- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

shale shakerscreen manufacturers

Understanding Shale Shaker Screen Manufacturers

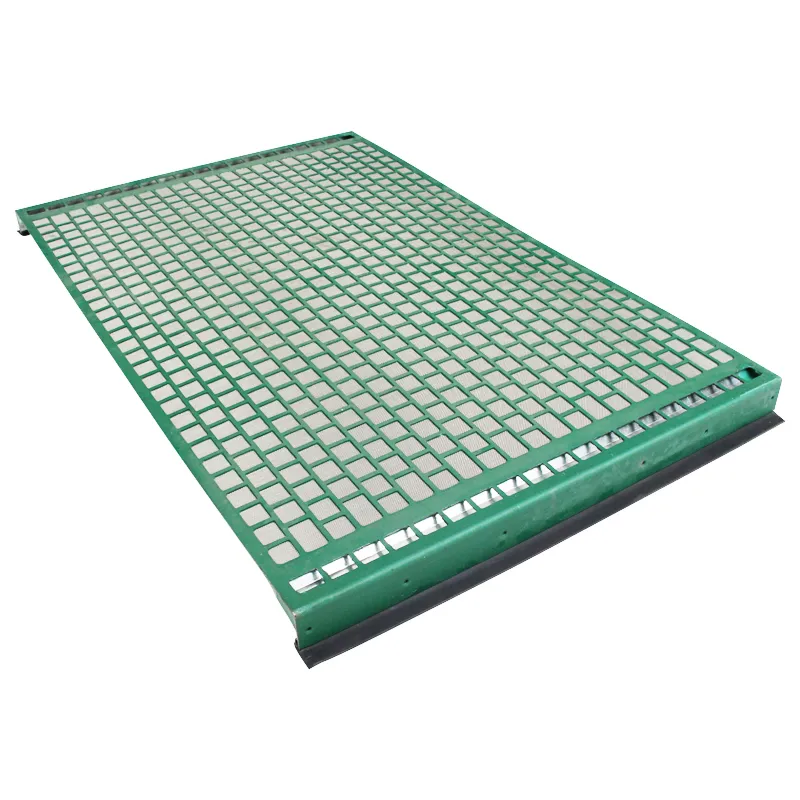

In the oil and gas industry, the extraction process is a complex one that involves numerous equipment pieces, one of the most crucial being the shale shaker. This equipment plays a pivotal role in the drilling process by separating cuttings from the drilling fluid, ensuring that the latter can continually be recycled. At the heart of this operation are shale shaker screens, manufactured by specialized companies that emphasize quality, durability, and performance.

Shale shaker screens are engineered to withstand extreme conditions and are subject to wear and tear due to their extensive use in harsh environments. Manufacturers of these screens must focus on developing products that not only meet industry standards but also exceed them to ensure the efficiency and effectiveness of the drilling operations. This leads us to consider what defines a leading shale shaker screen manufacturer.

Key Features of Leading Manufacturers

1. Material Quality The durability and performance of shale shaker screens heavily depend on the materials used in their construction. Reputable manufacturers often utilize high-quality stainless steel and specialized polymers that can withstand abrasive materials without compromising performance.

2. Customization Different drilling operations require screens with varied mesh sizes and designs. Top manufacturers offer customizable options that allow clients to choose screens tailored to specific drilling needs, enhancing operational efficiency.

3. Innovative Technology The best manufacturers are not only focused on the current state of the market but are also invested in research and development to create innovative products. This can include advancements in screen design that improve fluid flow and increase separation efficiency.

4. Certification and Compliance Leading manufacturers are typically certified by relevant industry standards, ensuring that their products meet strict quality and safety guidelines. This is essential not only for the performance of the screens but also for compliance with regulations.

5. Strong Customer Support Excellent customer service is a hallmark of reputable manufacturers. This includes offering guidance on screen selection, maintenance tips, and prompt responses to inquiries. A manufacturer that supports its clients helps foster long-term relationships, critical in the competitive oil and gas sector.

shale shakerscreen manufacturers

The Role of Technology in Manufacturing

In recent years, technological advancements have significantly impacted the shale shaker screen manufacturing process. Computer-aided design (CAD) software allows manufacturers to create precise designs that optimize performance. Additionally, automated production lines enable greater consistency in the quality of the screens produced.

Manufacturers also utilize rigorous testing methods to ensure each product meets high performance standards before reaching the market. This might include simulations of real drilling conditions to analyze how well the screens operate under pressure.

Market Trends

The market for shale shaker screens is poised for growth, driven by an increase in drilling activities worldwide. As countries seek to reduce their dependence on foreign oil, local oil fields are being tapped more extensively, resulting in higher demand for efficient drilling solutions. Additionally, the push towards sustainable practices means that manufacturers are focusing on producing screens that minimize environmental impact, aligning with global sustainability goals.

Choosing the Right Manufacturer

When selecting a shale shaker screen manufacturer, it is essential to do thorough research. Consider factors such as experience in the industry, client testimonials, and the range of products offered. It is also wise to compare warranties and service agreements, as these can be indicative of a manufacturer’s confidence in their products.

In conclusion, the role of shale shaker screen manufacturers is integral to the success of drilling operations in the oil and gas industry. By focusing on quality, innovation, and customer needs, leading manufacturers ensure that their products contribute to efficient and effective drilling processes while adapting to the evolving demands of the industry. As the market continues to expand, the importance of these manufacturers will only grow, making it crucial for industry players to choose their partners wisely.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025