- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

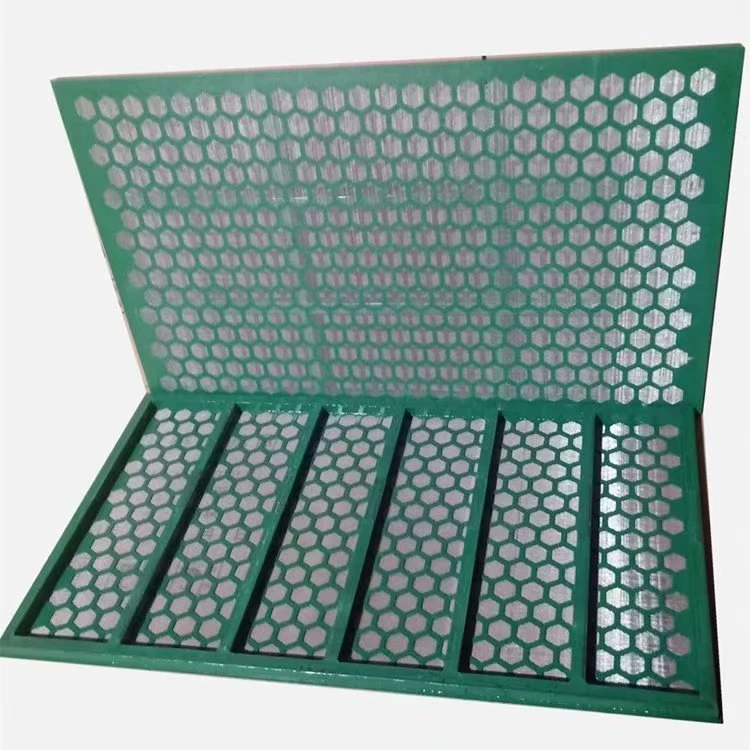

Effective Shale Shaker Screen Mesh Solutions for Optimal Drilling Performance and Efficiency

Understanding Shale Shaker Screen Mesh A Key Component in Drilling Operations

In the oil and gas industry, efficient drilling operations are crucial for maximizing productivity and minimizing costs. One critical component in the drilling process is the shale shaker screen mesh. This specialized equipment plays a vital role in separating the cuttings from drilling fluids, ensuring that the drilling process runs smoothly and effectively.

What is Shale Shaker Screen Mesh?

Shale shaker screen mesh is a screening medium used in shale shakers, which are devices designed to separate solids from liquids in the drilling fluid. The primary function of the shale shaker is to remove the drilled cuttings from the mud, allowing for the recycling and reuse of drilling fluid. The screen mesh acts as a filter, allowing the liquid to pass through while blocking larger solid particles.

Typically made from high-quality materials such as stainless steel or composite materials, shale shaker screens come in various mesh sizes. The mesh size determines the particle size that can pass through the screen and is crucial for maintaining the efficiency of the drilling operation. A finer mesh will filter out smaller particle sizes, while a coarser mesh allows larger particles to pass through.

Types of Shale Shaker Screen Mesh

There are several types of shale shaker screen mesh, each designed for specific applications and drilling conditions. The two main types are

1. Flat Screens These screens have a flat surface and are commonly used in traditional shale shakers. They are lightweight and easy to replace, making them a popular choice for many drilling operations.

2. Corrugated Screens These screens have a wave-like structure, which increases the surface area and enhances the separation process. They are typically used in high-volume drilling applications where the demand for solids control is greater.

Additionally, screens can be designed with different mesh sizes and configurations, such as T-duct or pyramid styles, to optimize the effectiveness of the solids removal process.

shale shaker screen mesh

Importance of Choosing the Right Mesh

Selecting the appropriate shale shaker screen mesh is essential for drilling efficiency. An incorrect mesh size can lead to various issues, including

- Inadequate Solids Removal Using a mesh that is too coarse may allow excessive cuttings to pass through, leading to poor hole cleaning and potential formation damage.

- Fluid Loss A mesh that is too fine may result in excessive loss of drilling fluid, increasing operational costs and affecting drilling performance.

- Screen Blinding If particles are too large for the chosen mesh, the screen can become clogged or blinded, reducing its effectiveness and requiring more frequent maintenance.

Maintenance and Replacement

Regular maintenance and timely replacement of shale shaker screen mesh are crucial for maintaining optimal drilling performance. Operators should monitor the condition of the screens and replace them as necessary to prevent compromise in the solids control process. Signs that a screen may need replacing include visible wear, holes, or blinding caused by built-up solids.

Conclusion

In summary, shale shaker screen mesh is an integral part of the drilling process in the oil and gas industry. Understanding the types of screens available, the importance of mesh selection, and the necessity for regular maintenance can significantly enhance drilling efficiency. By investing in high-quality shale shaker screens and following best practices for their use, operators can ensure a more effective and productive drilling operation, ultimately leading to better resource management and cost savings. As technology advances, the development of even more efficient mesh designs will continue to revolutionize the industry.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025