- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Exploring the Applications and Benefits of SS 304 Grating in Various Industries

Understanding the SS304 Grating Features, Applications, and Benefits

Stainless steel has become a favored material in various applications due to its strength, durability, and resistance to corrosion. Among its various forms, SS304 grating stands out as a highly versatile and effective solution tailored for different industries. This article delves into the features, applications, and benefits of SS304 grating, emphasizing why it is widely used in commercial and industrial environments.

Features of SS304 Grating

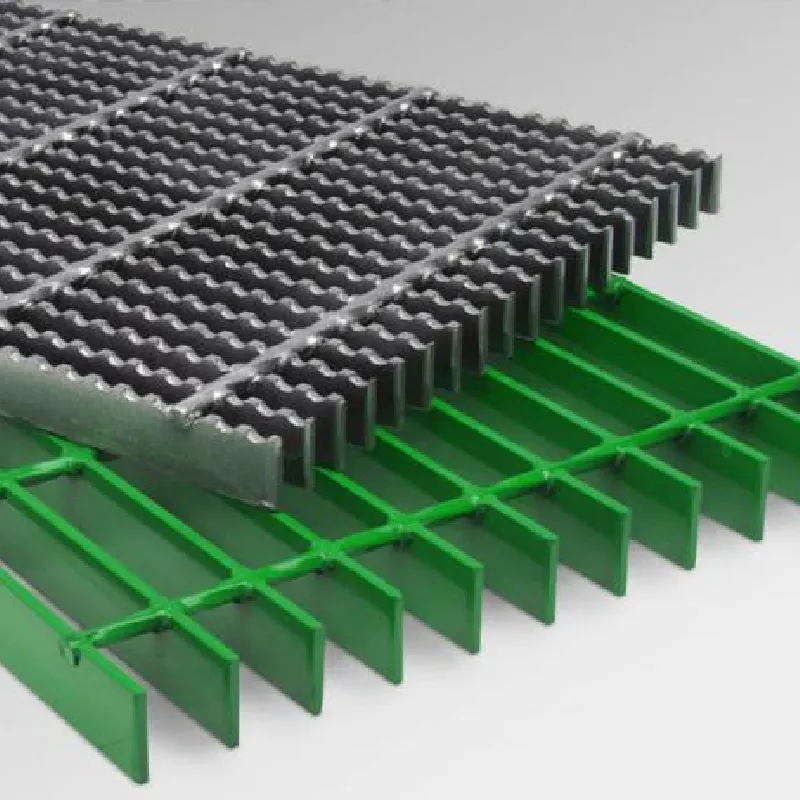

SS304 grating is predominantly made from stainless steel type 304, which contains a blend of 18% chromium and 8% nickel. This combination ensures that the material exhibits exceptional resistance to corrosion and oxidation, making it suitable for both indoor and outdoor applications. The grating comes in various designs, including welded, pressure-locked, and swage-locked, allowing for customization based on load requirements and environmental conditions. The open design of SS304 grating enables efficient drainage and ventilation while providing excellent slip resistance, making it safer for heavy foot traffic.

Another notable feature of SS304 grating is its strength-to-weight ratio. Despite being lightweight, SS304 exhibits high tensile strength, enabling it to support heavy loads without bending or warping. This characteristic makes it a preferred option for flooring, walkways, and platforms in industrial settings. Additionally, SS304 grating can withstand extreme temperatures, making it suitable for applications in food processing, chemical industries, and even marine environments.

Applications of SS304 Grating

Due to its beneficial properties, SS304 grating finds a wide array of applications across various sectors. In the construction and architectural field, it is commonly utilized for flooring, stair treads, and safety railings. The aesthetic appeal of stainless steel grating, combined with its functionality, enhances the overall design of commercial spaces.

In industrial settings, SS304 grating is often employed in platforms, walkways, and drainage systems. Its ability to resist corrosive substances makes it ideal for factories and warehouses handling chemicals and other hazardous materials. Moreover, its easy maintenance and cleaning capabilities add to its appeal for those in food processing environments, where hygiene is of utmost importance.

ss 304 grating

The marine industry also benefits from SS304 grating. It’s used in shipbuilding and offshore platform construction, where exposure to saltwater can significantly impact the integrity of materials. Its corrosion resistance ensures longevity and reliability in such challenging environments.

Benefits of SS304 Grating

One of the significant benefits of SS304 grating is its longevity. With proper maintenance, it can last for decades, which reduces the need for frequent replacements and lowers overall costs. Additionally, the low maintenance requirement of stainless steel grating means fewer resources are spent on upkeep, allowing businesses to allocate their budgets more efficiently.

The ease of installation is another advantage. SS304 grating is lightweight and comes in pre-fabricated sizes, facilitating quick and easy installation, whether for new projects or renovations. This characteristic is particularly valuable in time-sensitive projects where minimizing downtime is crucial.

In terms of sustainability, SS304 can be recycled without degrading its properties, making it an environmentally responsible choice for businesses looking to reduce their carbon footprint.

Conclusion

SS304 grating is a prime example of the advantages that stainless steel can offer across various applications. Its strength, corrosion resistance, and versatility make it an ideal choice for numerous industries, from construction and food processing to marine applications. Investing in SS304 grating not only enhances safety and efficiency but also contributes to long-term sustainability, making it a leading choice for contemporary projects.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025