- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

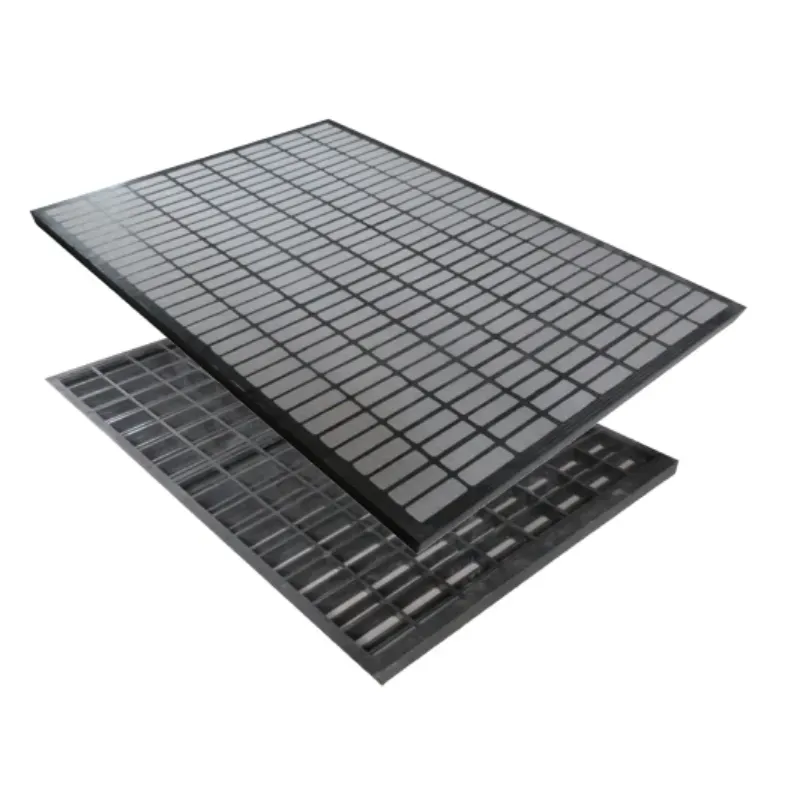

Steel Framing Shale Shaker Screens

When it comes to oil industry operations and drilling processes, efficiency and durability are paramount. One key component that plays a significant role in optimizing the drilling process is the shale shaker screen. A shale shaker screen helps separate solids from liquids in the drilling fluid, preventing the mixing of mud and ensuring smooth drilling operations. If you're looking for a shale shaker screen for sale, you might want to consider steel framing shale shaker screens that are specifically designed to provide exceptional performance and durability. Let’s explore how these screens can enhance your drilling process.

Why Steel Framing Shale Shaker Screens Are Essential

In the world of drilling, the shale shaker screen is responsible for separating solid particles from the liquid in the drilling fluid, allowing the reusable fluid to flow back into the system. Steel framing shale shaker screens are a vital part of this process due to their robustness and filtering capabilities.

The key advantage of steel framing is the increased strength it provides to the shaker screen. The steel support ensures that the screen can withstand the high pressures and stresses encountered during drilling operations. This strong steel framing is perfect for harsh conditions in the oil and gas industry, as it offers superior support, rigidity, and resistance to wear and tear.

In addition, the shale shaker screen mesh used in these screens is typically made from high-tensile stainless steel or other durable materials, making the overall product resistant to abrasion, corrosion, and high temperatures. This enhances the screen's longevity, ensuring that it performs reliably over long periods without the need for frequent replacements.

Superior Filtration with Shale Shaker Screen Mesh

The shale shaker screen mesh is a critical element in determining the efficiency of the screening process. Whether you're dealing with heavy drilling fluids or fine particulates, choosing the right shale shaker screen mesh can have a huge impact on your operation's success.

The mesh size and material composition of the shaker screen are designed to meet the specific requirements of your drilling operation. Steel framing shale shaker screens use woven mesh materials that allow for effective separation of drill cuttings from the fluid. These screens are designed with precision mesh, ensuring that the filtration process is highly efficient.

With the right mesh size, these screens can handle fine particulates, preventing the clogging of pumps and other critical equipment. This not only improves the efficiency of your drilling process but also reduces the need for frequent maintenance, leading to cost savings and reduced downtime.

Durability and Longevity of Shale Shaker Screens

In the drilling industry, downtime means loss of production, and one of the key ways to prevent that is by using high-durability shale shaker screens. Steel framing shale shaker screens are known for their strength, resilience, and long-lasting performance. The steel support ensures that the screens maintain their integrity even in the most demanding conditions.

Whether you're working in harsh oil drilling environments or other high-stress drilling conditions, these screens provide a reliable solution for solid-liquid separation. Shale shaker screens for sale made with steel framing can withstand the abrasive nature of the materials they filter, ensuring they don't degrade or break down under the pressure.

Additionally, the durability of these screens reduces the frequency of replacements, which translates to lower operational costs over time. The long lifespan of the shaker screens allows you to maximize your investment, making them a valuable asset to your drilling operations.

Choosing the Right Shale Shaker Screen for Sale

When it comes to purchasing shale shaker screens for sale, there are several factors to consider. Steel framing shale shaker screens offer superior durability, but it’s important to ensure the screen's specifications match your operation's needs.

- Material Quality: The best shaker screens are made from high-quality materials, such as stainless steelor composite materials, which offer superior strength and resistance to corrosion.

- Mesh Size: Choose a mesh size that suits the type of solids you need to separate. The right mesh size ensures that the fluid remains clean and free from particulates.

- Screen Type: There are various types of shaker screens, such as woven meshand composite frame screens, so consider which one will provide the most efficient filtration for your drilling process.

- Cost: While quality should always be a priority, it’s also essential to choose a shale shaker screen for salethat fits your budget while offering durability and performance.

By selecting the right shale shaker screen mesh and considering the steel framing features, you can ensure your drilling operation runs smoothly, improving efficiency and reducing downtime.

Why Choose Our Shale Shaker Screens for Sale?

As a leading supplier of shale shaker screens, we provide steel framing shale shaker screens that are specifically engineered to offer the highest quality and performance in the oil and gas industry. Our screens are built with high-tensile mesh and strong steel support, ensuring maximum durability and efficiency.

With our shale shaker screens for sale, you can benefit from:

- Long-lasting durability: Made from the best materials to ensure your screen can withstand harsh drilling environments.

- High filtration efficiency: Our screens are designed with precision mesh for effective solid-liquid separation.

- Reduced downtime: Thesteel framing ensures that our screens remain intact, reducing the need for frequent replacements and minimizing operational interruptions.

Explore our selection of shale shaker screens on our website today, and invest in high-quality equipment that will enhance the performance and efficiency of your oil industry drilling operations. Don’t settle for less — choose our top-tier shaker screens for reliable, long-lasting results!

-

The Versatility of Steel Walkway GratingNewsAug.07,2025

-

The Benefits of Galvanized Steel Grating for Your ProjectsNewsAug.07,2025

-

Shaker Screens: The Ultimate Solution for Your Drilling NeedsNewsAug.07,2025

-

Perimeter Safety Net: An Essential Solution for Helipad SafetyNewsAug.07,2025

-

Enhance Safety and Efficiency with Steel Walkway GratingNewsAug.07,2025

-

Discover Exceptional Steel Grating for SaleNewsAug.07,2025