- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

shale shaker screen for sale

Exploring Shale Shaker Screens for Sale A Comprehensive Guide

In the realm of oil and gas drilling operations, the efficiency of the process largely depends on the quality of the equipment used, particularly shale shaker screens. These screens play a crucial role in the separation of drilling fluids and solids, making them indispensable for optimal performance. As the demand for oil continues to rise, so does the need for high-quality shale shaker screens. In this article, we will explore the importance of shale shaker screens, the factors to consider when purchasing them, and available options for sale.

What are Shale Shaker Screens?

Shale shaker screens are essential components of shale shakers, which are used in the initial stages of the drilling process. These screens filter out the larger solids from the drilling mud, allowing the cleaner fluid to be reused in the drilling operation. Proper separation of solids enhances the efficiency and longevity of drilling equipment, thereby reducing operational costs.

Importance of Quality Screens

The quality of shale shaker screens directly impacts the overall efficiency of the drilling operation. High-quality screens ensure effective filtration and prevent clogging, which can lead to costly downtime. Additionally, the right screens can enhance mud circulation, resulting in better cooling and lubrication for the drill bit. Hence, investing in superior-quality screens is a key factor in maintaining a productive drilling operation.

Factors to Consider When Purchasing Shale Shaker Screens

When selecting shale shaker screens, there are several critical factors to consider

1. Material The materials used to construct the screens determine their durability and effectiveness. Common materials include steel and composite materials. Choose screens that are resistant to wear and tear, as they will be subjected to harsh operating conditions.

2. Mesh Size The mesh size refers to the number of openings per square inch. Depending on the type of solids to be filtered, selecting the appropriate mesh size is crucial. A finer mesh will capture smaller particles but may also lead to quicker clogging, while a coarser mesh may allow some solids to pass through.

3. Screen Type There are various types of shaker screens available, including flat screens, corrugated screens, and pyramid screens, each with distinct advantages in terms of flow rate and soil retention.

shale shaker screen for sale

4. Compatibility Ensure that the screens you select are compatible with your existing shaker unit. Manufacturers often provide specifications and compatibility details that can assist in making the right choice.

5. Ease of Installation and Maintenance Screens that are easy to install and maintain can save time and money. Look for user-friendly designs that facilitate quick changes and minimal downtime.

6. Manufacturer Reputation Choosing a reputable manufacturer can make a significant difference in the performance and longevity of shale shaker screens. Research brands and read customer reviews to find a trusted provider.

Finding Shale Shaker Screens for Sale

Shale shaker screens are widely available for sale across various platforms. You can find them through

- Online Suppliers Many manufacturers and suppliers offer their products online, providing detailed specifications, pricing, and customer support.

- Industry Trade Shows Networking at trade shows and industry events can be an excellent way to find reliable suppliers and learn about the latest innovations.

- Local Distributors Checking with local equipment distributors can sometimes yield quicker access to the required screens, as well as additional benefits like local support and advice.

Conclusion

Choosing the right shale shaker screens is integral to the success of any drilling operation. By considering factors such as material, mesh size, and compatibility, operators can significantly enhance the efficiency and effectiveness of their drilling processes. With various options available for sale, investing in quality screens is a crucial step in achieving operational excellence in the oil and gas sector.

-

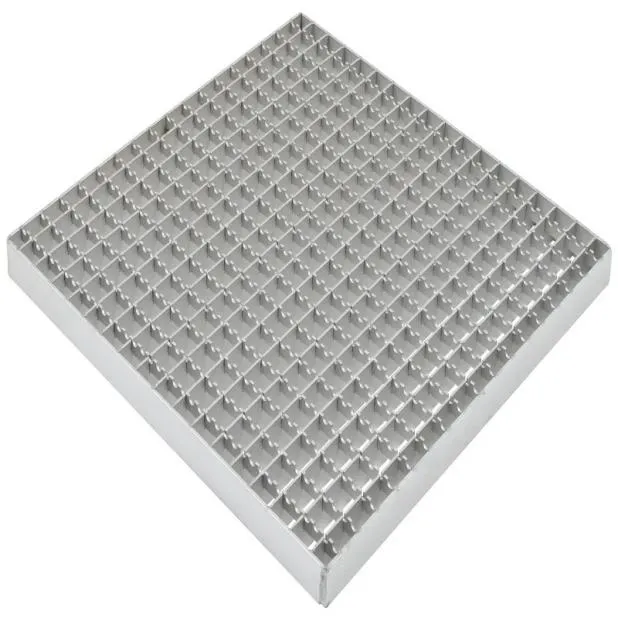

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025