars are typically made from carbon steel, stainless steel, or aluminum. Standard widths include 19, 20, and 30 mm, with various thicknesses ranging from 1.5 mm to 6 mm. Common spacing between bars can be from 30 to 40 mm apart, depending on the specific load requirements and intended use.

2. Panel Sizes The standard panel sizes for steel grating often range from 1 meter by 2 meters to 1.2 meters by 3 meters. These dimensions are designed to streamline installation and fit standard construction layouts. The choice of panel size often depends on factors such as the project’s load capacity requirements and available space.

3. Cross Bar Sizes Cross bars, which provide additional support, are often made from the same material as the bearing bars. Standard diameters for cross bars range from 5 mm to 10 mm. The spacing between cross bars can vary based on load requirements but is typically 30 to 100 mm.

4. Load Ratings Steel grating is categorized based on its load-bearing capabilities, often classified as light, medium, or heavy-duty. Light-duty gratings are suitable for pedestrian traffic, whereas medium-duty grating can support both pedestrian and light vehicle traffic. Heavy-duty grating is engineered for applications involving heavy machinery and vehicular traffic. Load capacity is a vital consideration when selecting steel grating, as it directly impacts safety and durability.

steel grating standard sizes

5. Surface Treatments and Finishes Standard sizes of steel grating can also vary based on finishing processes. Surface treatments like galvanization, powder coating, or anodizing improve corrosion resistance and enhance the visual appeal of the grating. Galvanized steel grating is particularly popular due to its ability to withstand harsh environmental conditions.

Applications of Steel Grating

Steel grating is employed across various sectors

- Industrial Facilities Used for flooring, platforms, and stair treads, providing safe passage for workers and machinery. - Oil and Gas Industries Critical in refineries and offshore platforms, where durability and safety are paramount. - Water Treatment Plants Facilitates movement while allowing for drainage and avoiding clogging. - Commercial Buildings Used in decorative walkways and as security barriers. - Transportation Applied in bridges and airport ramp systems for safe vehicle movement.

Selecting the Right Steel Grating

When selecting steel grating, it's essential to consider several factors, including load requirements, environmental conditions, and the specific application. Consulting with manufacturers or suppliers who can provide guidance on standard sizes and load capacities will aid in making informed decisions.

Conclusion

Understanding the standard sizes of steel grating is fundamental for ensuring safety, efficiency, and durability in various applications. By taking into account bearing bar sizes, panel dimensions, load ratings, and specific industrial needs, architects, engineers, and builders can make well-informed choices that cater to their project requirements. In an industry where safety is a priority, selecting the right steel grating can make a significant difference in both performance and longevity.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025