- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

steel grating plate

Understanding Steel Grating Plates An Overview

Steel grating plates are an essential component widely used in various industries, owing to their strength, durability, and versatility. These structures are not merely an asset for industrial applications; they also enhance safety, provide efficient drainage, and create aesthetically pleasing environments. In this article, we will delve into the definition, applications, benefits, and manufacturing process of steel grating plates, shedding light on why they have become a staple in construction and engineering.

What are Steel Grating Plates?

Steel grating plates are flat steel structures that consist of a series of parallel bars or rods welded together. The bars are spaced apart to allow for the passage of air, light, or liquids while supporting foot traffic and heavy machinery. Commonly made from carbon steel, aluminum, or stainless steel, the type of material used often depends on the application and environmental conditions.

Applications of Steel Grating Plates

The applications of steel grating plates are extensive and diverse

1. Industrial Flooring In factories, warehouses, and other industrial settings, steel grating plates serve as durable flooring solutions. They can withstand heavy loads and are resistant to wear, making them ideal for environments with active foot and machine traffic.

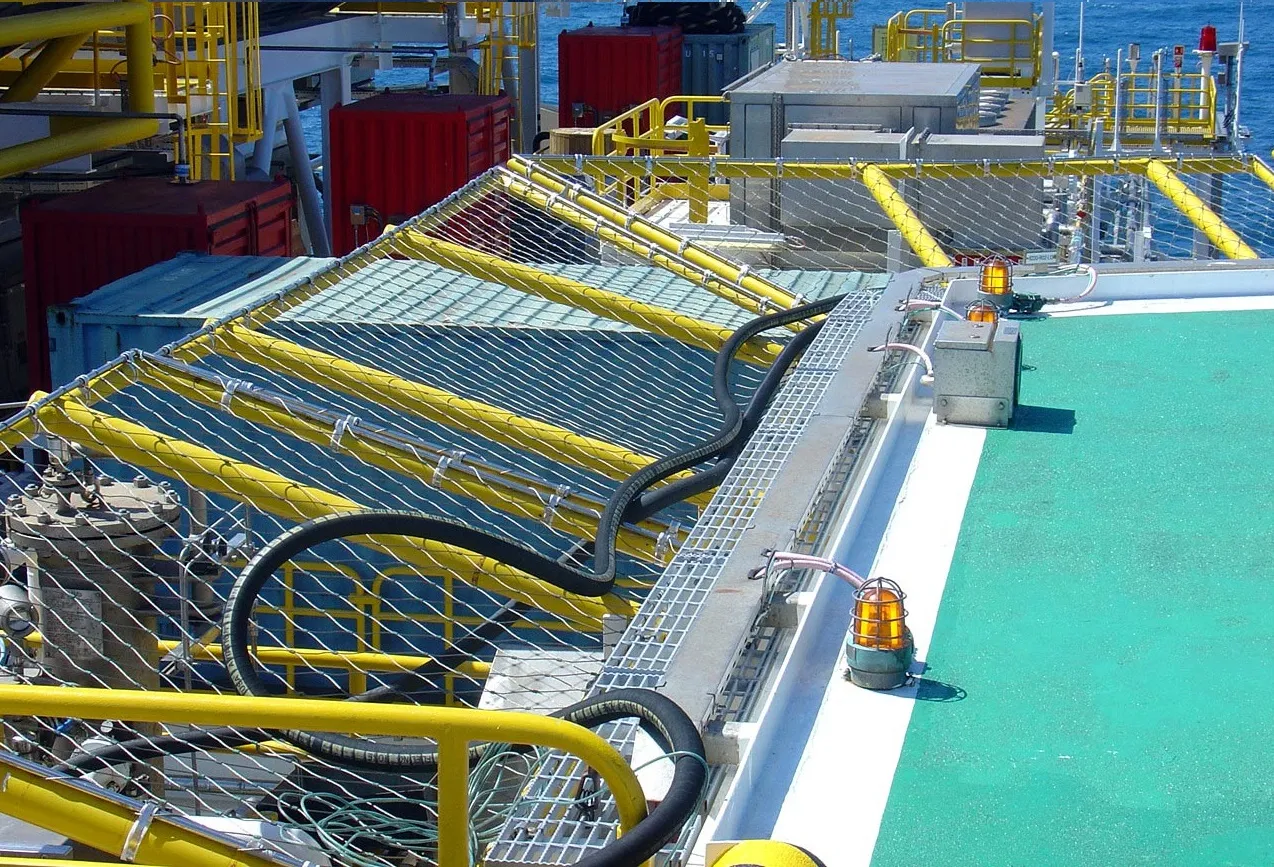

2. Walkways and Platforms Grating plates are frequently used to create walkways and platforms in various industries, including oil and gas, mining, and chemical plants. Their design allows for efficient drainage of water and chemicals, reducing the risk of slipping hazards.

3. Drainage Covers Steel grating plates are perfect for drainage applications, as they allow water to flow through while keeping debris out. These are commonly found in roadways, parking lots, and commercial premises where efficient drainage is necessary.

4. Safety Barriers They can be utilized as safety barriers in construction sites, ensuring that workers remain safe while providing a robust framework for additional safety features.

5. Architectural Purposes Beyond industrial uses, steel grating plates are also employed in architectural designs for both functional and aesthetic enhancements. They can be used in building facades, railings, and even in artistic installations.

Benefits of Steel Grating Plates

Choosing steel grating plates comes with a multitude of benefits

steel grating plate

1. Strength and Durability Steel is known for its exceptional strength-to-weight ratio, making grating plates capable of enduring heavy loads while remaining lightweight and easy to handle.

2. Corrosion Resistance Depending on the material used, particularly stainless steel, grating plates can resist corrosion and rust. This characteristic is crucial in environments exposed to chemicals or harsh weather conditions.

3. Ease of Maintenance Steel grating plates require minimal maintenance due to their robust design. Regular cleaning can suffice to keep them in excellent condition without needing frequent replacements.

4. Customizability Steel grating plates can be easily customized to meet specific dimensions and load requirements. They can also be coated or treated with additional finishes to enhance their properties.

5. Safety Features The open design of grating plates prevents the accumulation of water and debris, significantly reducing slip hazards. Furthermore, they provide excellent visibility, allowing for easy identification of hazardous areas.

Manufacturing Process of Steel Grating Plates

The manufacturing of steel grating plates involves several steps

1. Material Selection The first step involves selecting the appropriate steel type based on the intended application.

2. Cutting and Forming Steel sheets are cut into specific sizes and shapes before the bars are formed, depending on the grating design.

3. Welding The bars are then welded together to create a strong and stable structure. Various welding techniques are employed to ensure that the joints are robust and can handle significant loads.

4. Finishing After assembling, grating plates undergo surface treatment, which may include galvanizing, painting, or applying protective coatings to enhance corrosion resistance.

5. Quality Inspection Finally, each grating plate is inspected for quality, ensuring it meets industry standards and is ready for installation.

In conclusion, steel grating plates are a fundamental component across many sectors, providing safety, strength, and efficiency. Their diverse applications, coupled with numerous benefits, underscore their significance in modern industrial and architectural projects. As industries evolve, the demand for innovative and reliable solutions like steel grating plates will continue to grow, solidifying their role in the future of construction and design.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025