- Industrial zone, South of Anping Town, Hengshui, Hebei, China.

- sales@hfpetromesh.com

- +86-18931809706

Afrikaans

Afrikaans  Albanian

Albanian  Amharic

Amharic  Arabic

Arabic  Armenian

Armenian  Azerbaijani

Azerbaijani  Basque

Basque  Belarusian

Belarusian  Bengali

Bengali  Bosnian

Bosnian  Bulgarian

Bulgarian  Catalan

Catalan  Cebuano

Cebuano  Corsican

Corsican  Croatian

Croatian  Czech

Czech  Danish

Danish  Dutch

Dutch  English

English  Esperanto

Esperanto  Estonian

Estonian  Finnish

Finnish  French

French  Frisian

Frisian  Galician

Galician  Georgian

Georgian  German

German  Greek

Greek  Gujarati

Gujarati  Haitian Creole

Haitian Creole  hausa

hausa  hawaiian

hawaiian  Hebrew

Hebrew  Hindi

Hindi  Miao

Miao  Hungarian

Hungarian  Icelandic

Icelandic  igbo

igbo  Indonesian

Indonesian  irish

irish  Italian

Italian  Japanese

Japanese  Javanese

Javanese  Kannada

Kannada  kazakh

kazakh  Khmer

Khmer  Rwandese

Rwandese  Korean

Korean  Kurdish

Kurdish  Kyrgyz

Kyrgyz  Lao

Lao  Latin

Latin  Latvian

Latvian  Lithuanian

Lithuanian  Luxembourgish

Luxembourgish  Macedonian

Macedonian  Malgashi

Malgashi  Malay

Malay  Malayalam

Malayalam  Maltese

Maltese  Maori

Maori  Marathi

Marathi  Mongolian

Mongolian  Myanmar

Myanmar  Nepali

Nepali  Norwegian

Norwegian  Norwegian

Norwegian  Occitan

Occitan  Pashto

Pashto  Persian

Persian  Polish

Polish  Portuguese

Portuguese  Punjabi

Punjabi  Romanian

Romanian  Russian

Russian  Samoan

Samoan  Scottish Gaelic

Scottish Gaelic  Serbian

Serbian  Sesotho

Sesotho  Shona

Shona  Sindhi

Sindhi  Sinhala

Sinhala  Slovak

Slovak  Slovenian

Slovenian  Somali

Somali  Spanish

Spanish  Sundanese

Sundanese  Swahili

Swahili  Swedish

Swedish  Tagalog

Tagalog  Tajik

Tajik  Tamil

Tamil  Tatar

Tatar  Telugu

Telugu  Thai

Thai  Turkish

Turkish  Turkmen

Turkmen  Ukrainian

Ukrainian  Urdu

Urdu  Uighur

Uighur  Uzbek

Uzbek  Vietnamese

Vietnamese  Welsh

Welsh  Bantu

Bantu  Yiddish

Yiddish  Yoruba

Yoruba  Zulu

Zulu

- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

- Zulu

shale shaker screen factory

Shale Shaker Screen Factory Innovations in Oil and Gas Drilling

The oil and gas industry is a cornerstone of the global economy, and its operations are heavily reliant on efficient and effective equipment. One critical component in the drilling process is the shale shaker screen, which plays a pivotal role in separating solid materials from drilling fluids. As demand for oil and gas continues to rise, the importance of specialized manufacturing facilities, like shale shaker screen factories, has become increasingly vital.

Shale shaker screens are designed to withstand the harsh conditions of drilling operations while ensuring maximum fluid recovery and waste management. These screens must be durable, reliable, and capable of handling various types of drilling mud. The manufacturing process of these screens involves several stages, including design, material selection, production, and quality control.

In a typical shale shaker screen factory, advanced technologies are employed to enhance the manufacturing process. For example, computer-aided design (CAD) software is used to create precise screen specifications tailored to the specific needs of different drilling operations. This ensures that the screens produced are efficient and effective in their intended applications.

Material selection is another crucial aspect of producing high-quality shale shaker screens. Manufacturers often choose from a variety of materials, including stainless steel and synthetic compounds, to produce screens that offer the best combination of strength, flexibility, and resistance to wear and tear. High-quality mesh and perforated plate designs are essential for optimal filtration performance, and factories invest in state-of-the-art weaving technologies to achieve the desired precision.

shale shaker screen factory

Quality control is paramount in the production of shale shaker screens. Each screen undergoes rigorous testing to ensure it meets industry standards and specifications. This includes tests for tensile strength, mesh size, and durability under varying operational conditions. Furthermore, many factories adhere to international quality standards such as ISO certification, demonstrating their commitment to producing reliable and efficient products.

The role of a shale shaker screen factory extends beyond manufacturing; it also involves innovation and adaptation to the changing needs of the oil and gas industry. As drilling techniques evolve and new challenges emerge, manufacturers continually research and develop new screen designs and materials that enhance performance. This commitment to innovation helps operators improve their drilling efficiency and reduce waste.

In addition, environmental considerations have become increasingly important in the oil and gas sector. Shale shaker screen factories are now focusing on producing screens that not only perform well but also minimize environmental impact. By developing screens that enhance fluid recovery and reduce the volume of waste materials, these manufacturers contribute to more environmentally friendly drilling practices.

In conclusion, shale shaker screen factories play a significant role in the oil and gas industry by providing essential components that enhance drilling efficiency and waste management. Through advanced manufacturing techniques, rigorous quality control, and a focus on innovation, these factories are well-equipped to meet the challenges of an ever-evolving industry. As the demand for energy continues to grow, the capabilities of shale shaker screens will undoubtedly play a crucial role in shaping the future of oil and gas drilling operations.

-

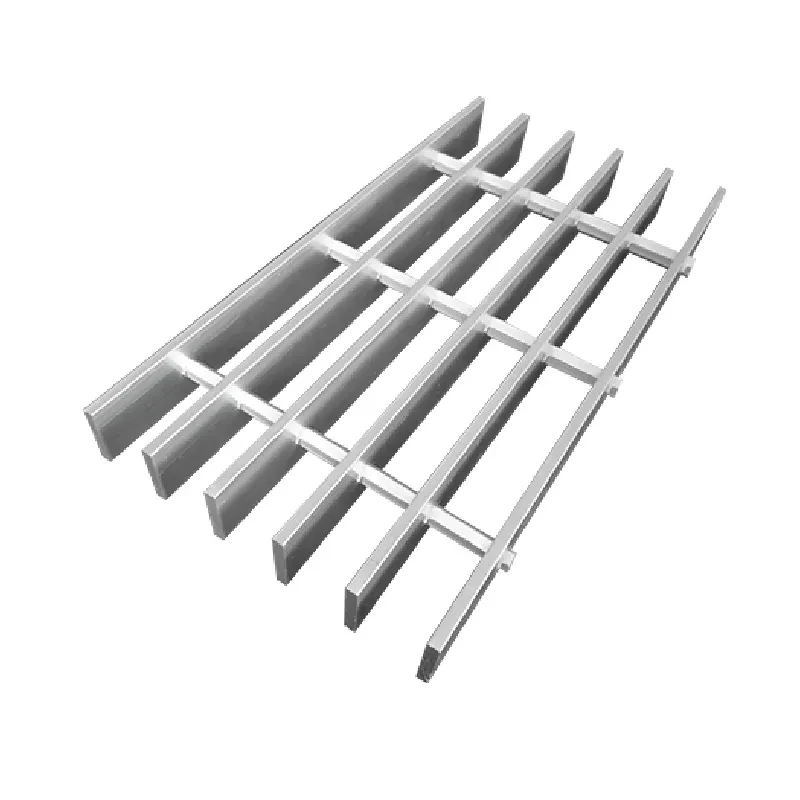

Welded Steel Bar Grating: The Rugged Industrial Flooring Solution Built for Load and LongevityNewsJun.24,2025

-

Steel Walkway Grating: Reliable, Resilient, and Built for Every StepNewsJun.24,2025

-

Shale Shaker Screen for Sale: Optimize Drilling Efficiency with Precision Screening PowerNewsJun.24,2025

-

Shaker Screen for Sale: Elevate Your Drilling Efficiency with Durable Separation SolutionsNewsJun.24,2025

-

Press Locked Steel Grating: Industrial Strength with Precision Fit for Heavy-Duty ApplicationsNewsJun.24,2025

-

Perimeter Safety Netting: The Critical Safety Upgrade for Every HelipadNewsJun.24,2025