- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

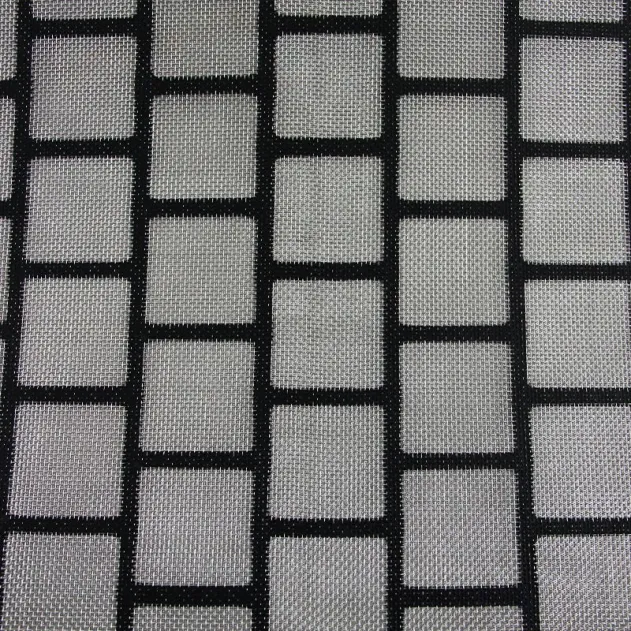

steel grating galvanis

Steel Grating Galvanization A Comprehensive Overview

Steel grating has become a cornerstone material in various industries due to its durability, strength, and versatility. Widely used in construction, infrastructure, and industrial applications, steel grating provides a high level of safety and performance. However, to enhance its lifespan and maintain its integrity under harsh conditions, galvanization has emerged as an essential process. This article delves into the significance, methods, and benefits of galvanizing steel grating.

What is Galvanization?

Galvanization is the process of applying a protective zinc coating to steel or iron, which serves as a barrier against corrosion. Steel grating, exposed to moist and corrosive environments, can suffer from rust and degradation if not adequately protected. Galvanization provides a long-lasting solution to this issue, making it an optimal choice for various applications, from industrial facilities to pedestrian walkways.

Methods of Galvanization

There are several techniques for galvanizing steel grating, the most common being

1. Hot-Dip Galvanization This process involves immersing clean steel grating in molten zinc at a temperature of around 450°C (842°F). The zinc adheres to the steel surface, forming a robust metallurgical bond. This method is favored for its comprehensive coverage, ensuring that even intricate designs and corners receive ample protection.

2. Electro-galvanization In electro-galvanization, a thin layer of zinc is applied to the steel surface through an electrochemical process. This method is often used for lighter applications where a lower level of corrosion resistance is acceptable. While it offers a smooth finish, it may not provide the same level of protection as hot-dip galvanization.

3. Zinc-rich Paint Another alternative is the application of zinc-rich paints, which contain a high percentage of zinc dust. While this method is less effective than traditional galvanization techniques, it can be suitable for touch-ups and smaller projects.

Benefits of Galvanized Steel Grating

The benefits of galvanizing steel grating are manifold, contributing to both the material's longevity and its performance

steel grating galvanis

2. Low Maintenance Galvanized steel grating requires minimal maintenance compared to unprotected steel, making it a cost-effective choice over time. Regular inspections are typically sufficient to ensure its continued performance.

3. Durability The coating provided by zinc is both hard and durable, protecting the underlying steel from physical damage, impact, and wear.

4. Safety In industrial and commercial settings, the safety of personnel is paramount. Galvanized steel grating offers a slip-resistant surface, reducing the risk of accidents in wet or oily environments.

5. Sustainability Zinc is a naturally occurring element, and the galvanization process allows for steel to be recycled without a significant loss in quality. This makes galvanized steel grating an environmentally friendly choice for infrastructure projects.

Applications of Steel Grating

With its numerous advantages, galvanized steel grating is utilized across various fields, including

- Walkways and Platforms Used in factories and outdoor settings, providing safe access while allowing debris and water to fall through. - Drain Covers Essential for maintaining proper drainage in urban settings, preventing blockages and the accumulation of water.

- Barriers and Fencing Offering security and visibility in industrial sites, galvanized steel grating is often employed in areas requiring both strength and aesthetics.

- Mining and Oil Industries Given their rugged environments, these industries heavily rely on galvanized steel grating for safe passage and support.

Conclusion

In summary, galvanized steel grating represents a resilient solution for various applications, combining the strength of steel with the protective qualities of zinc. Its corrosion resistance, durability, and low maintenance requirements make it an indispensable material in construction and industrial sectors. As the demand for sustainable and long-lasting materials continues to grow, galvanized steel grating is poised to remain a vital component in various infrastructures, ensuring safety and efficiency in the years to come.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025