- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

Understanding the Functionality and Importance of Shale Shaker Screens in Drilling Operations

The Importance of Shale Shaker Screens in Drilling Operations

In the realm of oil and gas exploration, efficiency and effectiveness are paramount. One of the critical components that ensure these qualities in drilling operations is the shale shaker screen. These screens play a pivotal role in the separation of drilling fluids from the cuttings produced during the drilling process, influencing not only the productivity but also the environmental impact of drilling activities.

Understanding Shale Shaker Screens

Shale shaker screens are integral parts of shale shakers, which are specialized equipment used in the initial phase of the drilling operation. As drilling progresses, solid materials such as rock cuttings are generated. These cuttings must be separated from the drilling fluid—a composition of water, additives, and other elements—so that the fluid can be reused in the drilling process. This is where shale shaker screens come into play.

Typically made from stainless steel or other durable materials, these screens feature a series of mesh panels designed to allow the drilling fluid to pass through while capturing the larger solid particles. The mesh opening size is crucial and can vary based on the type of drilling operation and the specific requirements of the well being drilled.

Types and Specifications

Shale shaker screens come in various designs and specifications to suit different applications. The three primary types include

1. Flat Screens Commonly used in drilling rigs for their versatility and ease of replacement. 2. Elevated Screens These are designed with a slight incline to enhance the separation process by utilizing gravity more effectively. 3. Woven Wire Screens These screens consist of interwoven wires, providing different mesh sizes that can address the specific needs of a drilling operation.

Choosing the right type of screen is critical for optimizing drilling performance. Factors that influence this choice include the type of formation, drilling depth, and the properties of the drilling fluid.

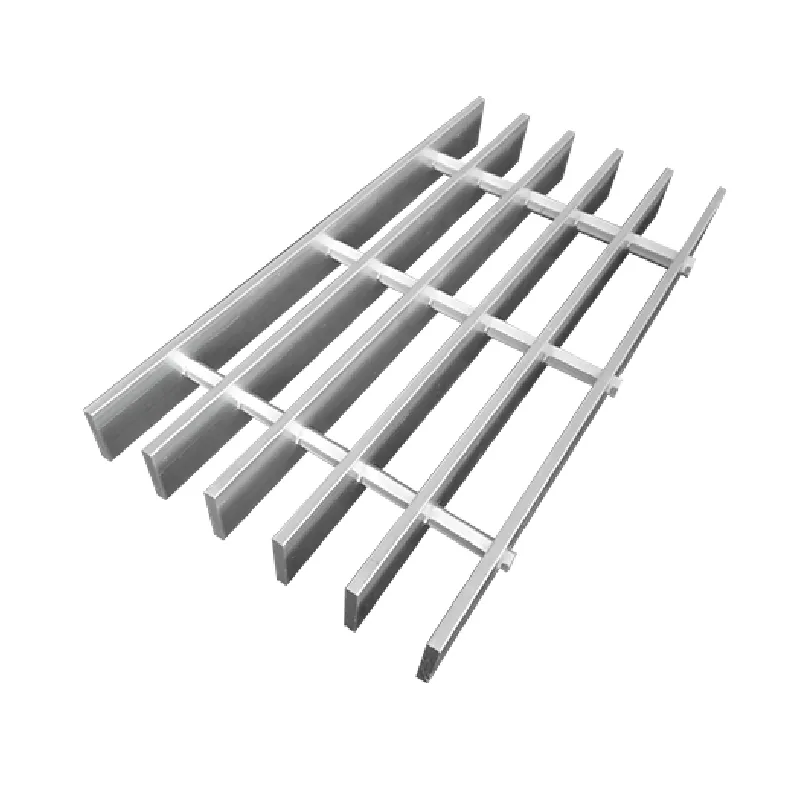

shale shaker screen

Benefits of Using Shale Shaker Screens

The use of shale shaker screens in drilling operations offers several benefits

1. Cost Efficiency By effectively separating solids from drilling fluids, these screens allow for the recycling of drilling fluids. This not only reduces the cost associated with the purchase and disposal of new fluids but also minimizes ecological impact.

2. Improved Drilling Performance Clean drilling fluids enhance the overall efficiency of the drilling process. Clear fluids reduce the resistance during drilling and help in maintaining wellbore stability, which can lead to faster drilling rates and lower operational costs.

3. Environmental Considerations The efficient removal of cuttings from drilling fluids helps to reduce the environmental footprint of drilling operations. By minimizing waste and optimizing the use of resources, operators can adhere to more stringent environmental regulations and promote sustainable practices.

4. Enhanced Equipment Lifespan By preventing larger solids from entering the downstream equipment, shale shaker screens help prolong the life of pumps and other components of the drilling system, leading to lower maintenance costs and downtime.

Conclusion

In summary, shale shaker screens are indispensable in the oil and gas industry, contributing significantly to the efficiency, cost-effectiveness, and sustainability of drilling operations. Their role in separating cuttings from drilling fluids not only facilitates equipment performance but also ensures that environmental standards are met. As drilling technology continues to advance, the development of more sophisticated shale shaker screens is likely to enhance productivity further, ensuring that future drilling operations remain efficient, environmentally friendly, and economically viable. Understanding and selecting the appropriate shale shaker screens can make a notable difference in the success of drilling projects, making them a focal point in the optimization of drilling performance.

-

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025