- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

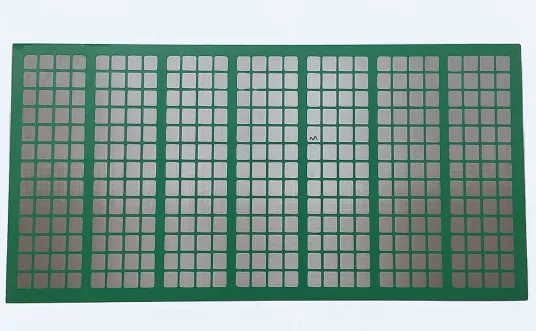

Quality Shale Shaker Screens Available for Purchase at Competitive Prices

Understanding Shale Shaker Screens A Key Component for Efficient Drilling

In the world of oil and gas drilling, one essential piece of equipment often overlooked is the shale shaker screen. These screens play a critical role in the drilling process, particularly in the removal of unwanted solids from the drilling fluid, which is essential to maintain the efficiency and effectiveness of the operation. This article will delve into the importance of shale shaker screens, what to consider when looking for them for sale, and how they contribute to the overall success of drilling activities.

What Is a Shale Shaker Screen?

A shale shaker screen is a component of the shale shaker, which is part of the mud recycling system used in drilling operations. The shale shaker separates the cuttings from the drilling fluid, allowing for the reuse of the fluid, which is crucial for reducing operational costs and environmental impact. The screens are typically made from a combination of metal and synthetic materials, designed to withstand the harsh conditions often associated with drilling, including high temperatures and abrasive materials.

Importance of Shale Shaker Screens

The primary function of shale shaker screens is to filter out solid particles from the drilling mud. This not only helps maintain the viscosity of the drilling fluid but also reduces wear and tear on other equipment involved in the drilling process. Properly functioning shale shaker screens contribute to

1. Cost Efficiency By effectively removing solids, these screens extend the life of the drilling fluid, leading to significant savings in material costs and minimizing the need for frequent fluid replacements.

2. Enhanced Drilling Performance Clean drilling fluid is essential for optimal drilling performance. It improves the rate of penetration and helps prevent potential issues such as wellbore instability.

3. Environmental Protection The reuse of drilling fluids reduces waste, making shale shaker screens an environmentally friendly choice. Efficient solid removal also minimizes the chances of contaminating surrounding ecosystems.

shale shaker screen for sale

Factors to Consider When Buying Shale Shaker Screens

When looking for shale shaker screens for sale, it’s important to consider several factors to ensure you choose the right product for your drilling operation

1. Screen Mesh Size The mesh size determines the size of solids that can be filtered out. It's essential to select the appropriate size based on the type of drilling operation and the characteristics of the formation being drilled.

2. Material and Durability Screens are available in various materials, including stainless steel and synthetic options. Consider the material’s resistance to wear and tear, especially in high-abrasion environments.

3. Compatibility Ensure that the screens are compatible with your shale shaker model. Different shaker models require specific screen dimensions and configurations for optimal performance.

4. Maintenance and Replacement Determine the ease of cleaning and replacing the screens. Regular maintenance is key to keeping the shale shaker functioning optimally.

5. Supplier Reputation It’s always wise to purchase from reputable suppliers who offer quality products backed by warranties and service support.

Conclusion

In conclusion, shale shaker screens are a vital part of the drilling process that can significantly influence the efficiency and success of operations. When searching for shale shaker screens for sale, consider factors such as mesh size, material durability, and compatibility with your existing equipment. By investing in quality shale shaker screens, operators can enhance drilling performance, reduce costs, and contribute to a more sustainable drilling operation. As the demand for efficient and environmentally friendly drilling practices continues to grow, the importance of shale shaker screens will only increase, making them a crucial consideration for any drilling company.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025