- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Shale Shaker Screen-Hangshun Wire Mesh|Precision Filtration&Drilling Efficiency

Introduction

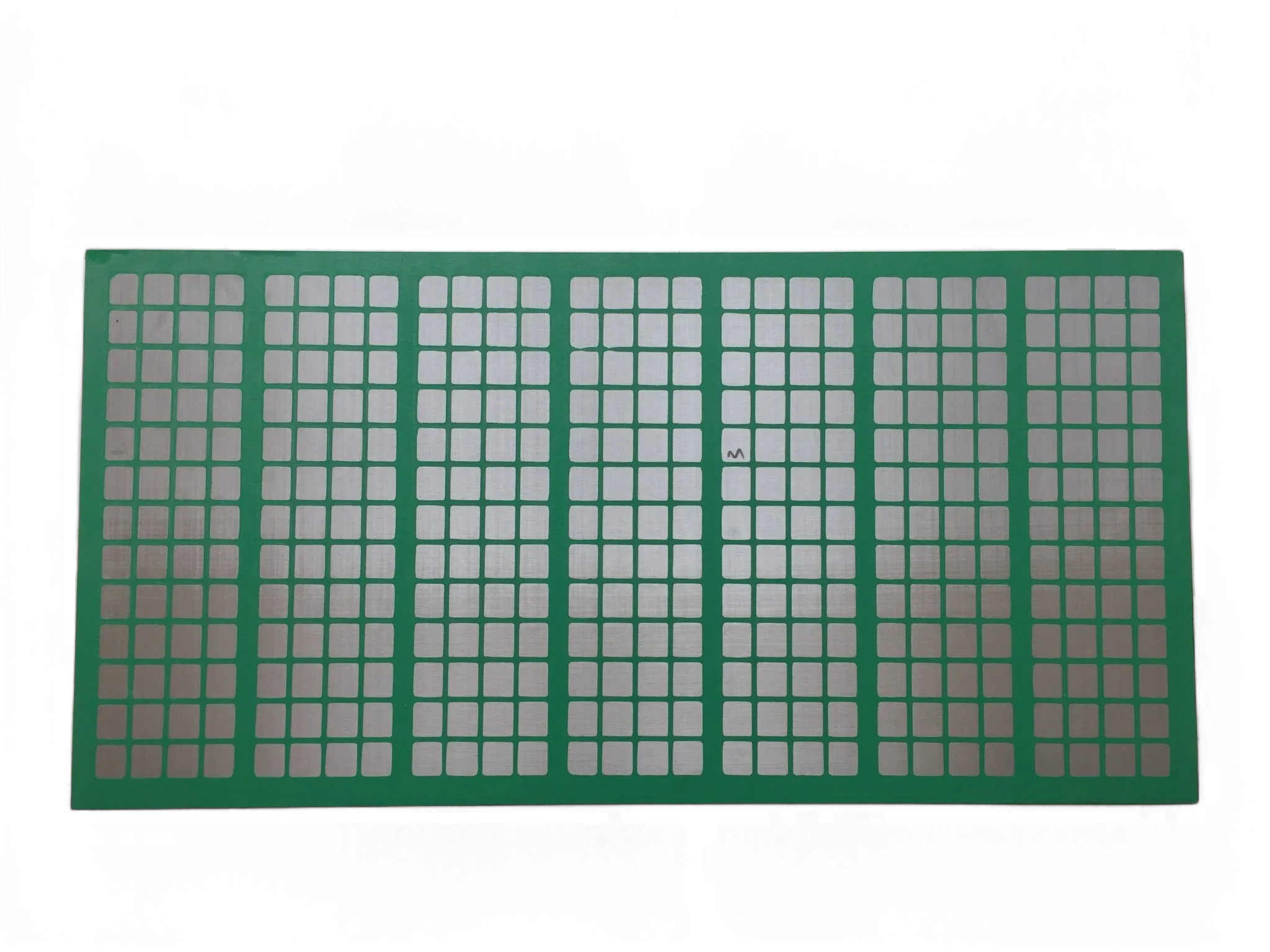

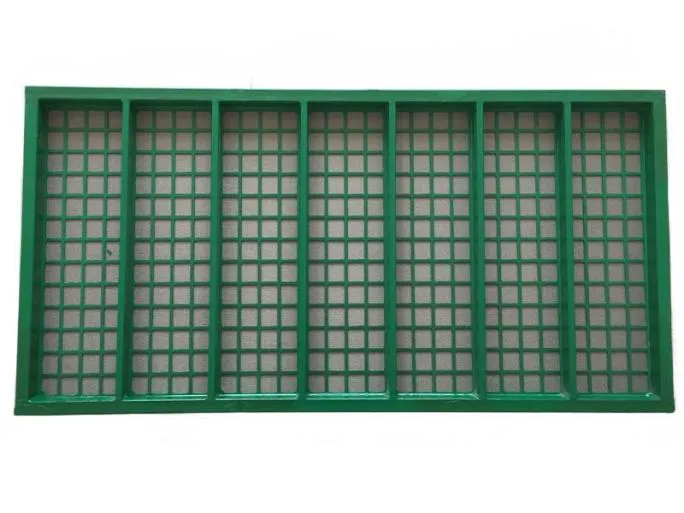

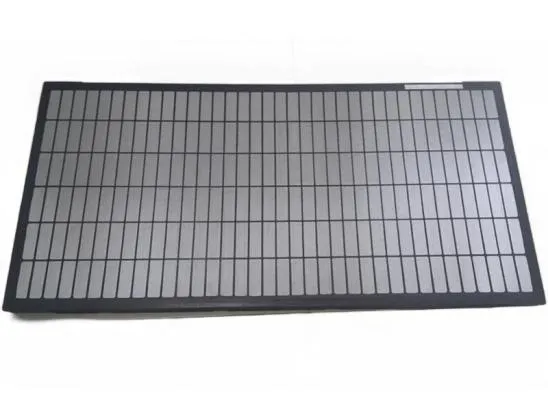

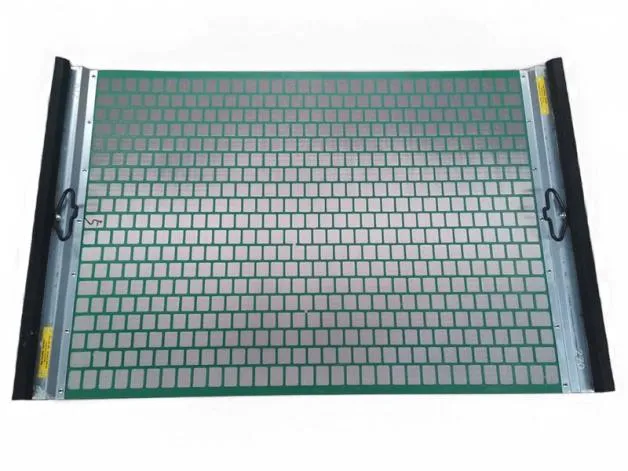

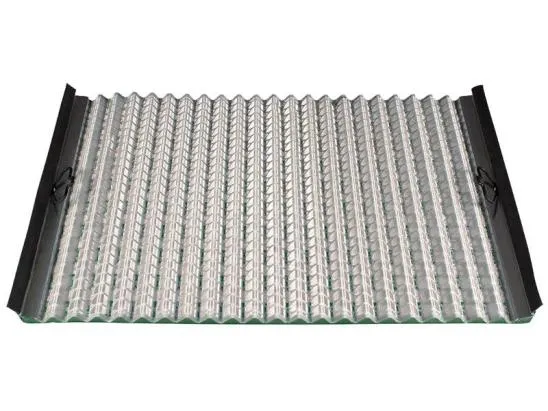

The Shale Shaker Screen is a critical component in drilling operations, designed to filter and separate drilling cuttings from mud (drilling fluid). This fine mesh, often composed of multiple layers of stainless steel wire cloth, plays a pivotal role in maintaining the efficiency of shale shakers. By capturing solid particles and allowing excess mud to drain, the Shale Shaker Screen ensures optimal performance in various drilling environments.

Key Features of the Shale Shaker Screen

- High Strength and Bearing Capacity: The Shale Shaker Screen is engineered to withstand heavy drilling loads, ensuring durability in demanding conditions.

- Exceptional Filtering Accuracy: With dual or triple-layered stainless steel wire cloth, the screen provides precise separation of solids from drilling fluid, minimizing contamination.

- Superior Processing Efficiency: The design of the Shale Shaker Screen enhances the rate at which cuttings are processed, reducing downtime and improving operational efficiency.

- Wear and Corrosion Resistance: The use of high-quality materials ensures longevity, even in harsh environments where exposure to chemicals and abrasives is common.

- Flexibility and Adaptability: Available in various configurations (e.g., steel frame, composite frame, wave screen), the Shale Shaker Screen can be tailored to specific drilling conditions.

- Easy Installation and Maintenance: The screen’s user-friendly design allows for quick replacement and minimal maintenance, reducing operational costs.

Technical Specifications

| Parameter | Details |

|---|---|

| Material | Stainless steel, carbon steel |

| Surface Treatment | Coating (black, green, blue; customizable) |

| Production Process | Weaving and perforating |

| Type | Steel or composite frame screen, hook strip screen, wave screen |

| Standards | ISO 13501, API RP 13C, GBT 11648, GBT 11650 |

Applications in the Oil and Gas Industry

The Shale Shaker Screen is widely utilized in various drilling operations, including:

- Oil Drilling: Essential for separating cuttings from drilling fluid in both onshore and offshore rigs.

- Non-Excavation Horizontal Directional Drilling: Ensures efficient mud purification during trenchless construction.

- Coal Bed Methane Drilling: Maintains fluid quality in low-pressure environments.

- Shale Gas Drilling: Critical for handling high-volume cuttings in unconventional gas extraction.

- Environmental Protection: Used in river sludge treatment to prevent contamination of water bodies.

Company Background: Anping County Hangshun Wire Mesh Manufacture Co., Ltd.

Founded in Anping County Hangshun Wire Mesh Manufacture Co., Ltd., this company specializes in producing high-quality Shale Shaker Screens tailored for the oil and gas industry. With a commitment to innovation and precision, the company adheres to international standards such as ISO 13501 and API RP 13C, ensuring that their products meet the rigorous demands of modern drilling operations. Their expertise in manufacturing woven metal screens has established them as a trusted supplier in the global market.

Why Choose the Shale Shaker Screen?

The Shale Shaker Screen offers a combination of durability, efficiency, and adaptability that sets it apart from conventional filtration systems. Its multi-layered design ensures superior performance in separating fine particles, while its resistance to wear and corrosion extends its service life. Additionally, the availability of multiple configurations allows for seamless integration into existing drilling setups, making it a versatile solution for operators.

Industry Standards and Certifications

The Shale Shaker Screen complies with stringent industry standards, including NIST-recognized specifications. According to the National Institute of Standards and Technology (NIST), adherence to standards like ISO 13501 and API RP 13C is essential for ensuring the reliability and safety of industrial equipment [1]. These standards provide a framework for quality control, guaranteeing that the Shale Shaker Screen meets the highest performance benchmarks.

References:

- NIST: National Institute of Standards and Technology. Retrieved from https://www.nist.gov.

-

Shaker Screen for Sale – Durable, API-Rated, Fast ShippingNewsNov.17,2025

-

Industrial Steel Grating — Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Industrial Steel Grating: Durable, Anti-Slip, GalvanizedNewsNov.17,2025

-

Shale Shaker Screen – Durable Mesh, Factory Price, OEMNewsNov.17,2025

-

Shale Shaker Screen Factory | API Quality, OEM, Fast ShipNewsNov.17,2025

-

Metal Grating for Sale – In Stock, Custom Sizes, Quick ShipNewsNov.10,2025