- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

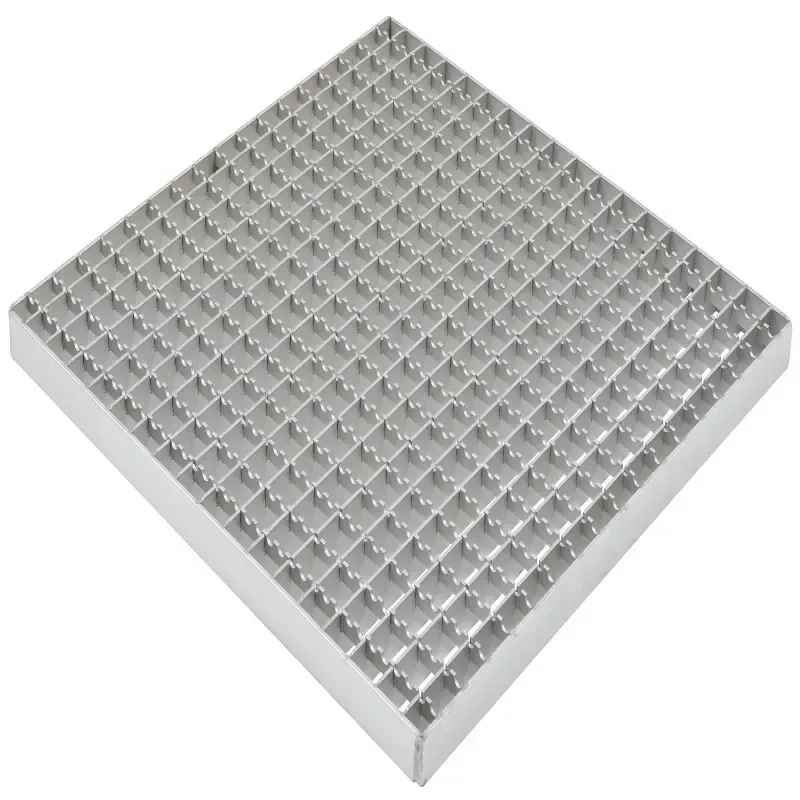

steel bar grating load tables

Understanding Steel Bar Grating Load Tables

Steel bar grating has become a critical component in various industrial and construction applications due to its durability, strength, and versatility. Among the essential tools for ensuring the effective use of steel bar grating are the load tables, which provide vital information to help engineers, architects, and designers make informed decisions regarding their applications.

Load tables typically specify the load capacities of different grating types, ranging from light-duty to heavy-duty applications. These tables indicate how much weight a particular grating can support, which is crucial when determining which type of grating to use for a given project. The information encompassed in these tables is derived from standardized tests that evaluate the performance of the grating under specific conditions.

When examining load tables for steel bar grating, several key factors need to be considered

1. Grating Material and Construction Steel is commonly used due to its strength and resistance to impact and wear. The type of steel—whether galvanized, stainless, or carbon—affects the overall durability and weight-bearing capacity.

2. Bearing Bar Spacing This refers to the distance between the bars that support the grating's surface. Typical spacing ranges from 1.5 inches to 4 inches. Closer spacing often increases load capacity, making it essential to align the grating specifications with the intended load.

steel bar grating load tables

3. Load Types Load tables will categorize loads into uniform loads (distributed evenly across the surface) and concentrated loads (point loads applied at a single location). For safety and structural integrity, it is crucial to understand the type of load the grating will encounter in its application.

4. Deflection Load tables also provide information on deflection under load, which is critical for ensuring safety and performance. Excessive deflection can lead to structural failures or safety hazards. Engineers often look for deflection limits that are acceptable according to building codes and safety regulations.

5. Span Length The span is the distance between two points of support for the grating. Understanding the appropriate span for different types of loads is essential for selecting the right grating to ensure both functionality and safety.

6. Environmental Factors For outdoor applications, resistance to corrosion is vital. Load tables may also indicate suitable coatings or galvanizing methods used to protect the steel from environmental wear and tear.

By utilizing steel bar grating load tables, engineers can design safer and more efficient systems. They can calculate the necessary type of grating for walkways, platforms, and other structures, ensuring that they meet relevant safety standards and performance expectations.

In conclusion, steel bar grating load tables serve as an invaluable resource for professionals in construction and engineering. Understanding the various parameters outlined in these tables allows for the proper selection of grating, thereby enhancing safety, efficiency, and longevity in various applications. As industries continue to evolve, familiarizing oneself with load tables ensures that best practices are upheld, ultimately contributing to safer infrastructures and better-designed spaces.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025