- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Shale Shaker Screen with API Mesh, Longer Life?

Hook Strip Soft Screen: field notes, specs, and what really matters on the shaker

If you’ve spent time on a rig, you already know the humble shale shaker screen makes or breaks your mud program. The Hook Strip Soft Screen from HF PetroMesh comes from the industrial zone south of Anping Town, Hengshui, Hebei, China—a place that, to be honest, has screen craft in its DNA. I’ve walked those workshops: rows of stainless mesh, careful layering, and techs who can eyeball mesh flaws from five meters away. Surprisingly old-school in some ways, but the results are consistent.

What it is and where it fits

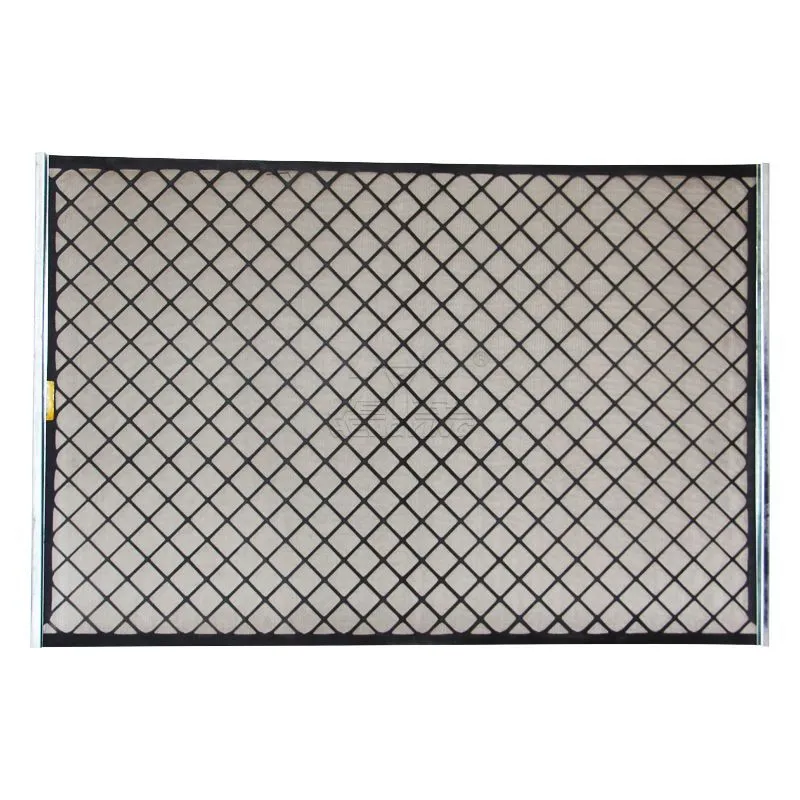

This soft-surface screen is built for oil and gas drilling, HDD, geothermal, and trenchless projects where fine cuttings control matters but you still want fast changes and a forgiving fit. The soft design (no rigid frame) mounts via hook strips; less weight, easier handling, and in many cases, better conformance to the shaker bed. Many customers say screen blinding is lower than expected on water-based mud—on oil-based, it depends on the solids and emulsifier package.

Materials, build, and process flow (the short version)

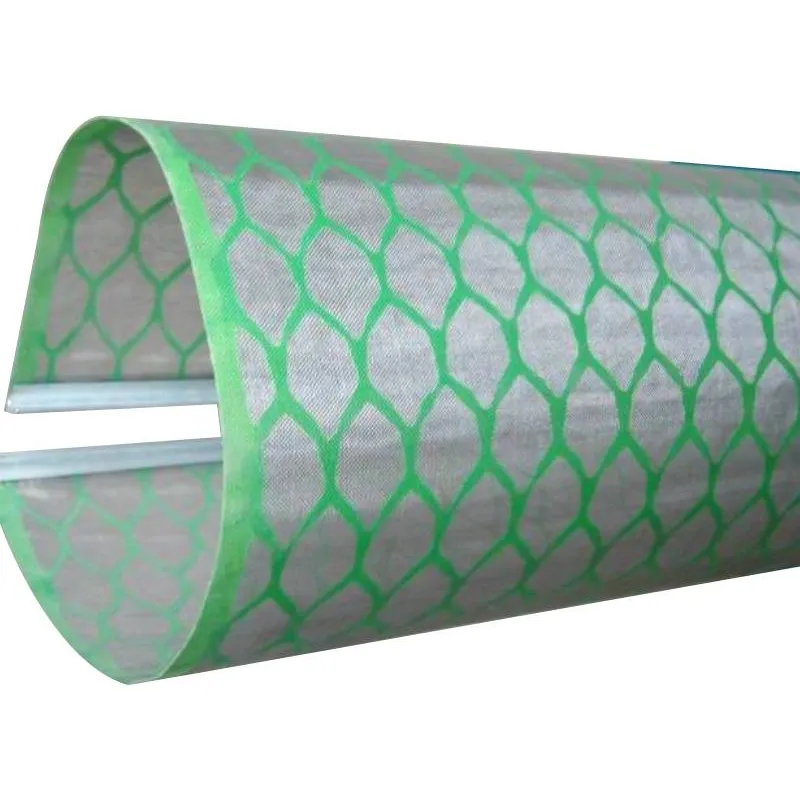

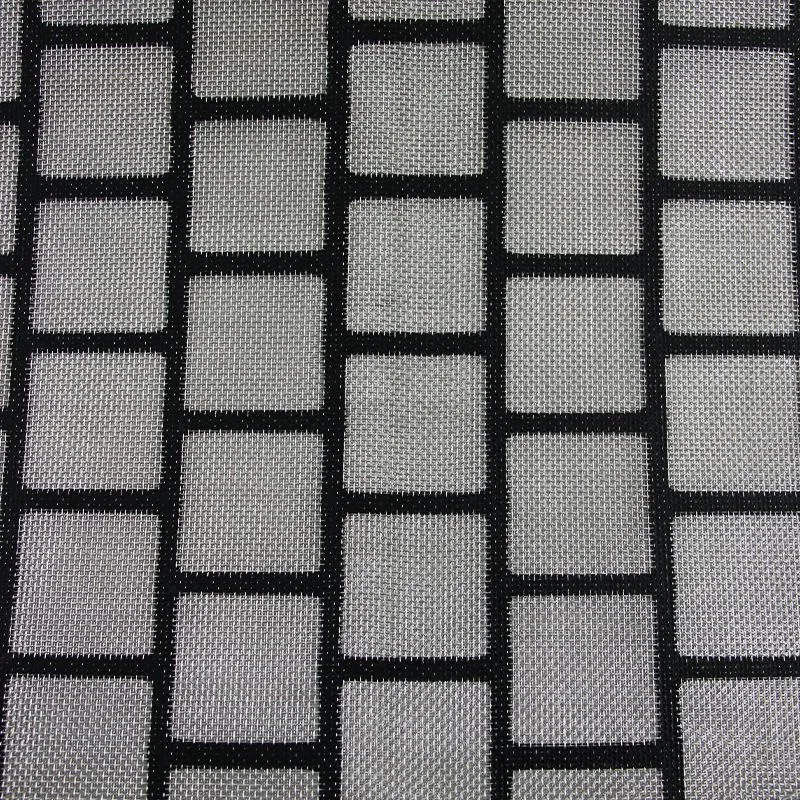

- Wire cloth: SS304 or SS316 stainless steel, 2–3 layers, calibrated to API RP 13C.

- Bonding: high-strength epoxy + thermal set adhesive; real-world use may vary with mud temperature.

- Edges/hooks: cold-formed steel hooks with anti-corrosion coating.

- QC methods: wet sieving for cut point (D50), non-blanked area measurement, visual mesh integrity check, salt-spray on hardware (≈48–96 hrs as needed).

Service life: around 120–300 operating hours per panel in average WBM; OBM and high-LGS situations can shorten that—no screen works miracles when unweighted solids climb. However, with a good dilution plan and desanding upstream, I’ve seen these run a full week without a tear.

Key specs and options

| Parameter | Typical Value | Notes |

| API Designation | API 20–API 230 | Tested per API RP 13C; D50 ranges ≈ 74–68 µm (API 200 example) |

| Non-blanked Area | ≈ 4.0–6.2 ft² (size-dependent) | Soft screen geometry improves usable area |

| Layers | 2–3 | Top fine mesh + support mesh |

| Materials | SS304/SS316, epoxy | 316 recommended for corrosive brines |

| Customization | Size, mesh count, hook type | OEM shaker compatibility on request |

Test data and field feedback

Internal QC (Q2 2024) showed API 140 panels at D50 ≈ 104–114 µm with conductance in the mid-range for soft screens; solids loading at 6–8 g/L WBM stayed stable across a 6-hour run. A drilling supervisor in Oman told me, “We ran the shale shaker screen at 45 Hz; fewer bypass events than our previous batch, and faster change-outs.” Another North Sea HDD client noted slightly better dryness in near-surface clay—could be mud chemistry helping, but still, a good sign.

Vendor snapshot: how it stacks up

| Vendor | API Labeling | Avg. Non-blanked Area | Typical Lead Time | Notes |

| HF PetroMesh (Hook Strip Soft Screen) | Full API RP 13C tags | High (≈ by size) | 7–15 days | Good price-to-life ratio |

| Vendor A (generic) | Partial compliance | Medium | 10–20 days | Lower cost; variable QC |

| Vendor B (premium) | Full API + traceability | Medium–High | 15–30 days | Excellent durability; higher price |

Applications and advantages

- Oil & gas drilling, HDD, geothermal, trenchless tunneling.

- Advantages: fast install, larger effective area, stable D50, and lighter handling. In fact, crews appreciate the reduced change-out time.

- Certifications: plant-level ISO 9001; API RP 13C-compliant labeling; RoHS materials on request.

Quick case study

West Texas, WBM 9.6 ppg, API 140 shale shaker screen on a dual-deck shaker. After switching from a heavier steel-frame panel, the rig cut change-out time by ≈25% and improved dilution rate by ≈8% thanks to steadier cuttings removal. Not dramatic, but the daily mud bill noticed.

Customization

Sizes to match popular shakers, mesh counts from API 20 to 230, SS304 or SS316, and hook styles tailored to your deck. If your mud program is unique (glycerin or brine-heavy), specify chemistry and temp so the adhesive stack is tuned—small detail, big difference.

Origin: Industrial zone, South of Anping Town, Hengshui, Hebei, China.

Authoritative citations

- API RP 13C: Recommended Practice on Drilling Fluids Processing Systems—Shale Shaker Screen Labeling and Testing.

- ISO 9001:2015 Quality Management Systems—Requirements.

- Spearing, P. et al., SPE papers on solids control efficiency and screen selection (various years), Society of Petroleum Engineers.

- OSHA/NIOSH drilling best practices for solids handling and rig ergonomics (for change-out safety context).

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025