- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

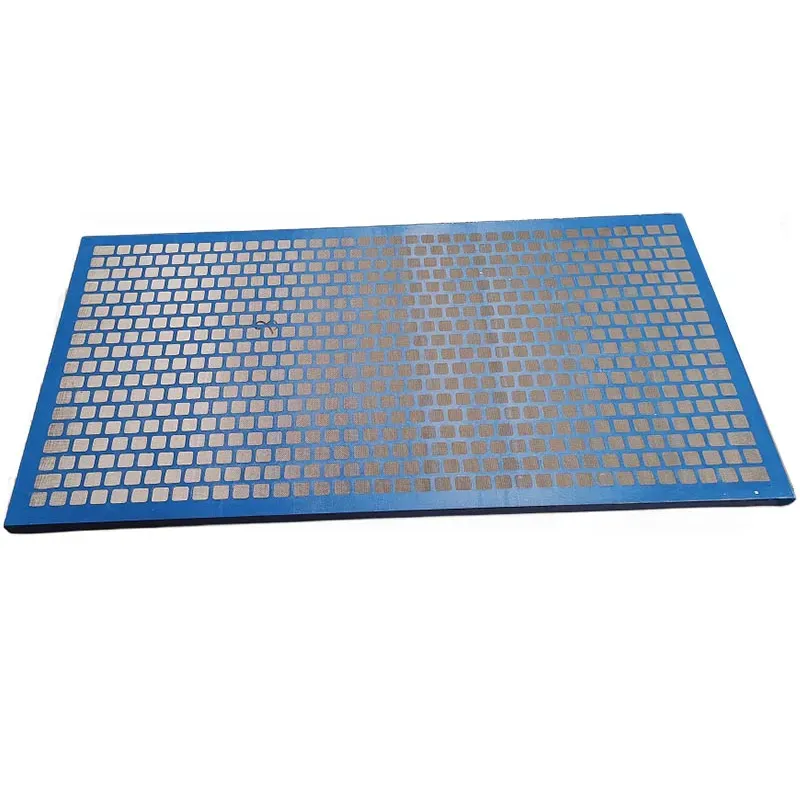

Shale Shaker Screens for Challenging Drilling Environments

Efficient solids control systems are critical for successful oil and gas drilling operations, particularly in challenging environments. The shale shaker screen is a key component of this system, designed to separate solids from drilling fluid, ensuring smooth operation and reducing wear on downstream equipment. In this article, we’ll explore how swaco shaker screens, advanced shale shaker screen mesh, and durable shale shaker screen material provide effective solutions for high-demand drilling conditions.

The Importance of Shale Shaker Screens in Solids Control

The shale shaker screen is the first line of defense in solids control, playing a vital role in maintaining drilling efficiency. These screens filter out cuttings and other unwanted solids from the drilling fluid, allowing the fluid to be recycled and reused.

For operations in extreme environments, shaker screens must be robust enough to handle high volumes of fluid and abrasive materials without compromising performance. Modern designs, like swaco shaker screens, feature high-strength meshes and enhanced durability to meet the demands of oil and gas exploration.

Advancements in Shale Shaker Screen Mesh

One of the key features determining the performance of a shale screen is the quality of the shale shaker screen mesh. Mesh size affects both the filtration efficiency and fluid throughput. Operators must carefully select a mesh size that balances these factors, ensuring clean fluid while maintaining operational speed.

High-performance shale shaker screen mesh often includes multi-layered configurations, combining coarse and fine meshes for optimal separation. These meshes are reinforced to withstand wear and tear from abrasive particles, ensuring consistent performance over time.

Durable Shale Shaker Screen Material for Longevity

The material used in shale shaker screens directly impacts their longevity and effectiveness. Commonly used materials include:

- Stainless Steel: This material offers excellent resistance to corrosion and mechanical wear, making it ideal for harsh environments.

- Composite Materials: Lightweight and durable, composite shale shaker screen materialis less prone to warping and can extend the lifespan of the screen.

- Hybrid Designs: Combining the strengths of different materials, hybrid shaker screensdeliver superior performance in high-demand operations.

By choosing the right shale shaker screen material, operators can reduce replacement frequency and operational costs while maintaining high filtration efficiency.

Why Swaco Shaker Screens Lead the Market

Swaco shaker screens are renowned for their innovative designs and unmatched reliability. Engineered to handle the rigors of oil and gas drilling, these screens incorporate advanced technology to optimize solids removal and fluid recovery.

Their features include:

Quick-change designs for easy replacement.

Enhanced mesh bonding to prevent delamination.

Rugged frames that provide structural integrity under heavy loads.

With their proven track record, swaco shaker screens are a trusted choice for operators seeking high performance in challenging environments.

Key Considerations for Choosing Shale Shaker Screens

Selecting the right shale shaker screen is essential for achieving optimal performance in solids control systems. Here are the main factors to consider:

- Compatibility: Ensure that the screen fits your shaker model and meets the specifications of your drilling rig.

- Mesh Size: Choose a shale shaker screen meshthat provides the desired level of filtration without compromising fluid flow.

- Material Durability: Opt for shale shaker screen materialthat can withstand abrasive conditions and corrosive fluids.

- Cost-Effectiveness: Evaluate the screen’s lifespan and performance to ensure long-term savings.

By taking these factors into account, operators can maximize the efficiency of their solids control systems while minimizing operational disruptions.

In the demanding field of oil and gas exploration, high-quality shale shaker screens are essential for maintaining efficient operations. Whether you’re using swaco shaker screens, advanced shale shaker screen mesh, or innovative shale shaker screen material, investing in the right equipment ensures durability, performance, and cost savings. By understanding the critical factors that influence screen selection and performance, operators can confidently tackle the challenges of modern drilling environments. With the right shaker screen solutions, success in even the most extreme conditions becomes achievable.

-

The Versatility of Steel Walkway GratingNewsAug.07,2025

-

The Benefits of Galvanized Steel Grating for Your ProjectsNewsAug.07,2025

-

Shaker Screens: The Ultimate Solution for Your Drilling NeedsNewsAug.07,2025

-

Perimeter Safety Net: An Essential Solution for Helipad SafetyNewsAug.07,2025

-

Enhance Safety and Efficiency with Steel Walkway GratingNewsAug.07,2025

-

Discover Exceptional Steel Grating for SaleNewsAug.07,2025