- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

High-Quality Shale Shaker Screens Available for Purchase Now

Understanding and Exploring Shale Shaker Screens for Sale

When it comes to the oil and gas drilling industry, the importance of effective separation technologies cannot be understated. Among these technologies, shale shakers play a critical role in the process of drilling fluid management. Shale shaker screens, the heart of these machines, are essential for ensuring efficient drilling operations. In this article, we will delve into the significance of shale shaker screens, their types, and what to consider when looking for shale shaker screens for sale.

What are Shale Shaker Screens?

Shale shaker screens are mesh-like filters that separate solid particles from the liquid drilling fluid (also known as mud) as it emerges from the drilling process. These screens are situated on shale shakers, which are vibrating devices that facilitate the separation. The primary function of these screens is to ensure that the drilling fluid is clean and reusable, which helps minimize costs and reduce environmental impact.

Types of Shale Shaker Screens

There are several types of shale shaker screens available on the market, each designed to meet specific operational needs

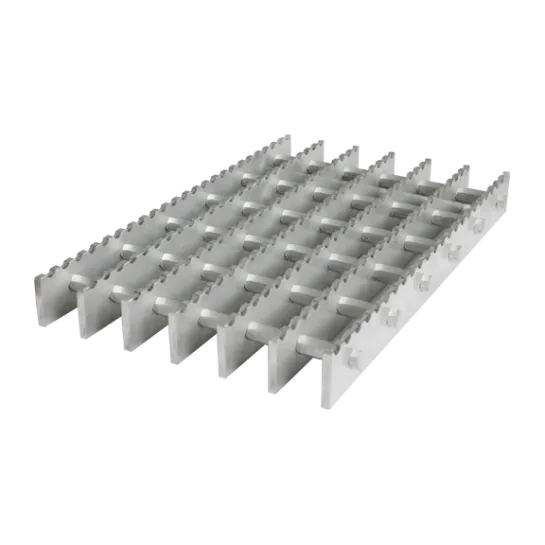

1. Steel Frame Screens These screens are durable and often used in tough drilling environments. They consist of a metal frame that supports the mesh, ensuring strength and stability.

2. Composite Frame Screens These offer a balance between strength and weight. Composite frame screens are less prone to corrosion and can last longer, making them a popular choice for offshore drilling.

3. Woven Mesh Screens Made from metal wires woven together, these screens are effective in filtering out particulates of various sizes. The mesh size can be customized depending on the application.

4. Pre-tensioned Screens These screens are stretched and locked into place without additional support, offering superior durability and higher capacity for drilling fluids.

shale shaker screen for sale

Factors to Consider When Purchasing Shale Shaker Screens

When looking for shale shaker screens for sale, there are several important factors to consider

1. Material The construction material of the screen affects not only its durability but also its performance. Steel and composite frames are common choices; the right one will depend on your specific drilling environment.

2. Mesh Size The mesh size determines the particle size that can pass through the screen. Consider the type of drilling you will be doing to choose a mesh that meets your needs.

3. Size and Compatibility Ensure the screens you choose are compatible with your existing shale shaker. Different shakers may require specific dimensions and designs.

4. Quality and Certification Look for suppliers who offer high-quality, certified products. Quality assurance can significantly impact the efficiency and longevity of the shale shaker screens.

5. Supplier Reputation Research suppliers before making a purchase. Established companies with positive feedback often provide better service and products.

6. Cost While it can be tempting to go for the cheapest option, remember that lower prices may mean compromised quality. Balance cost with performance to ensure a good return on your investment.

7. Support and Warranty Check if the supplier offers technical support or warranties for their products. A good warranty can protect you in case of defects or failure.

Conclusion

In summary, shale shaker screens are vital components of the drilling process, and choosing the right type is crucial for maintaining efficiency and reducing operational costs. As you explore options for shale shaker screens for sale, carefully consider material, mesh size, compatibility, and supplier reputation. Investing time and resources into selecting the best screens can lead to better drilling outcomes and long-term savings. By understanding your needs and utilizing the information outlined above, you can make informed decisions that enhance your drilling operations.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025