- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

ss grating

Understanding SS Grating A Comprehensive Overview

In the realm of engineering and design, SS grating, or stainless steel grating, has emerged as a versatile and highly sought-after material used across various industries. This article delves into the characteristics, benefits, applications, and maintenance of SS grating, elucidating its significance in modern industrial settings.

What is SS Grating?

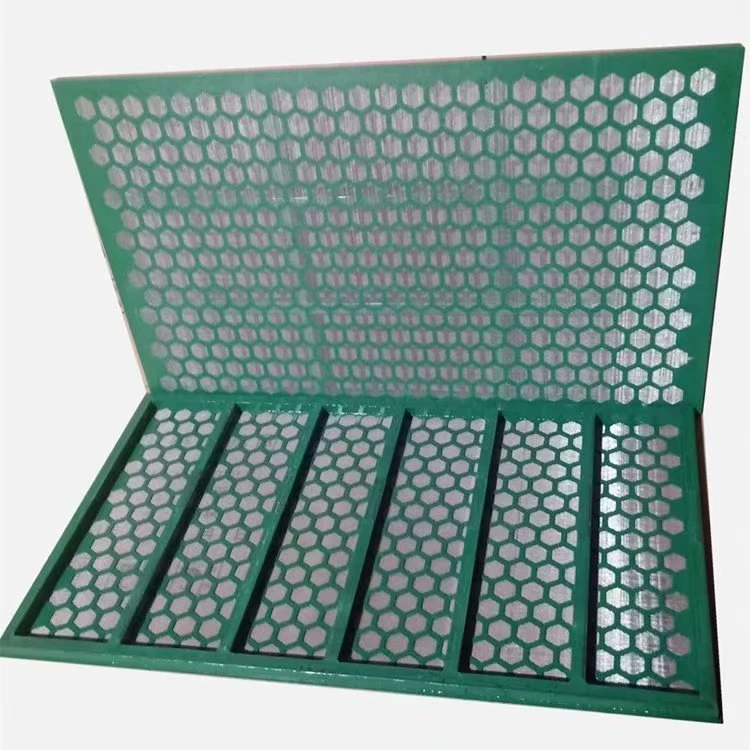

SS grating refers to a type of flooring or walkway material made from stainless steel, which is renowned for its durability, resistance to corrosion, and aesthetic appeal. Typically fabricated through a process of welding or press-locking, SS grating is available in various styles, including bar grating, expanded metal, and perforated sheets. The choice of design often depends upon the specific application and the load-bearing requirements.

Characteristics of SS Grating

1. Corrosion Resistance One of the primary advantages of SS grating is its exceptional resistance to corrosion, making it suitable for harsh environments, such as chemical plants, waste treatment facilities, and coastal applications where exposure to moisture and salt is prevalent.

2. Strength and Durability Stainless steel boasts impressive tensile strength, allowing SS grating to support substantial weight loads without deformation. This resilience extends the lifespan of the infrastructure, reducing the need for frequent replacements.

3. Safety Features Many SS grating options come with features such as slip resistance and visibility enhancements. This is particularly vital in industrial settings where worker safety is paramount. The open slots in the grating facilitate drainage and reduce the accumulation of liquids, further minimizing slip hazards.

4. Aesthetic Appeal Stainless steel has a modern and sleek appearance, making SS grating a preferred choice in architectural applications. It can enhance the visual appeal of commercial buildings, shopping centers, and walkways while providing robust functionality.

Applications of SS Grating

ss grating

SS grating finds its applications in numerous sectors

- Industrial Facilities Commonly utilized in factories, warehouses, and processing plants for flooring, access platforms, and walkways due to its strength and safety features.

- Marine and Coastal Environments Its corrosion resistance makes it ideal for use in docks, piers, and marine infrastructure.

- Commercial Buildings Used in architectural facades and decorative elements, SS grating adds aesthetic value while serving functional needs.

- Wastewater Treatment SS grating is often used in treatment plants to create walkways and platforms that endure harsh chemicals and wet conditions.

Maintenance of SS Grating

Maintaining SS grating is relatively straightforward, primarily due to the inherent properties of stainless steel. Regular inspection is essential to identify any signs of wear, corrosion, or other damage. Cleaning can typically be accomplished with water and mild detergents, and for particularly tough stains, a power washer may be used. It is also advisable to avoid using abrasive materials or harsh chemicals that might damage the surface.

Conclusion

In summary, SS grating is an exemplary material that combines functionality, durability, and aesthetic appeal. Its unique properties make it invaluable in various fields, from industrial and marine to commercial applications. As industries continue to evolve and prioritize safety and sustainability, the relevance of SS grating is only expected to grow. Embracing the advantages offered by this material can lead to enhanced structural integrity and improved safety standards in any setting.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025