- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

steel grating span tables

Understanding Steel Grating Span Tables A Comprehensive Guide

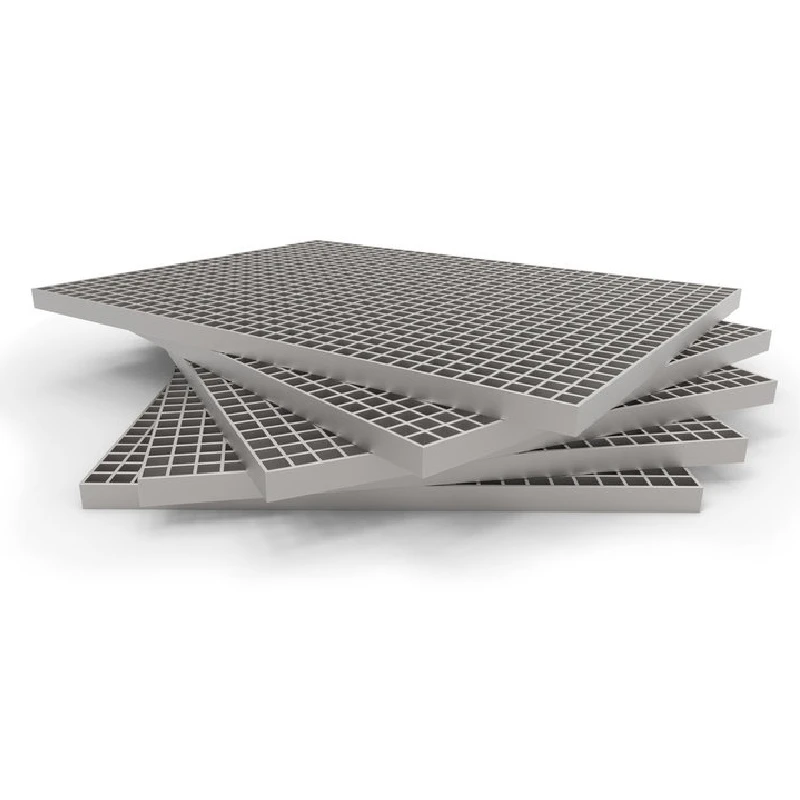

Steel grating is a widely used material in various industries due to its strength, durability, and versatility. It serves as a walking surface in industrial environments, walkways, catwalks, and other applications that require robust flooring solutions. An essential aspect of utilizing steel grating effectively is understanding the span tables associated with it. These tables provide critical information regarding the load-carrying capacity and spacing requirements of steel grating, ensuring safety and structural integrity in construction projects.

What are Steel Grating Span Tables?

Span tables for steel grating outline the maximum distance between supports for different types of grating materials and configurations, considering various load conditions. These tables typically include parameters such as the type of grating (e.g., pressed, welded, or swage-lock), load ratings (light, medium, heavy), and the dimensions of the grating sections. The information presented helps engineers, architects, and builders make informed decisions when selecting grating for their specific applications.

Importance of Understanding Span Tables

Utilizing steel grating span tables is crucial for several reasons

1. Safety The primary purpose of span tables is to ensure that the grating system can support the expected loads without failure. Understanding the limits set by the tables helps prevent accidents and injuries in industrial settings.

2. Regulatory Compliance Many construction projects must adhere to strict building codes and regulations. Familiarity with span tables enables professionals to select materials that meet these requirements, thereby avoiding legal complications.

3. Cost Efficiency Properly assessing the load capacities and spacing can lead to cost savings. Over-engineering can lead to unnecessary expenses, while under-engineering can result in structural failure and costly repairs. Span tables allow for a balanced approach to material selection.

Factors Influencing Span Table Selection

When navigating steel grating span tables, various factors should be considered

- Load Type Span tables categorize loads into static and dynamic. Understanding whether the grating will bear static weight (like machinery or personnel) or dynamic loads (like moving vehicles or equipment) is essential for accurate calculations.

steel grating span tables

- Environmental Conditions The setting plays a significant role in material selection. Gratings exposed to corrosive environments may require different specifications than those used in indoor applications. For example, stainless steel or galvanized options may be preferred in corrosive settings.

- Foot Traffic and Usage The expected foot traffic and usage patterns influence the choice of grating. Areas expecting high pedestrian traffic may require closer support spacing compared to less frequented zones.

Key Components of Span Tables

Steel grating span tables commonly highlight the following components

- Effective Span This refers to the distance between the supports, which determines the load-carrying capacity.

- Load Ratings Grating is assigned to different load categories, indicating how much weight it can safely support. These ratings help distinguish between light-duty, medium-duty, and heavy-duty applications.

- Panel Dimensions The size of the steel grating panels, including their thickness and spacing between the bars, affects the overall load capacity and durability.

- Support Spacing Recommended spacing between supports is critical for ensuring adequate support for the grating under varying loads.

Conclusion

Steel grating span tables are indispensable tools that enhance safety, compliance, and cost-effectiveness in construction projects. By understanding the key factors influencing selection and the critical components of these tables, engineers and stakeholders can make informed choices that meet their specific needs.

As industries continue to rely on steel grating for various applications, the importance of proper design practices and adherence to span tables will only grow. Continuous education and awareness of best practices in the selection and installation of steel grating can lead to more efficient, safe, and durable outcomes in industrial environments.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025