- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

steel grating price

Understanding Steel Grating Prices Factors That Influence Cost

Steel grating has become a popular choice in various industrial and commercial applications due to its durability, strength, and versatility. It is frequently used for walkways, platforms, stair treads, and drainage covers, among other uses. As demand for steel grating continues to grow, understanding how prices are determined is crucial for both buyers and sellers. This article will explore the factors that influence steel grating prices, helping you make informed purchasing decisions.

1. Material Quality

The quality of the steel used to manufacture the grating is one of the most significant factors affecting its price. Steel can vary in grade, thickness, and finish, each of which impacts the cost. Higher-grade steel, such as stainless steel or galvanized steel, generally comes at a premium due to its enhanced corrosion resistance and strength. Conversely, lower-grade steels may be less expensive but may not withstand harsh environmental conditions over time, leading to higher long-term costs due to maintenance or replacement.

2. Grating Type

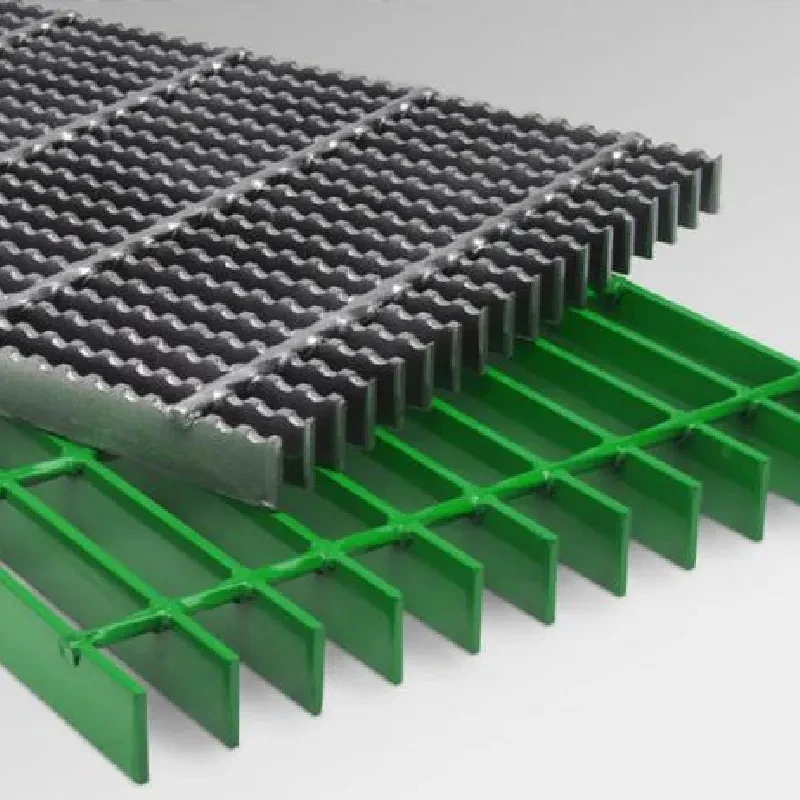

There are various types of steel grating available in the market, including welded steel grating, press-locked grating, and swage-locked grating. Each type has its own manufacturing process and application suitability, which can affect price. For instance, welded steel grating is typically more robust and durable than its press-locked counterpart, often resulting in a higher price point. Understanding your specific application requirements will help you determine which type offers the best value for your investment.

3. Size and Dimensions

The dimensions of the steel grating required for a project also play a crucial role in determining the price. Standard sizes may be more affordable due to economies of scale in manufacturing, while custom sizes often incur additional costs. Larger grates require more material and labor to produce and transport, leading to higher overall costs. When planning your project, it's advisable to measure carefully and consider standard sizes to optimize your budget.

steel grating price

Surface finish is another important factor that influences the price of steel grating. Various finishes, such as hot-dip galvanizing, electro-polishing, and powder coating, enhance the grating's aesthetics and corrosion resistance. While these finishes add to the initial costs, they can provide significant long-term savings by extending the lifespan of the grating. Businesses operating in corrosive environments, such as chemical plants or coastal areas, may find that investing in a higher-quality surface finish is worth the upfront expense.

5. Production Volume

The production volume also impacts pricing. Bulk orders often benefit from volume discounts, reducing the price per unit. If your project requires a large amount of steel grating, purchasing in bulk can lead to significant savings. However, smaller orders may face higher per-unit costs due to the fixed costs associated with production and logistics. It is important to evaluate the needs of your project and consult with suppliers about potential discounts for large orders.

6. Lead Time and Supply Chain Factors

Lead time and supply chain factors can dramatically affect steel grating prices. Global events, such as supply chain disruptions, tariffs, or raw material shortages, can lead to fluctuating prices. It's essential to stay informed about market trends and potential economic shifts that might impact availability and costs. Additionally, longer lead times can sometimes necessitate expedited shipping, further increasing costs.

7. Supplier Reputation

Finally, the reputation and reliability of the supplier can also influence pricing. Established suppliers with a strong track record of quality and service may charge a premium compared to lesser-known vendors. However, opting for a reputable supplier can lead to better customer service, warranties, and overall satisfaction. Investing in quality from a reputable provider can save you from the pitfalls of unreliable products.

Conclusion

Understanding the factors that influence steel grating prices can help you make informed purchasing decisions. Material quality, grating type, size, surface finish, production volume, lead time, and supplier reputation are all important considerations in determining the best value for your specific application. By carefully evaluating these factors and aligning them with your project needs, you will be well-equipped to navigate the steel grating market efficiently. Whether you are a contractor, a facility manager, or an architect, being knowledgeable about pricing dynamics ensures that you secure the best product for your investment.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025