- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Standard Dimensions for Steel Grating and Their Applications in Construction Industry

Understanding Steel Grating Standard Sizes

Steel gratings are integral components in various industrial applications, architecture, and construction. Their main purpose is to provide strength while allowing light, air, and fluids to pass through. Due to their durability and support, they are widely used in walkways, platforms, drainage covers, and stair treads. However, to ensure safety and efficiency, it's essential to adhere to standard sizes in the fabrication and installation of steel gratings. In this article, we will explore the significance of standard sizes, various applications, and factors influencing the choice of size and style.

Importance of Standard Sizes

Standard sizes for steel gratings are established to maintain compatibility, interchangeability, and uniformity in applications. These dimensions not only facilitate easier design and engineering processes but also ensure that products conform to regulatory standards. Companies and project managers can effectively plan layouts and select materials that will fit existing structures without the need for extensive modifications.

Moreover, using standard sizes can significantly reduce costs and lead time in procurement. Suppliers often keep these sizes in stock, enabling quicker delivery and lowering the overall project expenditure. For end-users, knowing the standard sizes allows for better decision-making in terms of quality, pricing, and convenience.

Common Standard Sizes

While the specific sizes can vary by region and manufacturer, the most commonly used standard sizes for steel gratings often include

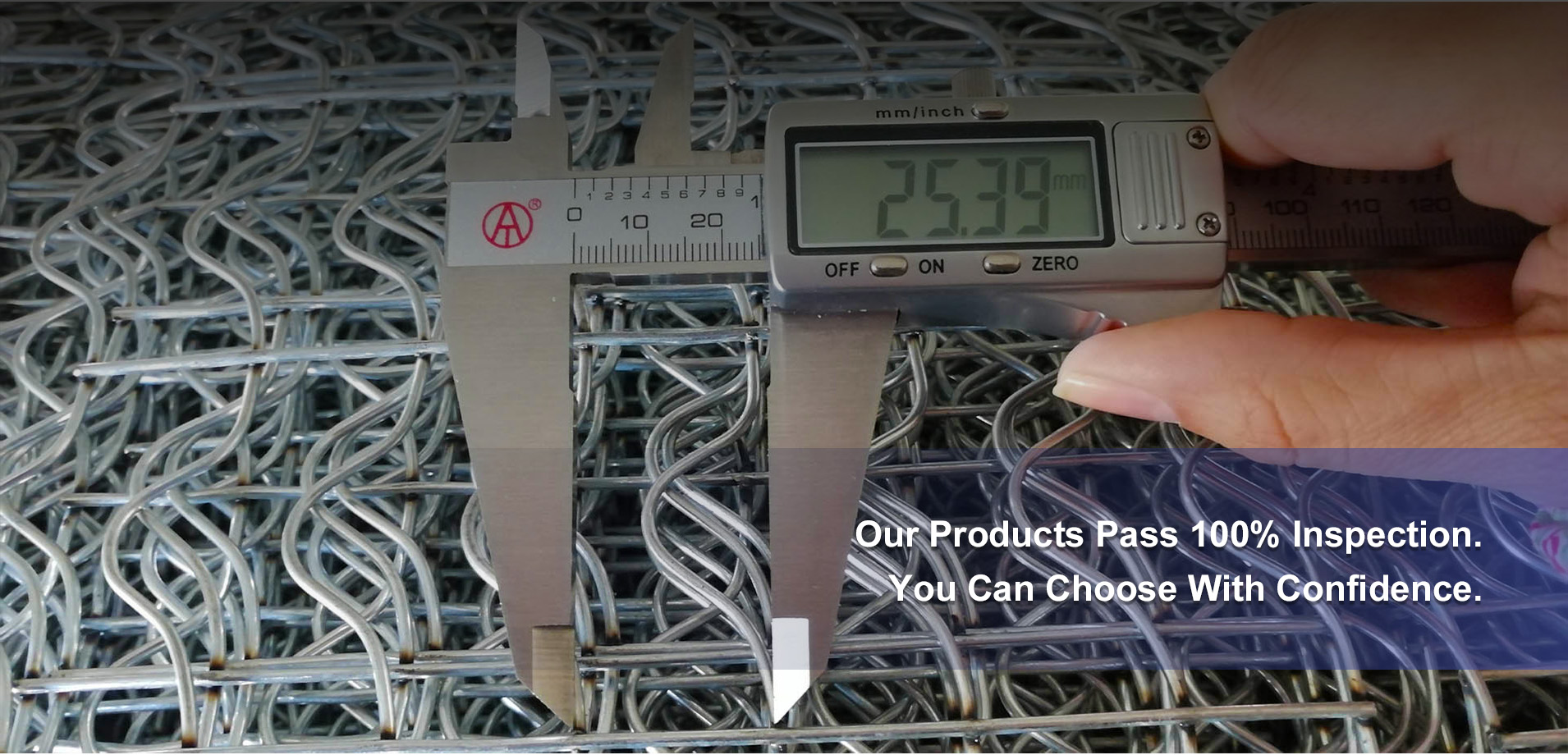

- Thickness Ranges from 1/8 inch (3.2mm) to 1 inch (25.4mm). - Spacing The distance between bearing bars often ranges from 1 inch (25.4mm) to 1.5 inches (38.1mm). - Width and Length Commonly available dimensions might include widths of 24 inches (610mm) and lengths of 36 inches (914mm), but larger sheets may measure 48 inches (1219mm) by 96 inches (2438mm).

These dimensions allow manufacturers to produce standardized products that can be used in a variety of applications, while custom sizes can be tailored as needed for specific projects.

Applications of Steel Grating

Steel gratings have numerous applications across various industries. Here are a few examples

steel grating standard sizes

2. Stair Treads and Landings They are often used for making stair treads because of their slip-resistant properties, which enhance safety in high-traffic areas.

3. Platforms and Walkways Steel gratings are ideal for outdoor walkways in parks or industrial yards, allowing for easy drainage and reducing standing water, thereby minimizing hazards.

4. Drainage and Gutter Covers In urban planning, steel gratings serve as durable covers for gutters and drains, ensuring that debris does not clog the systems while allowing water to flow freely.

5. Maintenance Access They are used in maintenance areas and access points for machinery, where easy visibility and airflow must be maintained.

Selecting the Right Size

When choosing the appropriate size of steel gratings, several factors need to be considered

- Load Requirements The weight the grating needs to support is crucial. Heavier loads may require thicker or more closely spaced bearing bars. - Environmental Conditions Areas prone to corrosive elements may necessitate a different steel grade or coating. - Traffic Type High traffic areas often require thicker gratings, while low foot-traffic areas may utilize thinner standard sizes.

- Installation Location The placement in either an outdoor or indoor environment can also dictate the size and type of grating to be used.

Conclusion

Understanding the standard sizes for steel gratings is vital for their effective application in various industries. By adhering to these specifications, companies can enhance efficiency, safety, and durability in their projects. As the demand for versatile and robust construction materials grows, the importance of ensuring compatibility through standardization becomes ever more critical. Remember, choosing the right size not only upholds safety standards but also optimizes performance, making it imperative for project managers and engineers to stay informed about these guidelines.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025