- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

steel grating span tables

Understanding Steel Grating Span Tables A Comprehensive Guide

Steel grating is a widely used industrial material known for its durability, strength, and versatility. It consists of a series of intersecting steel bars that form a grid, creating a surface that allows light, air, and water to pass through while providing support for heavy loads. In various applications, from walkways and platforms to drainage covers and grates, the design and load-bearing capabilities of steel grating are crucial. One essential tool in ensuring the proper use of steel grating is the span table.

What Are Span Tables?

Span tables are reference tools that provide critical information about the load-bearing capacity of steel grating over specific distances. They outline the maximum distance that steel grating can span between supports while maintaining safety and structural integrity under defined load conditions. These tables consider various factors, including the type of material, the thickness of the grating, and the anticipated load — whether it be a live load (people, equipment) or a dead load (the weight of the grating itself).

Key Factors in Span Table Calculations

1. Load Types Span tables address both live loads, which can vary based on usage, and dead loads, which are static and constant. Understanding the difference helps in choosing the appropriate grating for a specific application.

2. Grating Depth and Thickness The depth and thickness of the steel bars in the grating significantly influence its load capacity. Thicker and deeper grating can typically span longer distances and support heavier loads.

3. Material Grade Different grades of steel (such as carbon steel, stainless steel, or aluminum) will have varying strengths and corrosion resistance, which directly affects the overall performance of the grating.

steel grating span tables

4. Support Conditions The configuration of the supports will also affect span capabilities. For example, grating supported on both ends will have different span limitations than grating installed non-continuously.

Application of Span Tables

When planning installations, engineers and designers can use span tables to determine the appropriate grating type and dimensions for their specific needs. For instance, if a walkway requires a steel grating that spans a 5-foot distance and bears a load of 250 pounds per square foot, consulting the span table will reveal whether a certain grating cross-section can safely handle that situation.

Safety Considerations

Using proper span tables not only ensures structural integrity but also enhances safety for anyone using the gritted surface. Incorrectly sized or unsupported grating can lead to catastrophic failures, resulting in injuries or accidents. Consequently, adherence to span table guidelines is crucial in industrial design and construction.

Conclusion

In summary, steel grating span tables are vital resources for engineers and contractors, helping to ensure that installations are both safe and efficient. By understanding the parameters outlined in these tables—such as load types, material properties, and support conditions—designers can make informed decisions that enhance the functionality and safety of their projects. Investing time in consulting span tables can lead to better performance, longevity, and safety in the use of steel grating in various applications. Ultimately, whether for industrial use or architectural purposes, referring to steel grating span tables is essential for achieving a robust and reliable design.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

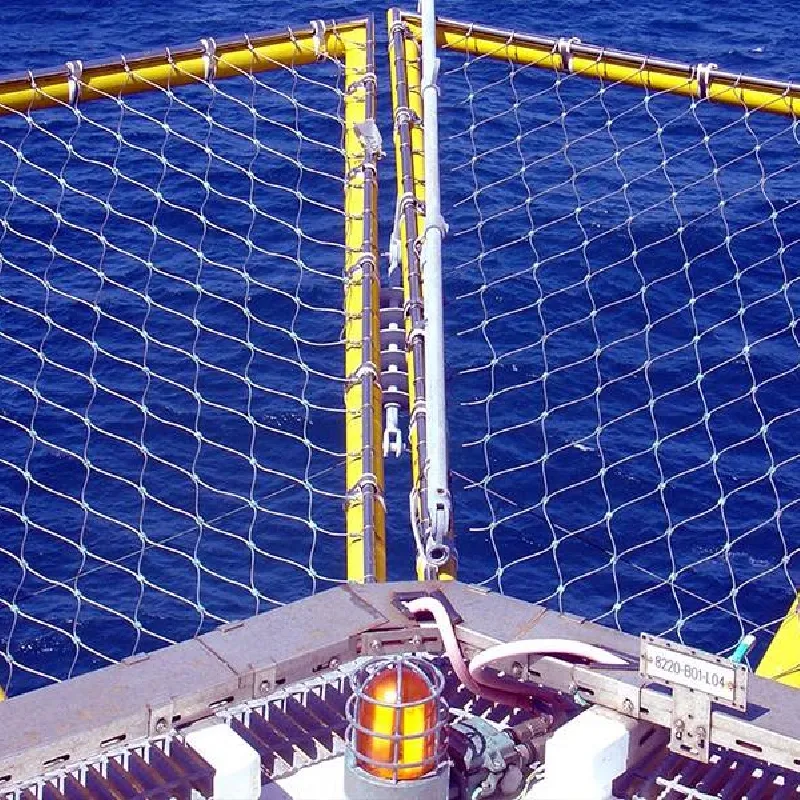

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025