- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Cost Analysis of Steel Grating for Construction Projects and Applications

Understanding the Costs Associated with Steel Grating

Steel grating is an essential component in various industrial and commercial applications, known for its strength, durability, and versatility. The cost of steel grating can fluctuate based on several factors, and understanding these variables is crucial for businesses and project managers planning to use this material. This article aims to provide insight into the various elements that influence the cost of steel grating, helping you make informed decisions for your projects.

Types of Steel Grating

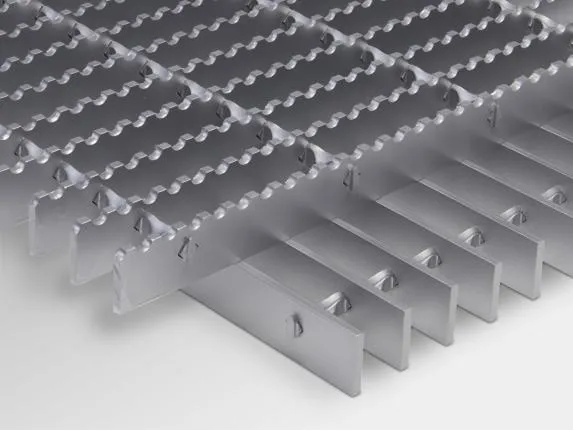

The first step in estimating the cost of steel grating is to understand the different types available in the market. The most common types of steel grating include

1. Bar Grating Made from flat steel bars that are welded or mechanically locked together. It offers high strength and is commonly used in walkways and platforms. 2. Expanded Metal Grating Created by cutting and stretching metal sheets, resulting in a unique diamond pattern. This type is lightweight and used in applications where drainage or ventilation is essential. 3. Perforated Grating Features holes punched into the material, providing a decorative appearance along with functional benefits like airflow and drainage.

Each type has its price point, influenced by the manufacturing process, materials used, and specific application requirements

.Material Costs

The material used in manufacturing grating significantly contributes to its overall cost. Steel prices can be volatile, influenced by market demand, availability, and global economic conditions. When the price of raw steel increases, so does the cost of finished grating products. Additionally, the grade of steel used—such as carbon steel, stainless steel, or galvanized steel—also impacts pricing. Higher-grade materials offer better corrosion resistance and longer life, which can justify a higher upfront cost.

Manufacturing Process

The manufacturing process of steel grating can also affect its price. Different fabrication methods, such as welding, forging, or casting, bear varying labor and machinery costs. For example, bar grating typically requires more complex manufacturing procedures, which can lead to higher costs compared to simpler expanded metal grating.

steel grating cost

Moreover, the customization of grating to meet specific project requirements—such as modified dimensions, specific load ratings, or special coatings—can increase manufacturing complexity and, consequently, cost.

Market Demand and Supply

The interplay of supply and demand plays a vital role in the pricing of steel grating. During construction booms or major infrastructure projects, the demand for steel products can surge, leading to increased prices. Conversely, during economic downturns, lower demand may result in decreased costs. Staying informed about market trends can help businesses schedule purchases strategically to maximize cost savings.

Additional Costs

When budgeting for steel grating, it’s important to consider additional costs beyond the base price of the grating itself. These can include

- Shipping and handling The cost to transport steel grating to your location can vary based on distance and transportation mode. - Installation Depending on the complexity of the installation process and labor rates in your area, installation costs can add significantly to the total expense. - Maintenance Over time, steel grating may require maintenance or replacement. The expected lifespan of the material should be factored into the overall cost assessment.

Conclusion

In summary, the cost of steel grating is influenced by a variety of factors, including the type of grating, material costs, manufacturing processes, market demand, and additional expenses associated with shipping, installation, and maintenance. Understanding these variables allows project managers and businesses to make more informed decisions that align with their budgets and project requirements.

When planning your next project involving steel grating, take the time to compare options and consult with suppliers to get the best value for your specific needs. By doing so, you can ensure that you’re making a sound investment in materials that will serve your project well for years to come.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025