- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

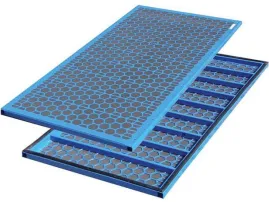

shale shaker screens for sale

Shale Shaker Screens for Sale Essential Tools for the Oil and Gas Industry

In the oil and gas industry, particularly in drilling operations, shale shaker screens play a crucial role in the separation of solids from drilling fluids. These screens are integral components of shale shakers, which are machines that filter out unwanted materials from the drilling fluid before it is recirculated back to the drilling process. If you're in the market for shale shaker screens, understanding their varieties, features, and suppliers can help you make an informed decision.

Understanding Shale Shaker Screens

Shale shaker screens come in various types and sizes, tailored to meet the specific requirements of different drilling operations. They are primarily categorized based on their mesh size, material, and construction. The most common types include flat, pyramid, and linear screens, each designed to optimize the screening process for various conditions and types of drilling fluid.

The mesh size is a critical factor that determines the screen's performance. Finer meshes are capable of filtering out smaller particles, while coarser screens allow for faster fluid flow but may not remove all sediments. Thus, selecting the right mesh size is vital to enhance the efficiency of the drilling operation and the life span of the equipment.

Materials and Durability

shale shaker screens for sale

Shale shaker screens are generally made from durable materials such as stainless steel or composite synthetic materials. Stainless steel screens are known for their strength and resistance to wear and corrosion, making them an ideal choice for harsh drilling conditions. On the other hand, synthetic screens, though possibly less durable in extreme conditions, often provide better separation efficiency and are lighter, which can be advantageous in certain applications.

Finding Shale Shaker Screens for Sale

When looking for shale shaker screens for sale, it's essential to consider several factors, including the supplier's reputation, product quality, and after-sales support. Numerous manufacturers and suppliers specialize in drilling equipment and offer a wide range of shale shaker screens. Online marketplaces, industry trade shows, and specialized distributors can also provide options.

Selecting a reliable supplier ensures that you receive high-quality screens that meet industry standards. Look for suppliers who offer warranties, after-sales services, and technical support, as these can make a significant difference in the operational effectiveness and maintenance of your drilling equipment.

Conclusion

Investing in high-quality shale shaker screens is crucial for the success of any drilling operation in the oil and gas industry. Not only do they enhance the efficiency of the drilling mud recycling process, but they also contribute to the overall effectiveness and safety of the operation. By understanding the various types of screens, their materials, and where to find them for sale, operators can improve their drilling processes and achieve better results. As the industry evolves, staying updated on advancements in shale shaker technology and screen designs will continue to be essential for optimizing drilling performance and reducing operational costs.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025